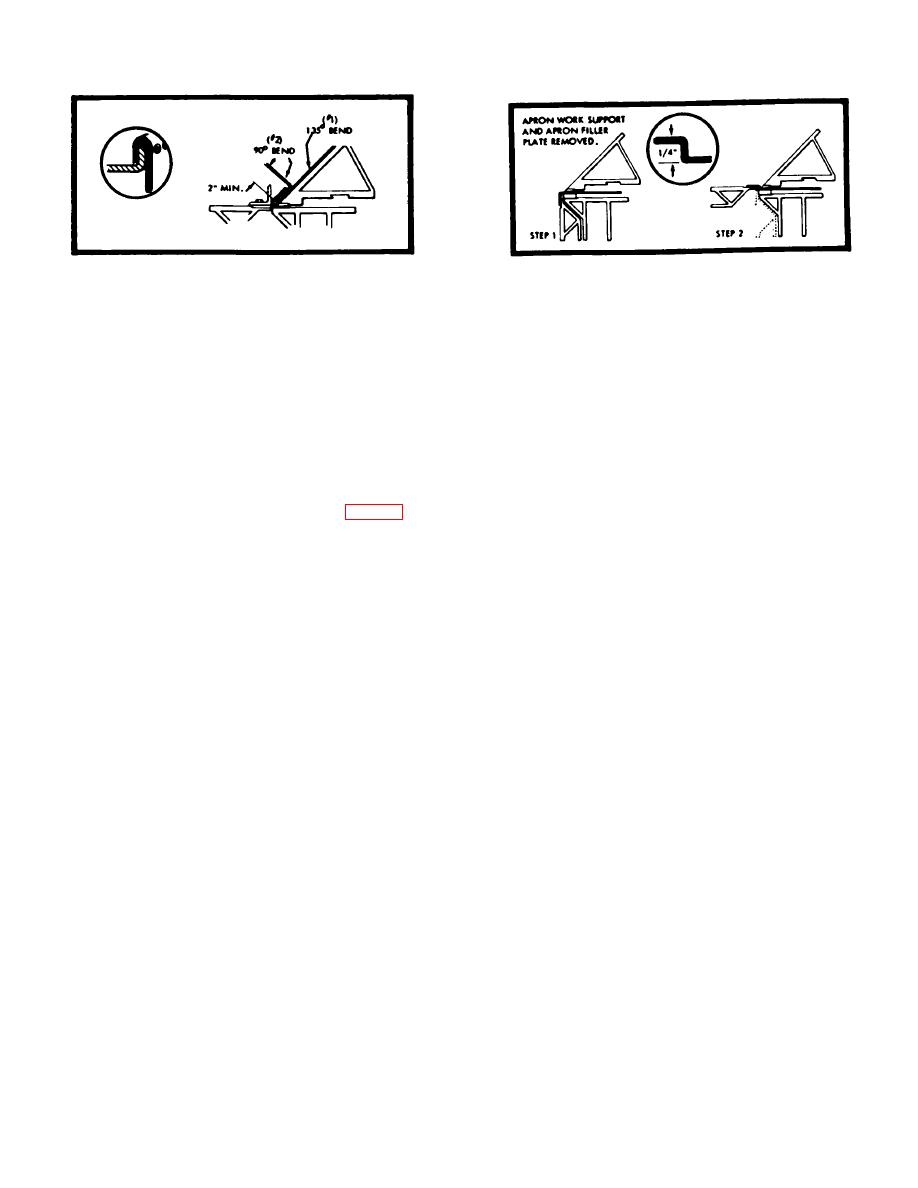

Figure 6. Jointing Two Metal Pieces

Figure 7. Minimum Reverse Bending

3 FT.--14 GA. FINGER BRAKE

CARE: Occasional oiling of moving parts with machine oil will ease operation and extend the life of the Brake. These

points include the Apron -Bearings, the Upper Beam Clamping Bearings, and Adjusting Screws.

CAUTION: Do not form wire, nails, rods or pipe in these brakes. These brakes will form a 1"

flange over the entire length in their rated capacity. Brakes are reduced in capacity by 2 gauges

when:

Apron angle iron work support ( see figure 1 ) is removed.

Brakes are reduced in capacity by 4 gauges when:

1. Apron angle iron work support and apron filler plate are removed.

2. Brake is used on stainless steel.

ADJUSTMENTS-BEFORE OPERATION

1. Apron must be flush with lower beam Jaw before beginning operation. To adjust, loosen apron mounting bolts

slightly and turn apron adjusting screws as necessary. After adjustment, retighten apron mounting bolts. If alignment

cannot be achieved, follow major brake alignment procedure below.

CLAMPING PRESSURE ADJUSTMENT

2. Check gauge of material to be formed to be sure it is within rated capacity of your brake. Place small sample of

work piece on Lower Beam Jaw and clamp in position by moving the Clamping Lever forward.

-3-