TM 55-1930-203-10

Table 3-2. TROUBLESHOOTING - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3.

ABNORMAL ENGINE COOLANT TEMPERATURES (cont'd)

Step 2. Inspect for low oil level with the dipstick.

Add oil as required.

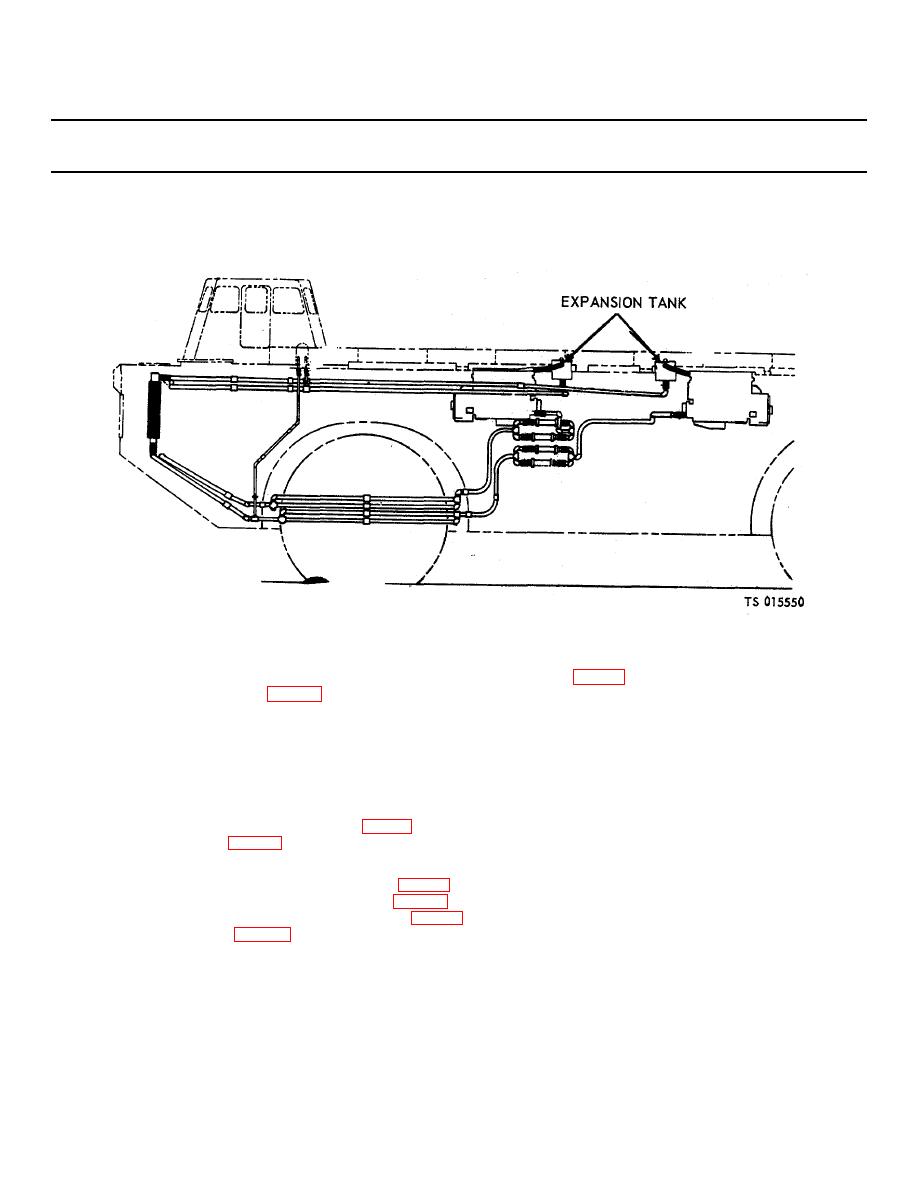

Step 3. Inspect for defective expansion tank pressure cap by watching for overflow when engine is shut off.

Replace pressure cap. If malfunction is not corrected, report to organizational maintenance.

Figure 3-12. Expansion tank.

4.

ENGINE SMOKES EXCESSIVELY

If smoke is black, inspect for partly closed emergency engine shutoff lever (fig. 3-4).

a.

Return lever (fig. 3-4) to down (or run) position. If malfunction is not corrected, report to organizational

maintenance.

b. If smoke is blue (engine burning oil), report to organizational maintenance.

5.

LOW ENGINE OIL PRESSURE

Inspect for low oil level with dipstick.

Add oil as required. If malfunction is not corrected, report to organizational maintenance.

6.

TIRE(S) FAIL TO INFLATE

Inspect for closed tire air shutoff valves (fig. 3-8).

Open valves (fig. 3-8). If malfunction is not corrected, report to organizational maintenance.

7.

TIRE(S) FAIL TO DEFLATE

Depress and lock tire inflation valves (fig. 3-7) in deflate position.

Open valves (fig. 3-8). If malfunction is not corrected, report to organizational maintenance.

8.

RAMP WILL NOT FULLY CLOSE

Check for obstruction between ramp and ramp seal.

Remove obstruction. Make sure ramp sea] is not damaged. If malfunction is not corrected, report to organizational

maintenance.

9.

MARINE STEERING NOT TRUE

Inspect rudders at rear of LARC for obstructions such as stones, pebbles or seaweed.

Remove obstruction from rudders. If malfunction is not corrected, report to organizational maintenance.

3-36