TM 9-3405-217-14&P

HOW TO SELECT AND USE POWER HACK SAW BLADES

Power hack saws automatically take a Full Stroke

for a better bite, without clogging. (OF course, the fee-

each time, automatically Lift the blade on reverse stroke

per tooth must be kept below the point of fracturing the

and apply steady cutting pressure throughout the length

teeth).

of the stroke

Large Sections and soft materials require coarse

The proper tensioning of the power hack saw blade is

teeth. Thin sections and hard-to-machine materials

most important. Insufficiently tensioned blades wear

require fine teeth.

rapidly, cut inaccurately and deliver a blank with a poor

finish. A blade tensioned too tightly breaks prematurely

USE HEAVY FEED PRESSURE

or pulls out at the pin hole.

Normally you should set the feed pressure as heavy

as possible without breaking the teeth or making the

blade cut crooked. Excessive pressure and stroke

speed increase the cutting rate at the expense of blade

wear. (When in doubt, keep pressure at maximum but

reduce the stroke speed

The heaviest practical pressure . . . and the fastest

reasonable stroke speed produce the most efficient

cutting

A feed-rate that is too light results in rubbing instead

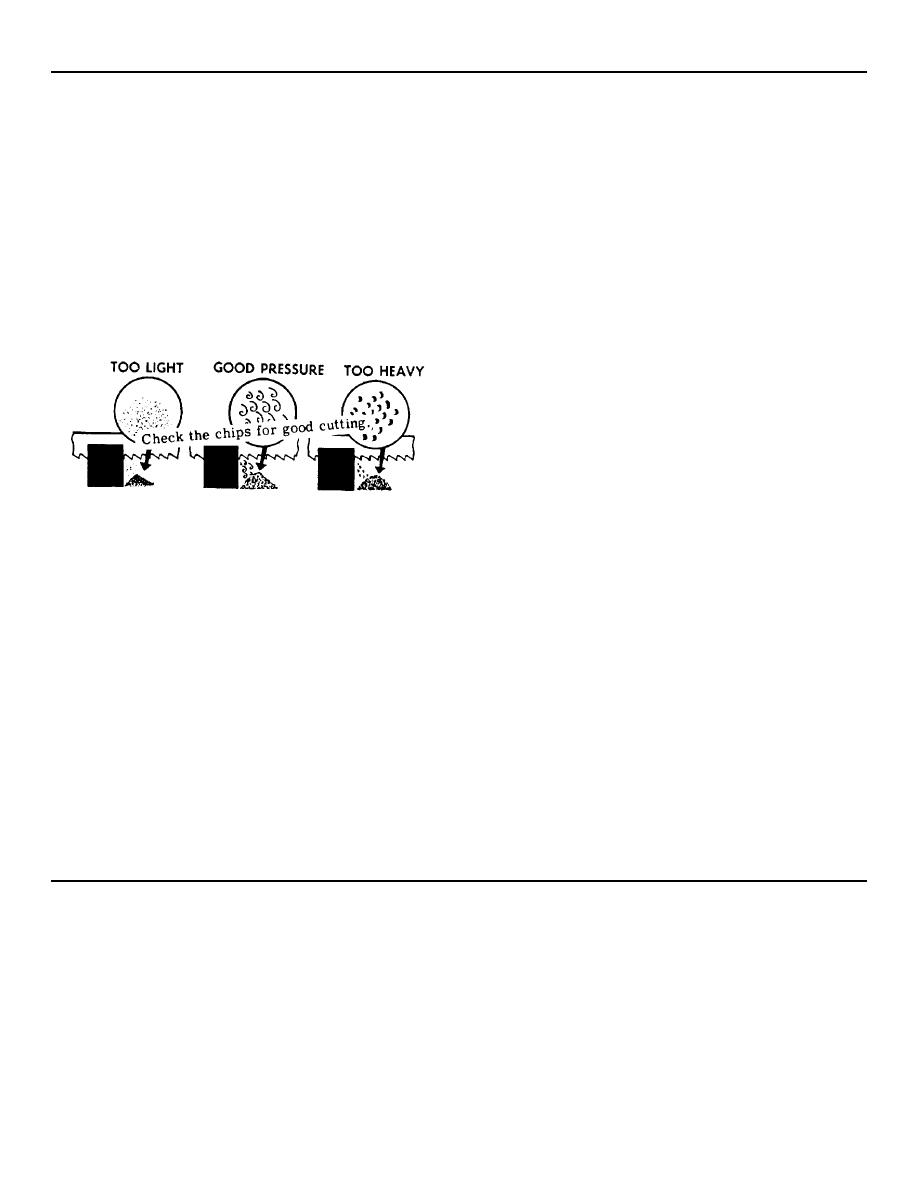

If chips are burned you are feeding too heavy. If

of cutting; (tooth point overheat, soften and break down).

chips are fine and powedery you are feeding too light. A

free cut with nicely curley chips indicate ideal feeding

For optimum feed rate: Use heavy feed for hard, very

pressure, fastest cutting time and longer life.

dense material ---light feed for thin soft material. For

maximum production, you can increase feed by using

For most cutting jobs, the all-hard blade is first choice

coarse blades on soft materials. But remember to use

for straight, accurate cutting. The all-hard tungsten

moderate feed when straight, accurate cutting is

blade is unexcelled for retaining its sharp teeth. It

required.

handles work hardering materials, abrasive material,

stainless, high manganese steel and the low

USE PLENTY OF COOLANT

machinability bronzes. Molybdenum blades are good for

fast accurate cutting, but especially on low or medium

Start the coolant flow before the first cutting stroke.

alloy steels, iron and most non-ferrous metals.

Coolant is needed on materials (except cast iron, copper

and some brasses) to reduce friction, blade wear, and

You gain more by selecting the COARSEST TOOTH

chip clogging. Keep coolant flowing until job is finished

for the work. The is necessary for good chip appearance

and the blade is stopped. For best blade life and fastest

as more pressure can be applied

cutting time use TRIM EP, a product of Master Chemical

Corporation.

3