TM 9-2330-246-14

MANUFACTURING INSTRUCTIONS

(Con't)

Section

Il.

1. Binding. Cables shall be bound together with one-half overlapping turns of electrical insula-

tion tape (Item 28, Appendix E).

NOTE

Do not distort skirts of pin contacts (MS27148) when crimping to conductors.

2. Crimping. Crimp pin contacts (ferrules), terminals, and splicing connectors to cables (con-

ductors and/or insulation).

nal assemblies in accordance with TM 9-237.

4. Splicing.

a. Spliced conductors must be adequately insulated and the insulation must be sealed to each

cable's insulation.

b. Vulcanize splices using solid rubber sheet (Item 21, Appendix E). Thickness of rubber over

exposed conductors will be 1/8-5/32 in. (3.18 to 3.97 mm) and is to overlap adjacent insulation for

a distance of at least 3/16 in. (4.76 mm) and a minimum thickness of 1/32 in. (0.79 mm).

5. Plugging. Plug all spare grommet holes with rod of diameter and length as required.

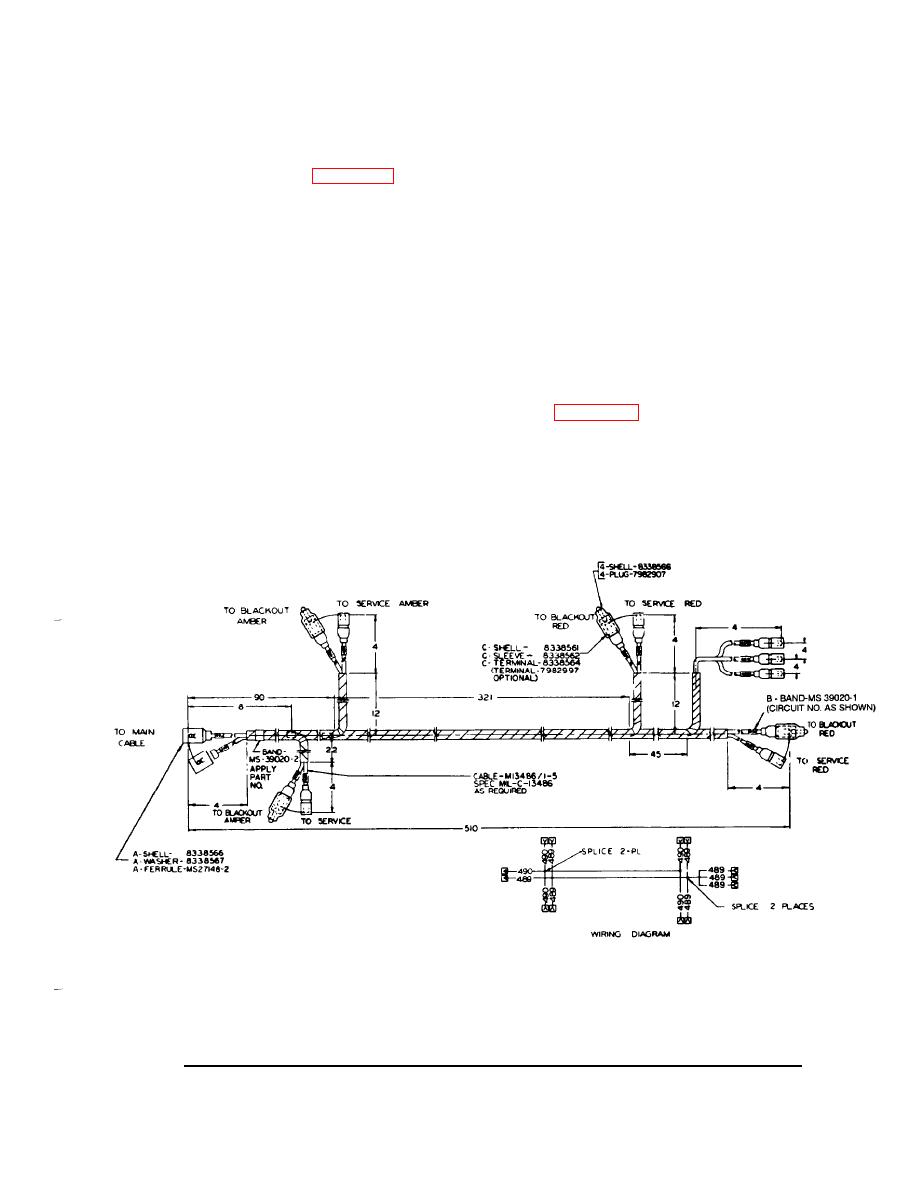

Figure F-11 Roof Wiring Harness.

TA700405

F-13