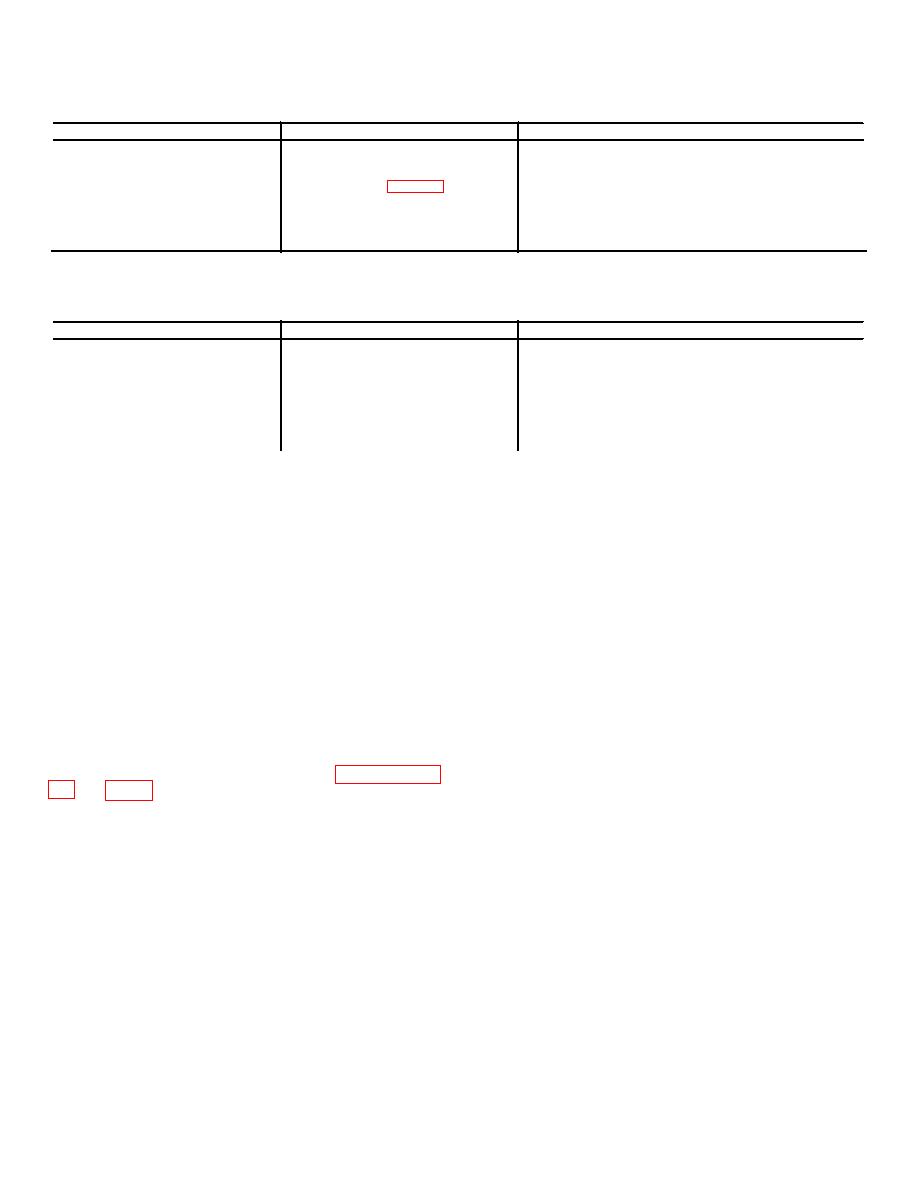

Table 4-6. Troubleshooting Electromagnetic Clutch Assembly

(Power Take-off Group)

Malfunction

Probable cause

Corrective action

Electro Magnetic Clutch Assembly

a)

Defective power

Repair/replace defective power

inoperative

takeoff transmission

take-off assembly.

assembly (see table 3-6),

b)

Defective sprocket

Repair/ replace defective sprocket

assembly.

assembly.

c)

Defective sprocket

Replace defective sprocket ring

ring assembly.

ring assembly.

Table 4-7. Troubleshooting Power Take-Off Transmission Assembly

Malfunction

Probable cause

Corrective action

Power Take-Off Transmission

a)

Power take-off

Repair/ replace defective right

Assembly inoperative

right drive assembly

drive assembly.

defective.

b)

Hydraulic pump

Repair/ replace defective hydraulic

assembly defective.

pump assembly.

c)

Magnetic clutch

Repair/replace defective clutch

defective.

assembly.

Section V. General Maintenance Instructions

repair or rebuild operations, apply a light grade of

4-19. General.

preservative oil to all polished metal surfaces to prevent

4-20. This section provides general maintenance

rusting.

instructions for direct support, general support and depot

(a) Dip-tank. Disassemble as required,

maintenance personnel to maintain and various

place parts in a perforated metal basket, and submerge

bulldozer components.

and agitate parts in a tank containing dry-cleaning

4-21. Cleaning.

solvent or mineral spirits paint thinner. Repeat, using a

4-22. All component pan of the various assemblies

second tank containing clean solvent or paint thinner.

must be cleaned after disassembly. Make certain the

Extent of treatment in each tank will depend on time

work bench is free d foreign matter. Place a large piece

needed to dissolve dirt, oil, and grease.

of heavy wrapping paper on the work bench to insure

(b) Vapor-degreaser. Tanks containing a

cleanliness. This precaution will protect the highly

heated solution of trichloroethylene or perchlorothylene

finished surfaces and reduce the danger of misplacing

(type 11) are used mostly for degreasing items that are

small parts. During disassembly and assembly avoid

very greasy or oily and are not readily cleaned by the

striking highly finished surfaces together.

General

dip-tank method. Place parts in a perforated metal b-'et

inspection and cleaning instructions for operator and

and submerge just below the vapors in the tank and

organizational personnel are contained in paragraphs 3-

keep there until all the grease or oil melts and runs off

the parts

depot maintenance observe the following cleaning

Warning: Personnel operating vapor-degreasers

procedures.

are cautioned not to inhale the vapor fumes.

a. Mechanical Parts.

(1) Cleaning methods. Material received

in Ordnance shops from storage will be cleaned by one

of the following methods, whichever is applicable and

available. If some time is to elapse before the start of

4-5