TM 9-3405-213-14&P

TABLE OF SPECIFICATIONS

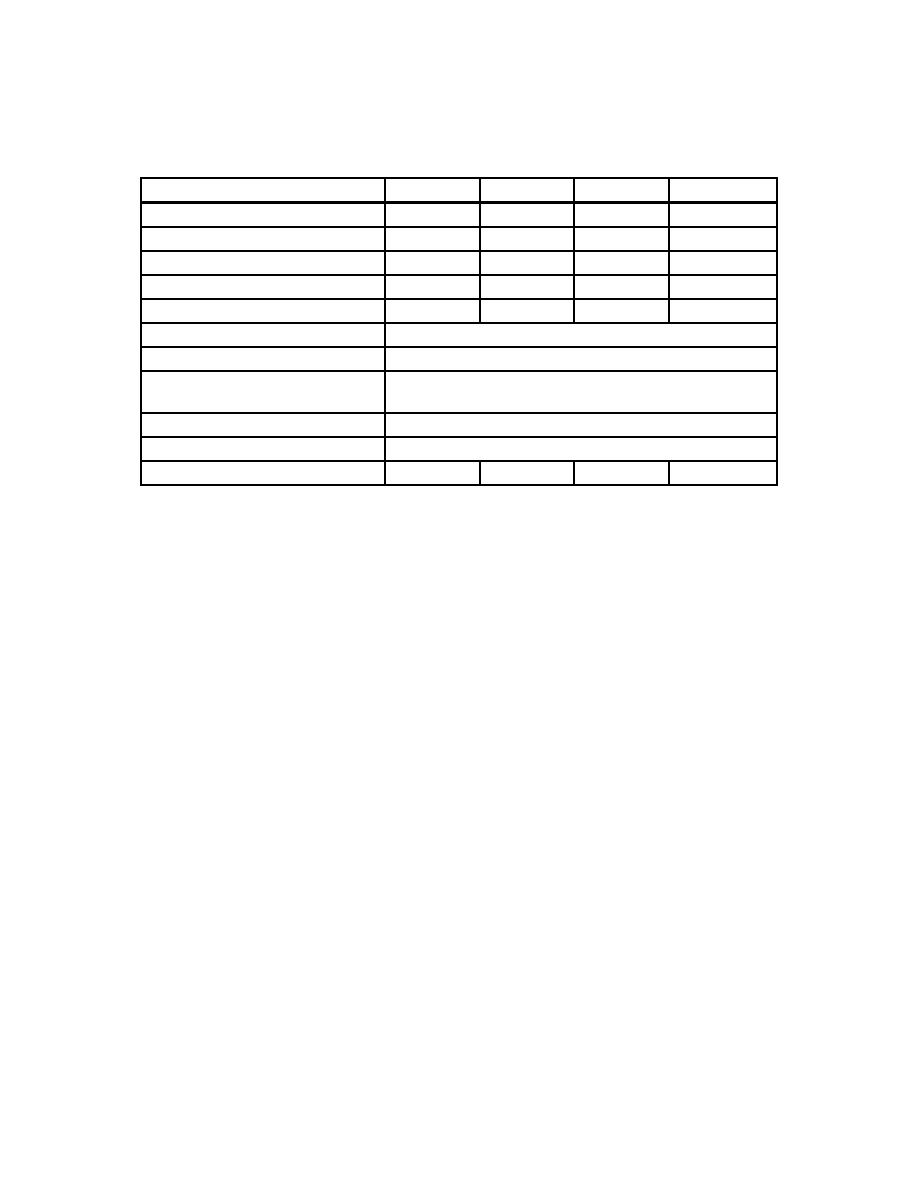

Models 1010, 1212, 1216, 1415

Heavy Duty Hydraulic Saw

MACHINE MODEL NUMBER

1010

1212

1216

1415

Rated Capacity

10" x 10"

12" x 12"

12" x 16"

14" x 15"

Actual Capacity

10" x 10"

12" x 12"

12" x 16"

14" x 15"

Capacity with Swivel

10" x 6Y"

12" x 7"

12" x 9"

14" x 9"

Vise at 45x

Blade Length

18"

21" & 18"

24" & 21"

24" & 21"

Length of Stroke

6"

Strokes Per Minute

150-110-85-80-60 & 45

Motor H P (Standard

5

1200 R P M)

Height, Floor to Table Top

32"

Floor Space

48" x 84"

Shipping Weight

3600

3750

3800

3850

BASE:

Heavy fabricated cabinet under rear of machine, fabricated base supporting front end.

SAW GUIDE:

Rigid one-piece construction pivoted 10" back of crank shaft. Double slide bearings on top and

on both sides of frame. Adjustable gib on one side, two adjustable bottom gibs.

SAW FRAME:

Heavy cost iron construction. Side bearing plates 1-1/8" thick, 3" wide, are bolted through frame

and accurately ground. Felt pad lubrication bearing plates cannot distort from heavy blade

tension.

GEARED HEAD:

Built in as integral part of the machine. Gears all steel and hardened. Cluster gears mounted on

6-spline shaft. Drive from 3-speed gears is through internal bull gear mounted on crank shaft.

Six-speeds obtained by 2 step Poly Vee Belt Drive.

FEED:

Two types of feed are available on all machines flexible (constant pressure feed) and positive

feed. Low pressure hydraulic system pressure obtained through simple constant volume pump

that applies pressure to top of main cylinder. Single plunger metering pump, with variable stroke

and with graduated dial adjustment regulates exact amount of feed desired throughout each

cutting stroke. Graduations from 0-22 permit sensitive and accurate control of feed.

2