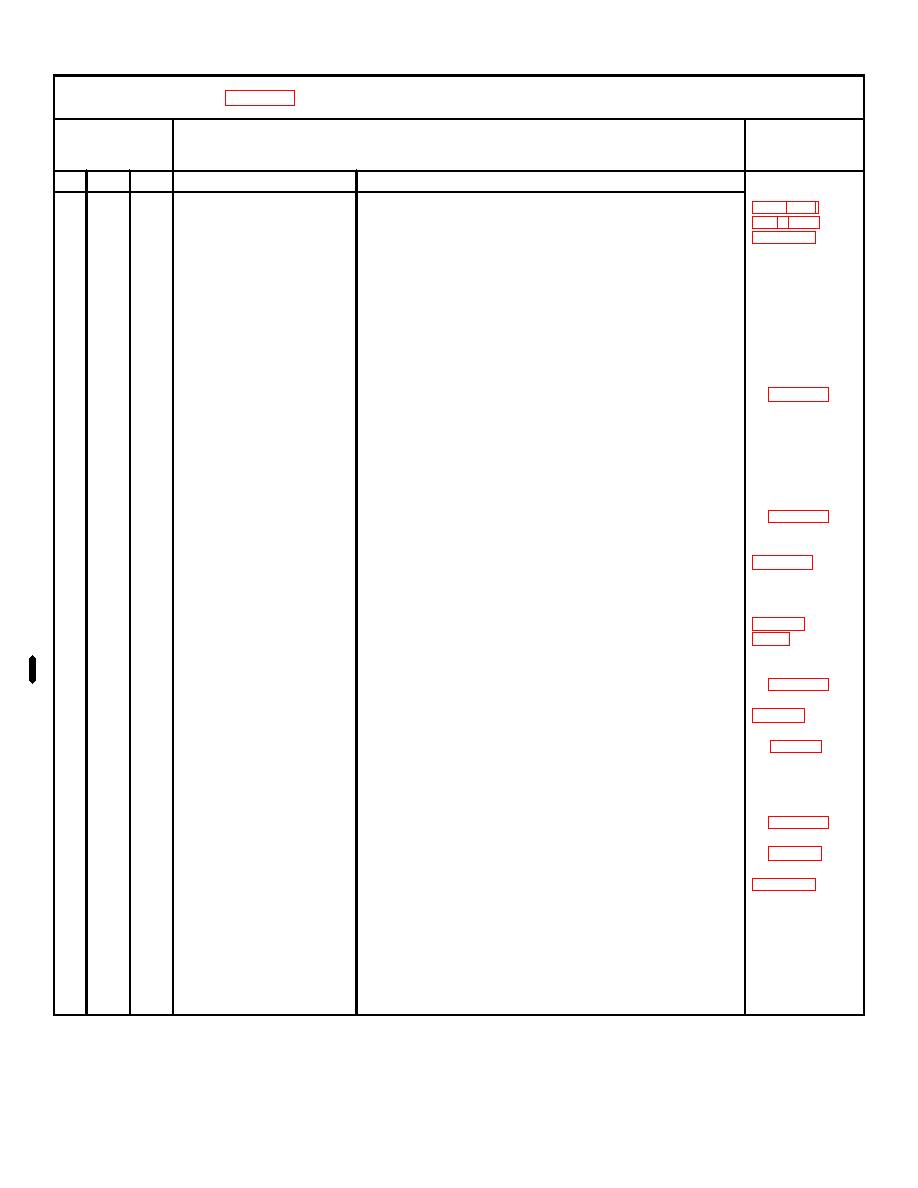

TM 9-2350-230-12, C6

INTERVAL AND

SEQUENCE

B - BEFORE OPERATION D - DURING OPERATION A - AFTER OPERATION

REFERENCE

B

D

A

ITEM TO BE INSPECTED

PROCEDURE

30

108

Traverse Mechanism

Rotate full 360 degrees manually to determine that ring

gear is free and backlash is not excessive. Power

traverse cupola 360 degrees in each direction with

traverse mechanism switch assembly buttons on machine

gun spade grips and rotation switch on cupola control

assembly. Cupola should not coast after release of

buttons or rotation switch.

TURRET (INTERIOR)

NOTE Check selector knob setscrews.

31

109

Loader's Hatch

Check seal and crash pad for damage or deterioration

D, Fig. 2-20

Cover

Hatch cover must lock securely in open and closed

positions.

32

Turret Seats and

Check for ease of operation and adjustment Inspect

A, C, F, Fig.

Pads

cushions and pads for secure mounting and serviceable

2-20

condition.

33

110

Turret Traverse

Check for effective operation

C, Fig. 2-20

Lock

34

Ammo Racks and

Check pin safety clips securing vertical ammo rack and

Protective

screens to turret ring to be sure they are installed.

Screens

35

111

Ammo Racks

Check ammo arms and catches for shell holding tension

Fig. 3-3 and

Determine if shell pads are present and properly

installed.

112

Stowage Boxes

Clean miscellaneous boxes of corrosion and debris

C, Fig. 2-20

35.1 67.1

112.1

Floor Access

Clean debris from under turret floor as necessary

36

Fuel Tank(Center)

Drain condensation

A, Fig. 5-3

37

113

Interior Basic-

Check condition and stowage.

Issue-Items

38

114

Turret Ventilating Fan

Check operation

E, Fig. 2-20

39

115

Dome Lights

Check operation. Replace lamps if defective

D, Fig. 2-6

40

116

Turret Traverse

With vehicle on level ground, traverse turret full 360

Mechanism

degrees manually and with power. Effort required to

manually traverse should be uniform and must not

have over 1-1/2 mils of backlash. If manual control shaft

binds, coat with PL.

4-6