TM 9-2330-381-14

5-24.

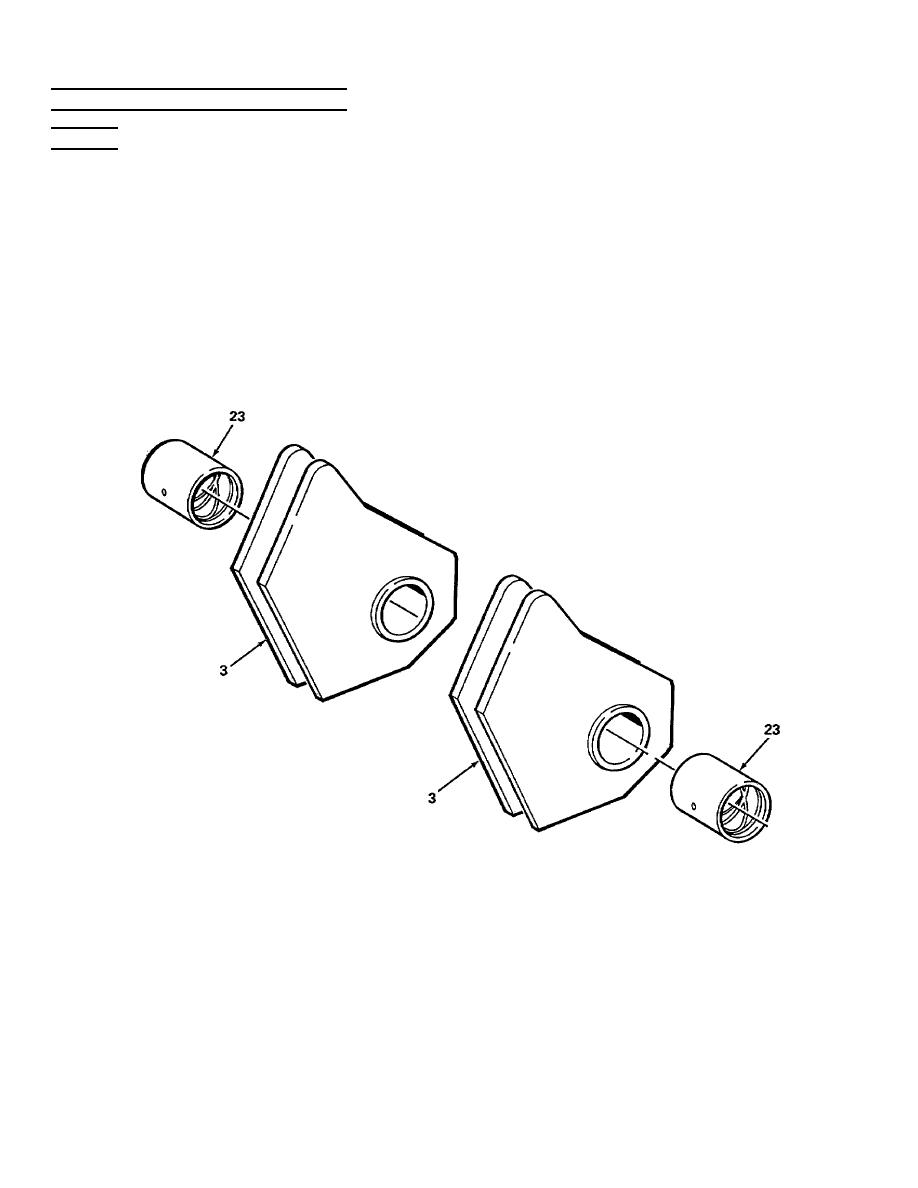

GOOSENECK/PIVOT PIN (CONT)

REPAIR

CAUTION

Do not allow hone to cut the bearing cavity surfaces or cavity may become too

large and result in premature pivot pin failure.

1.

Clean pivot pin bore using a drill motor, cylinder hone, and cutting oil. Hone pivot pin cavity to polish inside

surfaces only.

2.

If bearings are scored or slightly corroded, clean inside bearing surfaces using a power drill and cylinder hone.

Hone bearing cavity to polish inside surfaces only. If bearings are unevenly worn, pitted, or defective, replace

bearings as follows:

a. Using a hammer and brass drift, drive old bearings (23) out of bearing cavity.

b. Using a drill motor and cylinder hone, hone bearing cavity in gooseneck. Hone gooseneck bearing cavity to

polish inside surface only.

c. Aline new bearings with bore in gooseneck. Using old bearing and hammer, drive new bearings (23) into

gooseneck (3) by hammering against old bearing.

5-122