PARTS LIST

TO MOUNT AND ADJUST 9" & 10K END GEAR GUARD

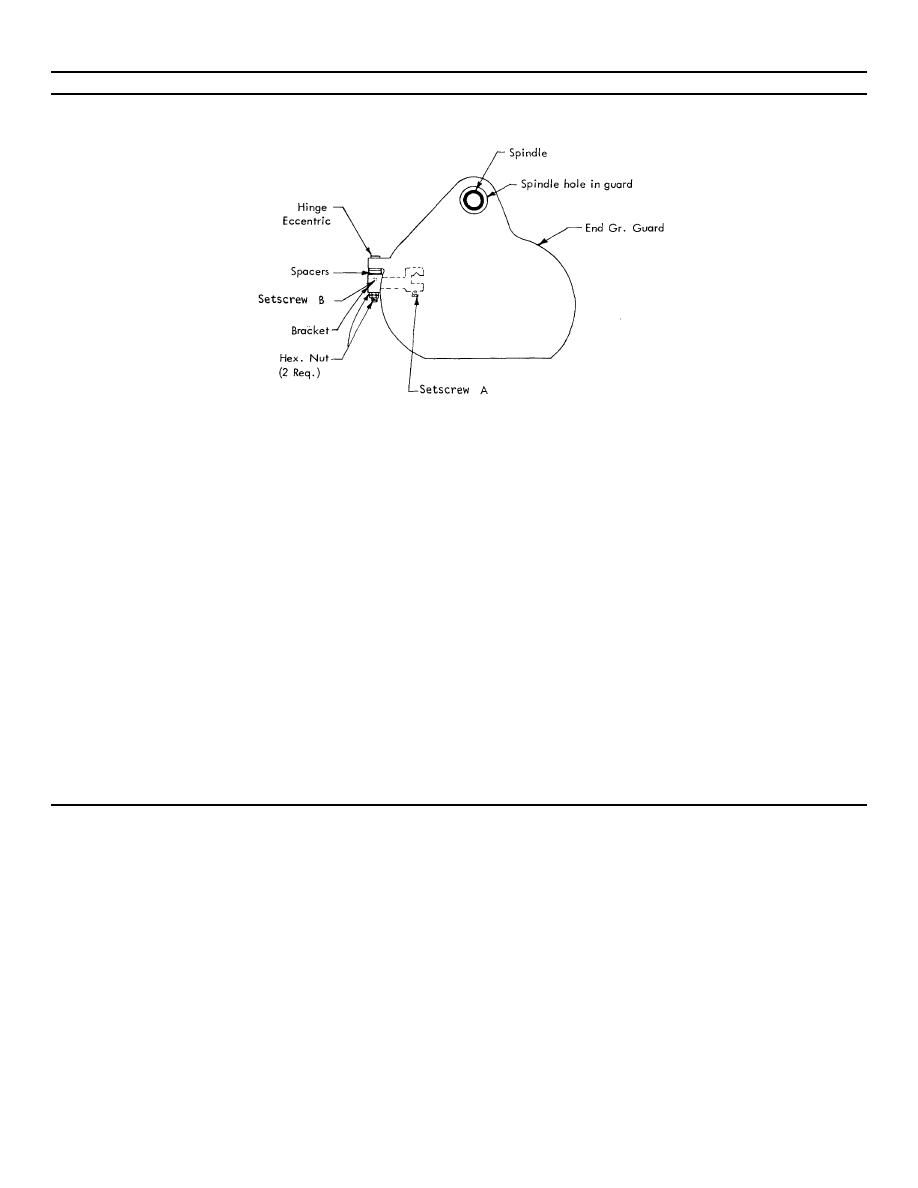

1. Install bracket on bed and secure in place. On horizontal lathes set bracket near end of bed. On underdrive

lathes set bracket approximately 1/4" back from end of bed. Tighten setscrew A

2. Place eccentric in guard and mount in bracket with spacers between guard and bracket. (See fig. above) Use

any combination of spacers required for proper clearance between spindle end and hole in guard.

NOTE: Spacers of varied thicknesses are supplied for the purpose of using any combination to

obtain proper installation.

3. Install one hex nut on end of hinge eccentric just enough to allow the second one to be installed.

4. Install second hex nut and lock with first.

5. Adjust the guard right or left by turning the eccentric by the locked nuts with a wrench.

6. Secure eccentric by tightening setscrew B

7. Unlock nuts and turn one up against bracket tight enough to keep guard closed but loose enough to swing open

by hand.

8. Lock with second nut.

NOTE: New machines have hinges tightened to keep guard closed during transit.

It may be

necessary to loosen hex nuts slightly and relock to allow guard to open easier.

13