TM 9-2330-235-14&P

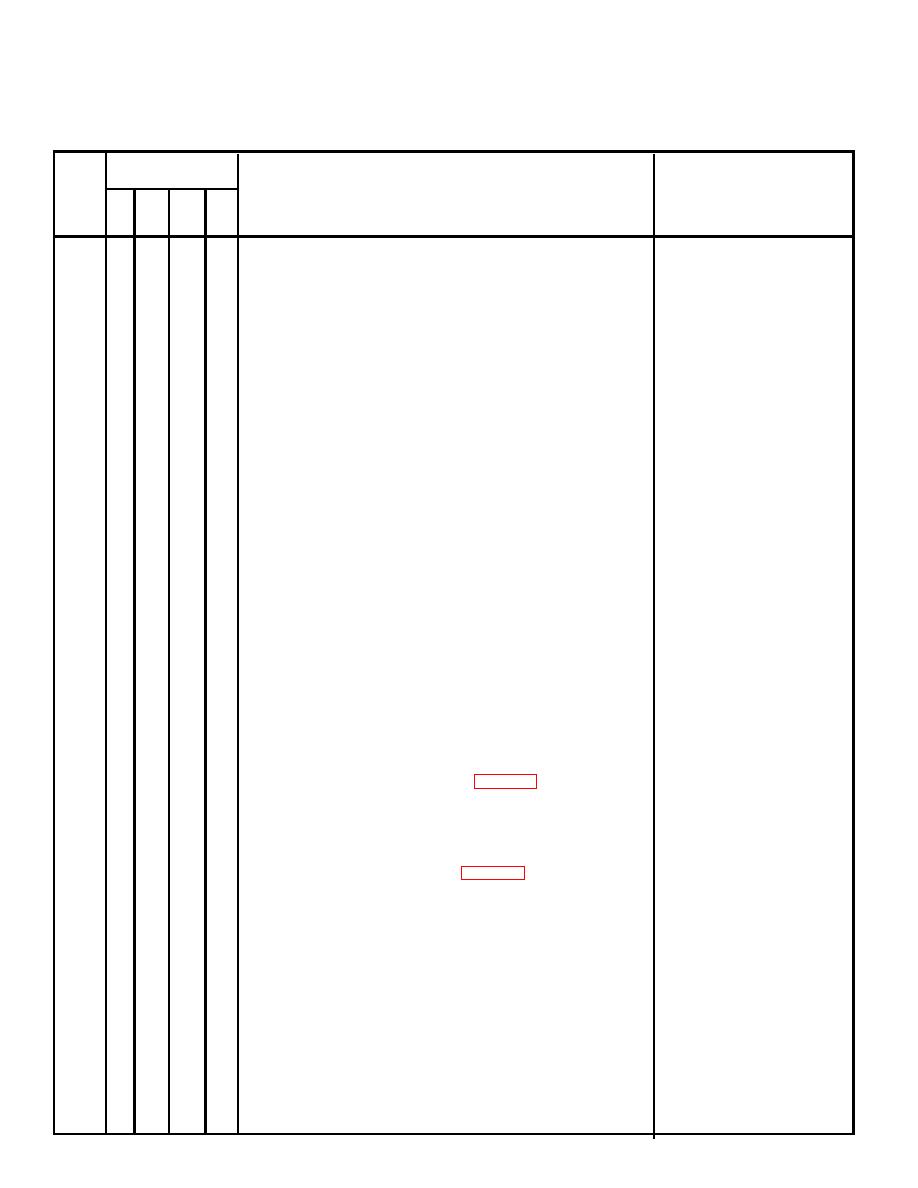

Table 2-1.

Operator/Crew Preventive Maintenance Checks and Services (PMCS) (Con't).

B-Before

D-During

A-After

W-Weekly

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

ITEM B

D

A

W PROCEDURE: CHECK FOR AND HAVE REPAIRED, FILLED, OR

READY/AVAILABLE IF

NO.

adjusted as needed.

2

WHEELS

Check wheels for damage. Ensure that all wheel stud

Two or more wheel stud nuts

nuts are present and secure. If wheel stud nuts are

missing on one wheel.

obviously loose, notify Organizational Maintenance to

apply proper torque.

3

INTERVEHICULAR AIR HOSE

Ensure that intervehicular air hose is in good condition

Missing or damaged air hose or

and securely connected. Check for missing or

air coupling preformed packing.

damaged air coupling preformed packing.

4

INTERVEHICULAR CABLE

Ensure that intervehicular cable is in good condition

and connectors are correctly connected and secured

in mounting clips.

5

HYDRAULIC BRAKE SYSTEM LINES AND FIT-

TINGS

Check under trailer and around fittings for signs of

Any leaks are found.

leaks.

6

FRAME AND TOWING ATTACHMENTS

a. Visually check frame for cracks or broken welds.

Frame is cracked or has a broken

weld.

b. Visually check for obviously loose, damaged, or

Drawbar coupler or safety chains

missing drawbar coupler and safety chains.

loose, damaged, or missing.

7

BRAKES

a. Couple trailer to towing vehicle (para 2-8) and fully

Any signs of leakage are found.

charge airbrake system. Listen for air leaks.

b. Check brakes for proper operation. Engage brakes

Brakes fail to operate.

and attempt to pull trailer forward.

c. Check handbrakes for proper operation. Adjust

handbrake lever as required (para 3-7).

8

LIGHTS

Connect intervehicular cable and check lights for

proper operation. Check for damage to intervehicular

cable and lights.

9

LEVELING JACKS AND RETRACTABLE SUPPORT

ASSEMBLY

Check leveling jacks and retractable support assem-

Leveling jacks and retractable

bly for proper operation, secure mounting, and loose

support assembly do not operate

or missing parts.

or have loose or missing parts.

2-5