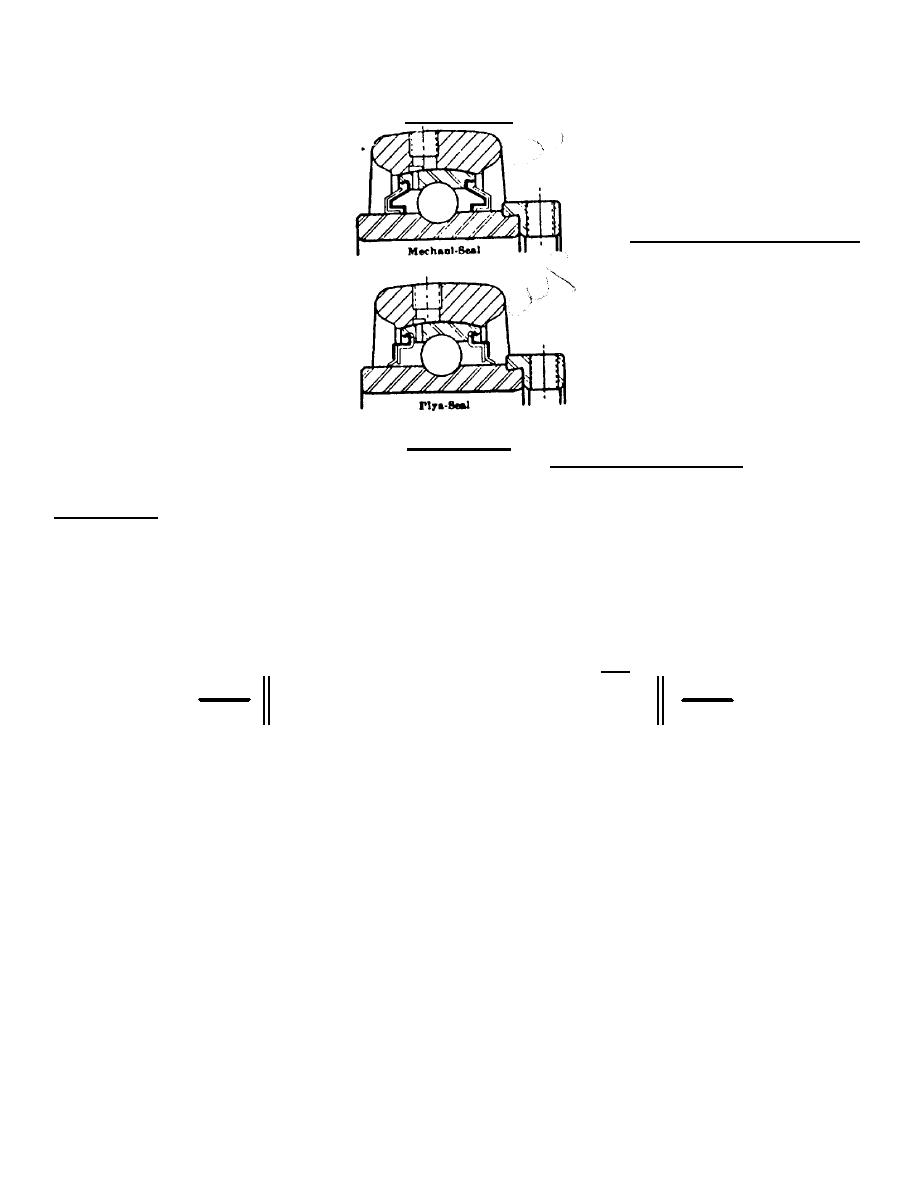

PRELUBRICATED MECHANI-SEAL AND PLYA-SEAL

TRANSMISSION UNITS

INSTALLATION

2. Slide collar against

NOTE: Shaft should be free from

cam end of inner ring. Engage

burn. If old shaft is used, be sure

cams by rotating collar until it

ball bearing is not seated on worn

slides over cammed end of inner

section.

ring. Lock collar by tapping lightly

in direction of shaft rotation.

1. Locate

assembled

Tighten

set

screw.

To

unit in position, and line up shaft

disassemble, loosen set screw and

carefully.

Self-alining units will

tap collar in direction opposite shaft

automatically

compensate

for

rotation.

misalinement, but shaft must be

straight.

Bolt unit securely to

NOTE: After installation of this

supporting structure.

unit and determination of correct

rotation,

check

for

proper

engagement of collar and tightness

of set screw.

LUBRICATION

Bearings have been factory prelubricated with high quality grease and for Normal conditions of Service require no further

lubrication.

Normal Service is considered as operation in a clean, dry, atmosphere at temperatures between -20F and 180F and at

shaft surface speeds up to 2100 ft. per minute. This corresponds to a 1" shaft at 8000 RI'M, a 2" shaft at 4000 RPM or a

3" shaft at 2700 RPM.

Where service is Abnormal with respect to speed, temperature, exposure to moisture, dirt or corrosive chemicals, or

where extremely long life is required, periodic relubrication may be advisable. To relubricate remove pipe plug and replace

with a standard 1/8 pipe thread grease fitting. The Bearing Company will advise of suitable greases for abnormal service

on request.

For bearing replacements, order by number on seal

(not on inner or outer ring).

33