TM 9-3418-201-14 & P

CLEANING

Before shipment, all unpainted surfaces were coated with a rust preventive compound. This may be removed by

wiping with rags saturated with a nonflammable cleaning fluid. Clean only by wiping and brushing. Do not use

compressed air as this tends only to force dirt and grit into the working parts.

After the slushing compound has been removed, wipe all finished surfaces with a cloth moistened with lubricating

oil. Do not move any of the controls or moving parts until the machine has been thoroughly cleaned and lubricated.

INSTALLATION

The first consideration in maintaining the accuracy of any machine tool is to see that it is supported by a rigid

foundation. For a machine of this size a concrete floor furnishes sufficient foundation. Anchor bolts should be embedded

in the concrete.

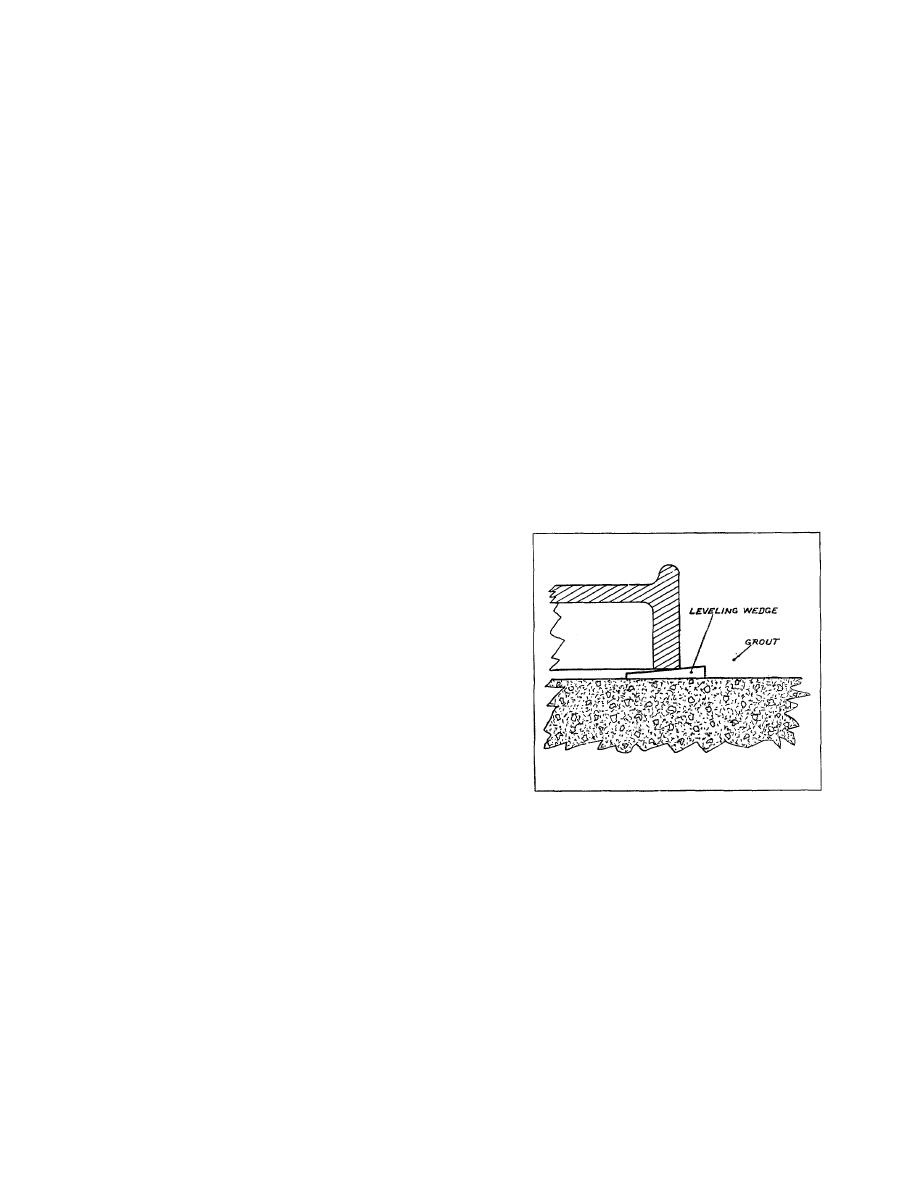

Holes for six anchor bolts are provided in the base plate, one pair near the front end, one pair at the front corner of

the column, and one pair at the rear corner. Level the machine by using steel wedges ,under the base plate near the

anchor bolts at the four corners of the column, leaving the front end of the base plate free. For crosswise leveling use the

finished top of the cross rail. For lengthwise leveling use the finished top of the column along the ram ways. Use a

precision machine level. A carpenter's or mason's level is not sufficiently accurate for this purpose. When the machine

has been leveled from these four points, tighten the nuts on those four anchor bolts. Then, with the leveling screws at the

front of the base plate make adjustment until the plate on which the outer table support slides is exactly parallel to the

cross rail and tighten the screws on the two front anchor bolts.

With a rich mixture of portland cement and clean building sand and enough water to make a thick mixture (grout)

fill the space between the base plate and the floor using sufficient grout around the outside to embed the base plate to a

depth of one inch or more. Allow sufficient time for the grout to harden before starting the machine. On a machine having

a plain table the entire base plate may be embedded in grout as shown.

The universal table requires clearance so that

the outer table support may be lowered to the bottom

surface of the base plate. Therefore the space across

the front end of the base plate should be filled with grout

only up to the bottom surface of the plate.

The floor plan on the following page is typical of

the area and shape of the space required. For actual

installation use only the certified print which is mailed

prior to shipment of the machine.

If a concrete foundation is to be built,

consideration should be given as to whether or not

conduit for electric wiring is to be embedded. The floor

plan shows the location of the entrance of electric wires.

2