TM 9-2330-246-14

LANDING GEAR REPAIR (EARLY MODEL) (Con't).

5-5.

8.

Screw nut onto screw and check full length of

screw for ease of operation or wear. Remove nut

after inspection.

9.

Check gib and its contacting grooved surface in

lower leg for burrs and wear. Remove burrs with

fine file and finish with fine abrasive cloth.

10.

Insert lower leg in upper leg and simulate full

retraction and extension. Check for ease of

operation.

11.

Check wheels and axl for ease of operation and

alinement.

12.

Allparts found serviceable after inspection and

repair must be rust and corrosion free. Use fine file

or abrasive cloth to clean affected areas.

13.

inspect all exterior surfaces for chipped paint,

Scrape loose paint, clean and dry area, and prime

coat (TM 43-01 39).

ASSEMBLY

c.

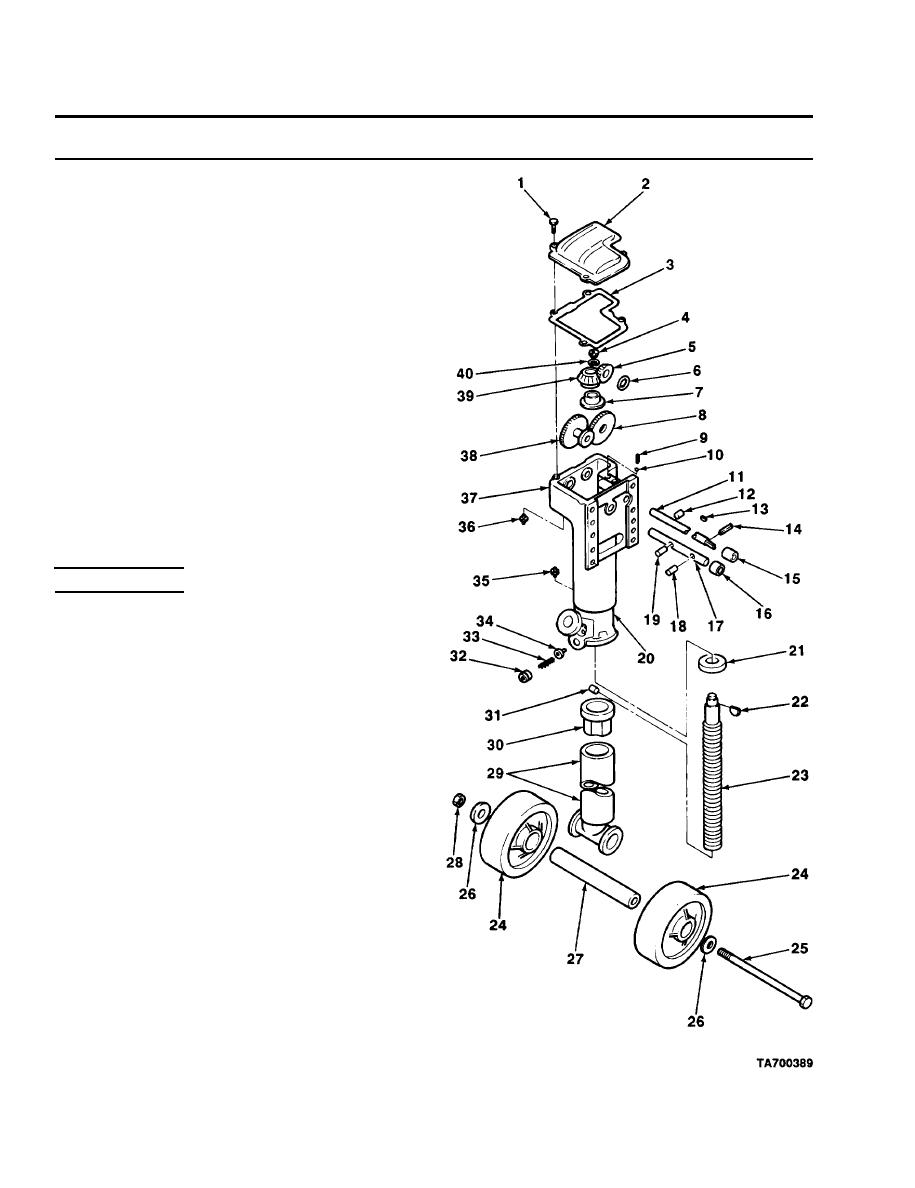

1.

if sleeve bearings (15 and 16) were removed,

Press in place using an arbor press or equivalent.

Match drll from gearbox a 27/84 in. (1 .07 cm)

diameter hole through top of new sleeve bearing

(16) to allowball bearing (10) to contact shaf t(11).

Remove burrs and loose chips.

2.

if removed, install nut (30) in lower leg (29) using

arbor press or equivalent. Ensure that holes for

pins (31) are in perfect alinement.

If removed, install two pins (31) to secure nut (30)

3.

to lower leg (29). Ensure that pins are fully seated

to prevent binding on screw (23).

4.

Lubricate screw (23) with grease. install screw in

nut (30). Engage screw about half its total length.

Lubricate roller bearing (21) with grease. install

5.

roller bearing on screw (23) and insert entire lower

leg (29) into upper leg (20) until roller bearing

contacts underside of gearbox (37).

Lubricate bevel gear (39) with grease. Assemble

6.

machine key (22), bevel gear, and retaining band

(40) to top of screw (23) and secure with new

locknut (4).

5-10