TM 9-3405-215-14&P

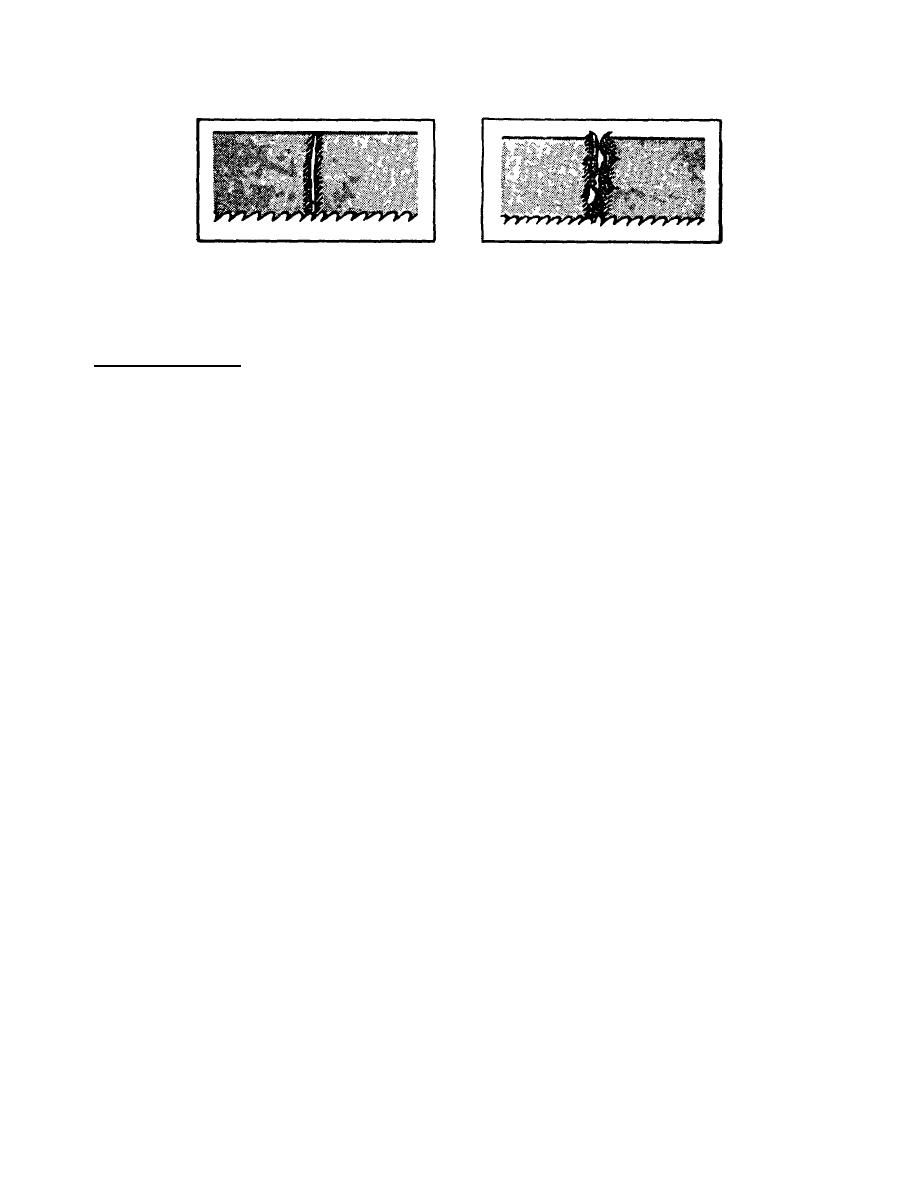

Incomplete weld.

"Blown-out" weld.

INCOMPLETE WELD (joint is not complete, "blow holes" in joint)

(1)

Incorrect Initial Set-Up:

(a) Initial jaw gap (weld lever position) not set correctly.

(b) Upset force control not set correctly.

(2)

Improper clamping procedures.

(3)

Defective cut-off switch may not break the circuit at end of welding operation.

(4)

Cut-off switch not adjusted correctly.

(5)

Points of cut-off switch welded together.

(6)

Slide rod sticking because of rust or dirt. Clean and oil rod see Maintenance.

(7)

Slide rod movement obstructed because stop screw too tight on rod.

(8)

Jaw movement obstructed by kinked jaw cable or tangled wires. Bend cable and untangle wires.

(9)

Movable jaw binding on jaw bearings because of tilt adjustment screw turned in too far.

BRITTLE WELDS

(1)

Weld has not been annealed correctly, see "Annealing" in Operation Chapter. Poor annealing can be caused by:

a.

Incorrect annealing heat. Bring weld up to correct color as described under "Annealing" in Operation Chapter.

b.

Scale or oil on weld can cause poor annealing.

123