TM 9-4120-401-14

Unit Preventive Maintenance Checks and Services (PMCS)

Table 4-1.

Quarterly Schedule - continued

Paragraph

Procedures

Item to be

Item

Reference

Inspected/Serviced

Number

To avoid injury, compressed air used for

cleaning purposes must not exceed 30 psi

(2.1 kg/cm2).

4-49

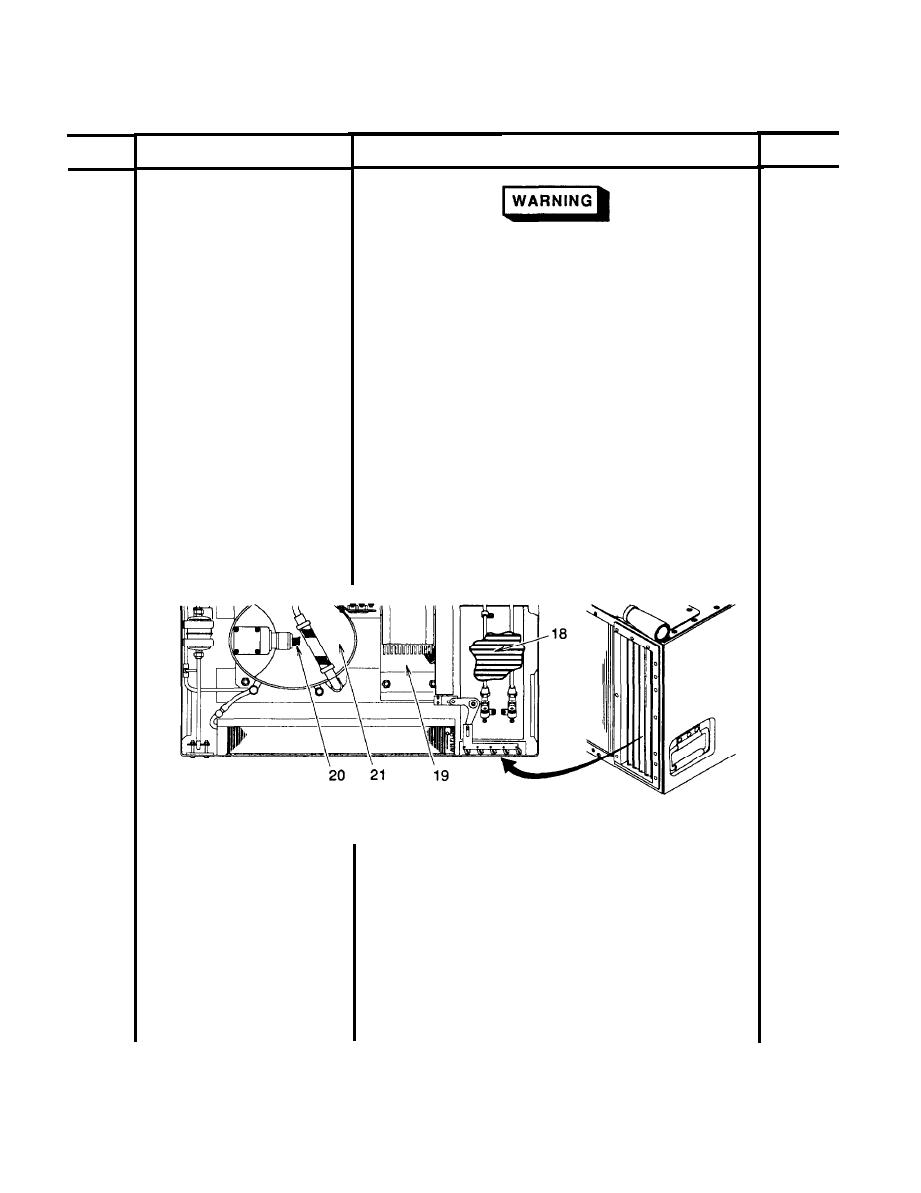

a. Blow accumulated dust and dirt out of air passages in

Condenser Coil

13

condenser coil (17) using compressed air. Blow from

inside for reverse airflow direction.

b. Inspect coil (17) for obvious damage and all mounting

hardware for tightness and security. Straighten any bent

fins.

4-46

a. Wipe dust and dirt from fan (18) and motor (19) and all

Condenser Fan and Motor

14

other components and surfaces in the area.

b. Inspect fan (18) for damage or bent blades, motor (19) for

signs of overheating, and all mounting hardware for

tightness and security.

c. Inspect wiring harness (20) for damage or chafing and all

electrical connections for tightness.

a. Wipe dust or dirt from the compressor (21) canister and

15

Compressor

remaining components and surfaces in the lower section

of the cabinet.

b. lnspect compressor crankcase heater element for signs

of overheating or deterioration.

c. Inspect wiring harness for damage or chafing and all

electrical connections for tightness.

d. Check all mounting hardware for damage or chafing.

4-22