TM 9-2330-372-14&P

(3) Welds: Look for loose or chipped paint, rust, or gaps where parts are welded together. If you find a bad

weld, report it to organizational maintenance.

(4) Electric wires and connector: Look for cracked or broken insulation, bare wires and loose or broken

connectors. Tighten loose connectors and make sure the wires are in good condition.

(5) Air hose lines: Look for wear, damage and leaks, and make sure clamps and fittings are tight. If a leak

comes from a loose fitting or connector, tighten it. If something is broken or worn out, report it to organizational

maintenance.

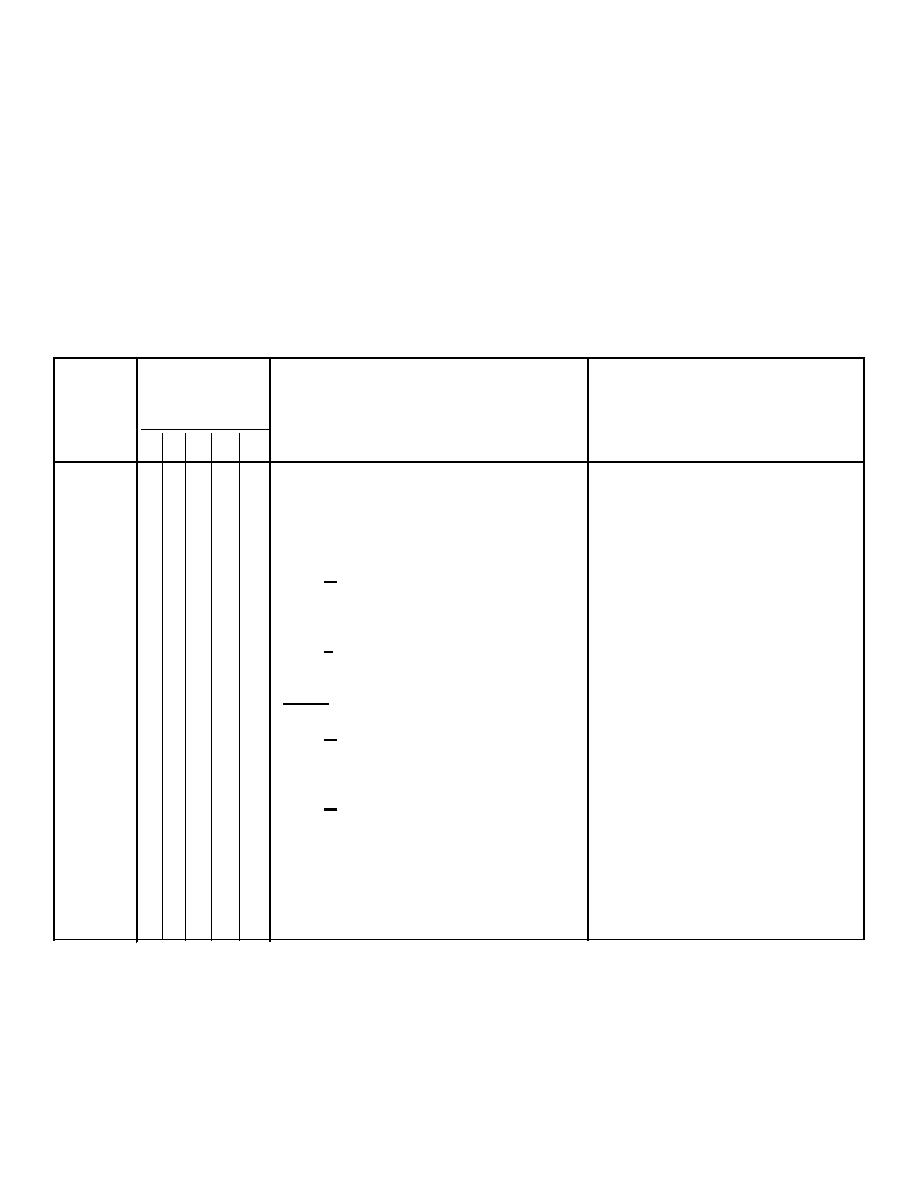

TABLE 2-1. OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B - BEFORE

D-DURING

A-AFTER

W-WEEKLY

M-MONTHLY

ITEM TO BE INSPECTED

PROCEDURE: CHECK FOR

INTERVAL

AND HAVE REPAIRED,

EQUIPMENT IS NOT

ITEM

FILLED OR ADJUSTED

READY OR AVAILABLE

NO.

BD

AWM

AS NEEDED

IF:

NOTE

Perform weekly as well as before PMCS

if:

a. You are the assigned operator but

have not used the trailer since the last

weekly check.

b. You are operating the trailer for

the first time.

1.

TIRES

a. Check tires for obviously low

One or more tires

pressure, deep cuts, foreign objects or

flat, missing or

unusual tread wear.

unserviceable

b. Check tires, including spare, for

correct pressure.

XM1034 XM1048

Highway

45 psi

75 psi

Off Road

45 psi

75 psi

2-3