TM 9-2330-251-14&P

5-1. BRAKESHOE REPAIR (M416) (Con't).

WARNING

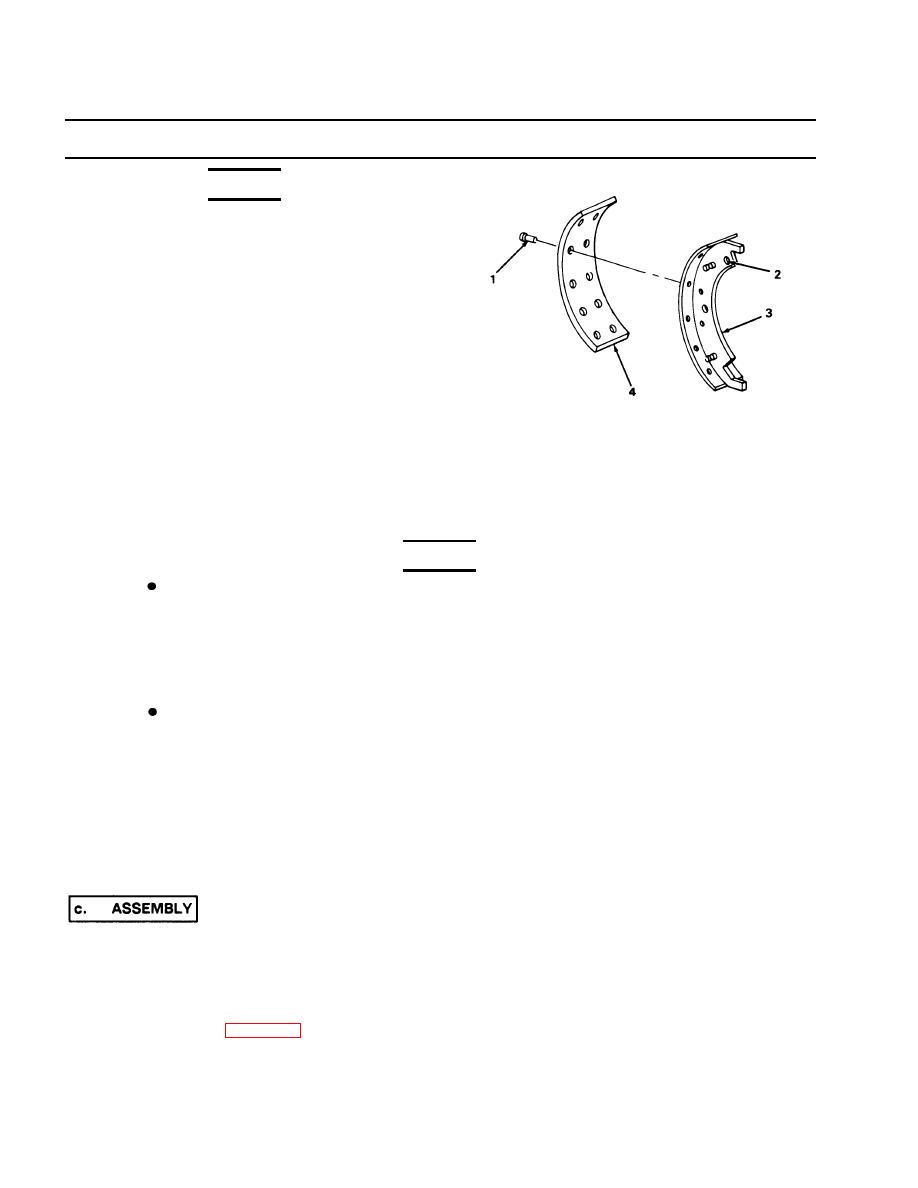

Do not grind rivet (1) heads off of brakeshoes

(3) when removing friction linings (4). Asbes-

tos dust from friction linings is hazardous to

your health.

NOTE

This procedure describes replacement of

friction linings (4) from 1 set of brakeshoes

(3). If friction linings are bonded, no repair is

authorized.

1.

Remove 10 rivets (1) and friction lining (4) from

brakeshoe (3). Discard rivets and friction lin-

ing.

2.

Repeat step 1 to remove friction lining (4) from other brakeshoe (3).

WARNING

DO NOT handle brakeshoes, brakedrums, or other brake components unless area

has been properly cleaned. There may be asbestos dust on these components

which can be dangerous if you touch it or breathe it. Wear an approved filter mask

and gloves. Never use compressed air or a dry brush to clean brake components.

Dust may be removed using an industrial-type vacuum cleaner. Clean dust or mud

away from brake components with water and a wet, soft brush or cloth. Failure to

follow this warning may result in serious illness or death to personnel.

Dry cleaning solvent P-D-680 is toxic and flammable. Always wear protective

goggles and gloves, and use only in a well-ventilated area. Avoid contact with skin,

eyes, and clothes, and DO NOT breathe vapors. DO NOT use near open flame or

excessive heat. The solvent's flash point is 100F-130F (38C-59C). If you

become dizzy while using cleaning solvent, immediately get fresh air and medical

help. If solvent contacts eyes, immediately wash your eyes and get medical aid.

1.

Clean brakeshoes with dry cleaning solvent. Dry thoroughly.

Visually check brakeshoes (3) for cracks and distortion, Discard brakeshoes if cracked or distorted.

2.

Visually check pivot holes (2) for excessive wear, Discard brakeshoes if pivot holes are excessively worn.

3.

1.

Install new friction lining (4) on brakeshoe (3) with 10 new rivets (1),

Repeat step 1 to install new friction lining (4) on other brakeshoe (3).

2.

FOLLOW-ON TASKS:

Install brakeshoes (para 4-30).

TA503968

5-2