TM 9-2330-381-14

c. Continually monitor fluid level in drain pan and, when drain pan is approximately full, signal person on gooseneck

to CLOSE oil valve (8). Install caps/plugs into hose.

d. Dispose of hydraulic fluid in accordance with standard shop practices.

e. Position drain pan on tool cabinet with opening in drain pan under oil valve (8).

f. Repeat steps a thru d as required until all fluid that can be drained from this hose has been drained.

9.

Remove caps/plugs installed and connect hydraulic hose (9) to straight adapter (10).

10.

The hydraulic tank has been sufficiently drained for maintenance to be performed on the system. If fluid change is

required due to contamination, proceed with step 11.

11.

Using two people to empty hydraulic tank, proceed as follows:

a. Position rolling tool cabinet under semitrailer gooseneck so that cabinet is under APU hydraulic pump.

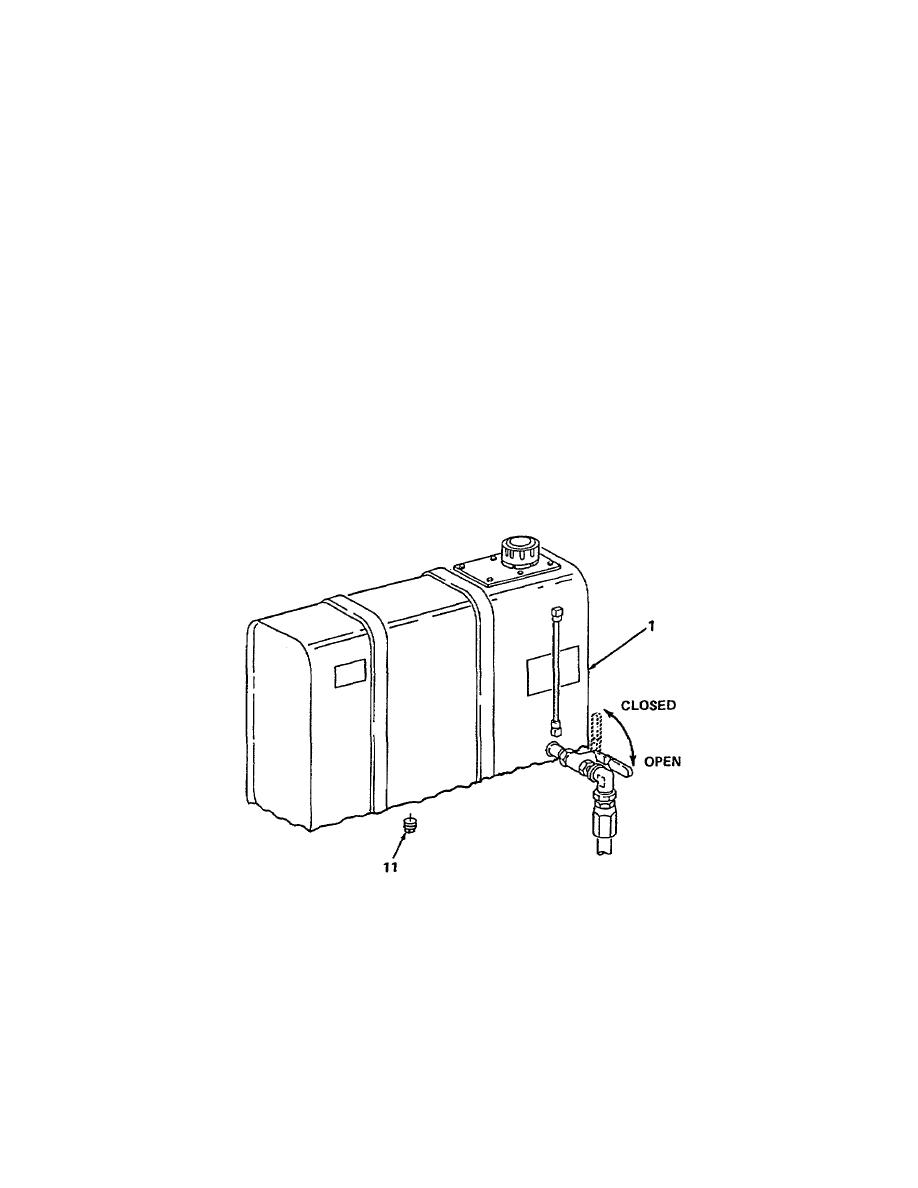

b. Position opening in drain pan centered under drain plug (11) on bottom of hydraulic tank (1), located just aft of

APU pump.

c. Move all hydraulic lines and electrical ground straps clear of fluid drain path.

d. With a person standing under gooseneck, remove drain plug (11) from bottom of hydraulic tank (1).

4-73