TM 9-2330-384-14&P

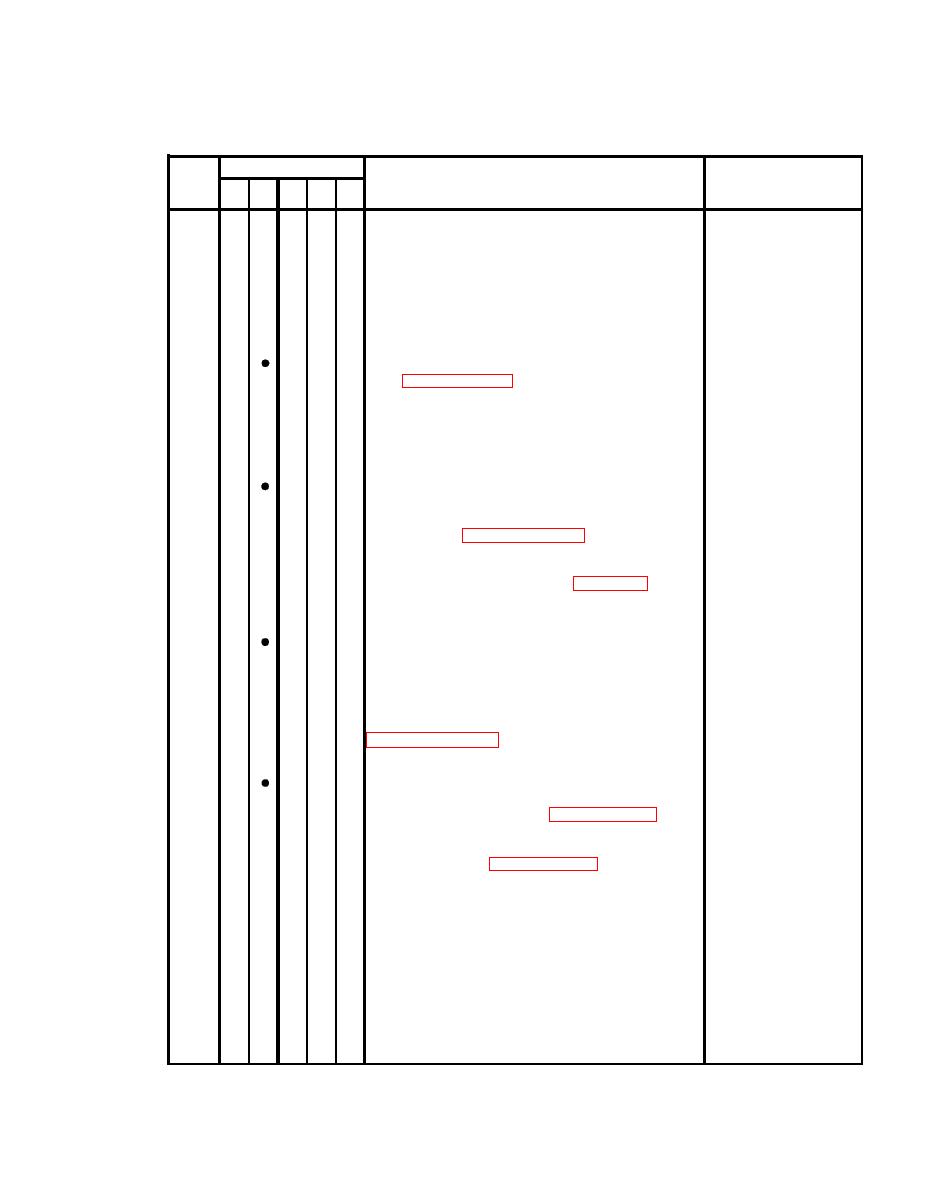

Table 2-1. Operator Preventive Maintenance Checks and Services (PMCS) (Con't).

B-Before

D-During

A-After

W-Weekly

M-Monthly

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS

ITEM

PROCEDURE: Check for and have Repaired, Filled, or

NOT READY/

NO.

B

D

A

W

M Adjusted as required.

AVAILABLE IF:

OPERATIONAL CHECKS (Con't)

8

NOTE

If

semitrailer

parking/emergency

brakes have already been set, brake

interlock system will not operate. This

is normal.

k. Check operation of brake interlock system Brake interlock sys-

(see paragraph 1-13). While loading or unload- tern malfunctions.

ing fuel, check that semitrailer parking/emer-

gency brakes automatically set when loading/

transfer hose is connected to piping assembly

front port or rear inlet. Listen for a brief exhaust-

ing of air under semitrailer.

I. While bottom loading fuel, open precheck

ANY FUEL LEAKS.

valve to activate the precheck cycle. Once

emergency valve has closed, resume bottom

loading (see paragraph 2-19). If emergency

valve does not close within two minutes, or if

bottom loading does not resume, refer to

troubleshooting instructions in Chapter 3. Report

any leakage in precheck system to unit

maintenance IMMEDIATELY.

m. While loading or unloading fuel, check for

ANY FUEL LEAKS.

fuel leaks at emergency valve, piping assembly,

front port, rear inlet, nozzles, and transfer

hoses. When bottom loading, check for leaks in

precheck tubing and around fittings at pressure

gage and precheck valve inside cabinet (see

paragraph 1-15). R e p o r t a n y l e a k a g e o r

malfunction to unit maintenance IMMEDIATELY.

n. While unloading fuel, pull on emergency ANY FUEL LEAKS

valve control lever to close emergency valve BE- E m e r g e n c y v a l v e

FORE tank is empty (see paragraph 2-2). Fuel malfunctions.

flow should stop after piping is drained. Check to

see if fuel continues to flow from butterfly valve

at front port (see paragraph 2-2). If fuel contin-

ues to flow, emergency valve is malfunctioning.

Report any leakage or malfunction to unit main-

tenance IMMEDIATELY.

2-25