TM 554920-384-13&P

50

100

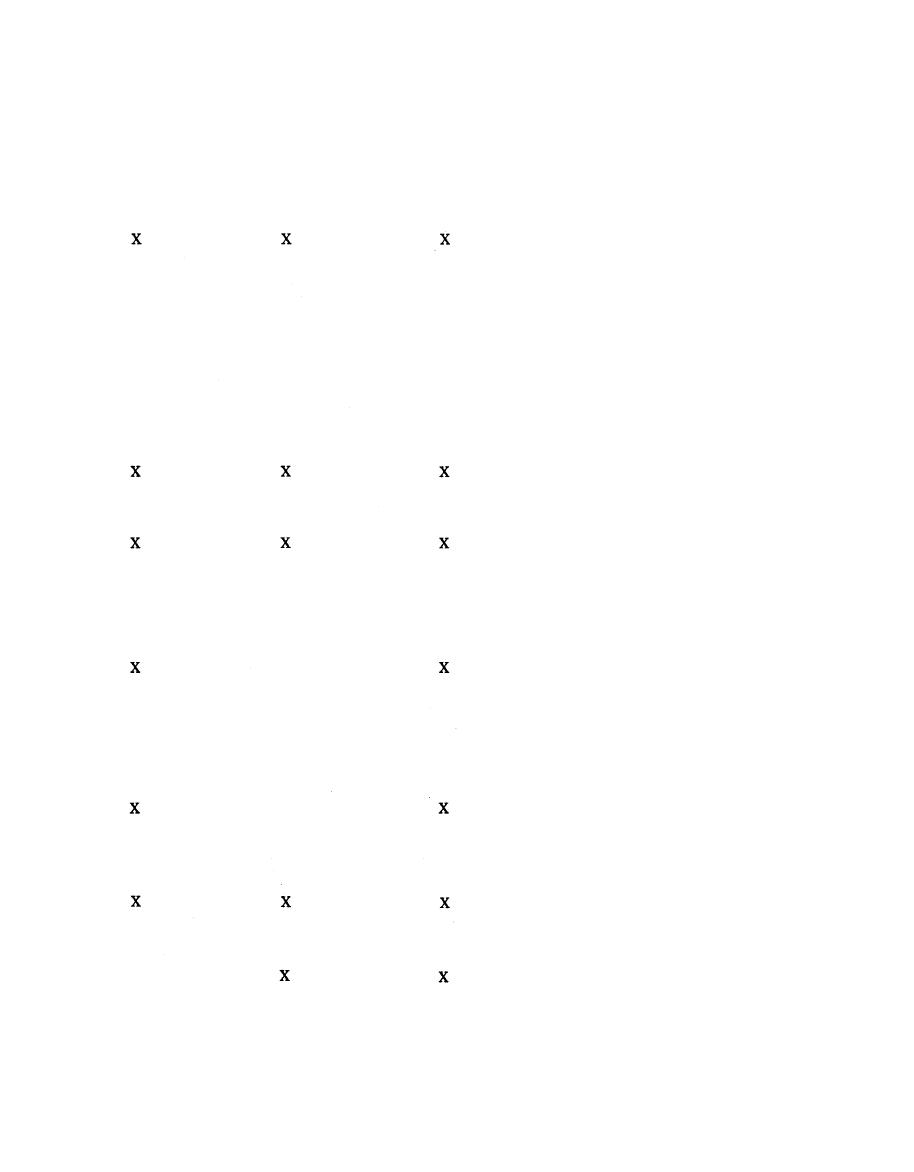

GENERAL

INSPECTION

HOUR

HOUR

Appearance. Inspect the general appear-

ance of the equipment, paying particular at-

tention to cleanliness, legibility of identi-

fication markings, and conditions of the

paint. Correct all deficiencies noticed.

C y l i n d e r head, manifold, and muf-

fler. Inspect the cylinder heads, manifolds

and muffler for leaks, loose mounting and

defective gaskets. Tighten loose manifolds

and muffler mounting bolts and nuts. Dur-

ing the first weekly servicing of a new or

reconditioned engine, inspect all the cylin-

der head bolts for tightness. After warming

the engine up to operating temperature,

tighten any loose bolts to 25 to 32 ft.-lb

torque. Replace defective cylinder head and

manifold gaskets.

Valve Mechanism. If the valves are noisy or

loss of power is noticed, inspect the condi-

tion of the valve mechanism.

Remove valve covers and adjust valve lifter

clearance if necessary. The correct clear-

ance for the valve lifters is 0.0080 inch for

the intake valves and 0.0160 inch for the ex-

haust valves. Replace cover gaskets if

defective.

Compression Test. Remove the spark plugs

and test the cylinder compression by turn-

ing the engine ocver serveral times to sta-

bilize gage reading. If the gage reading var-

ies more than 10 pounds between the four

cylinders, inspect the cylinder head bolts for

tightness.

Tighten any loose bolts and retest. If low

compression or a variation in compression

persists the trouble lies with the cylinder

head gasket, valves, or piston rings. Correct

all deficiencies.

Electrical System Magneto. Inspect the ig-

nition magneto for loose mounting bolts and

wiring connections. Correct any deficiencies

notes.

Remove the end cap and inspect the distrib-

utor cap for cracks, and corroded termi-

nals. Examine the breaker point gap. The

correct gap is 0.015 inch at full separation

of points.

4-2