TM 9-4520-260-13

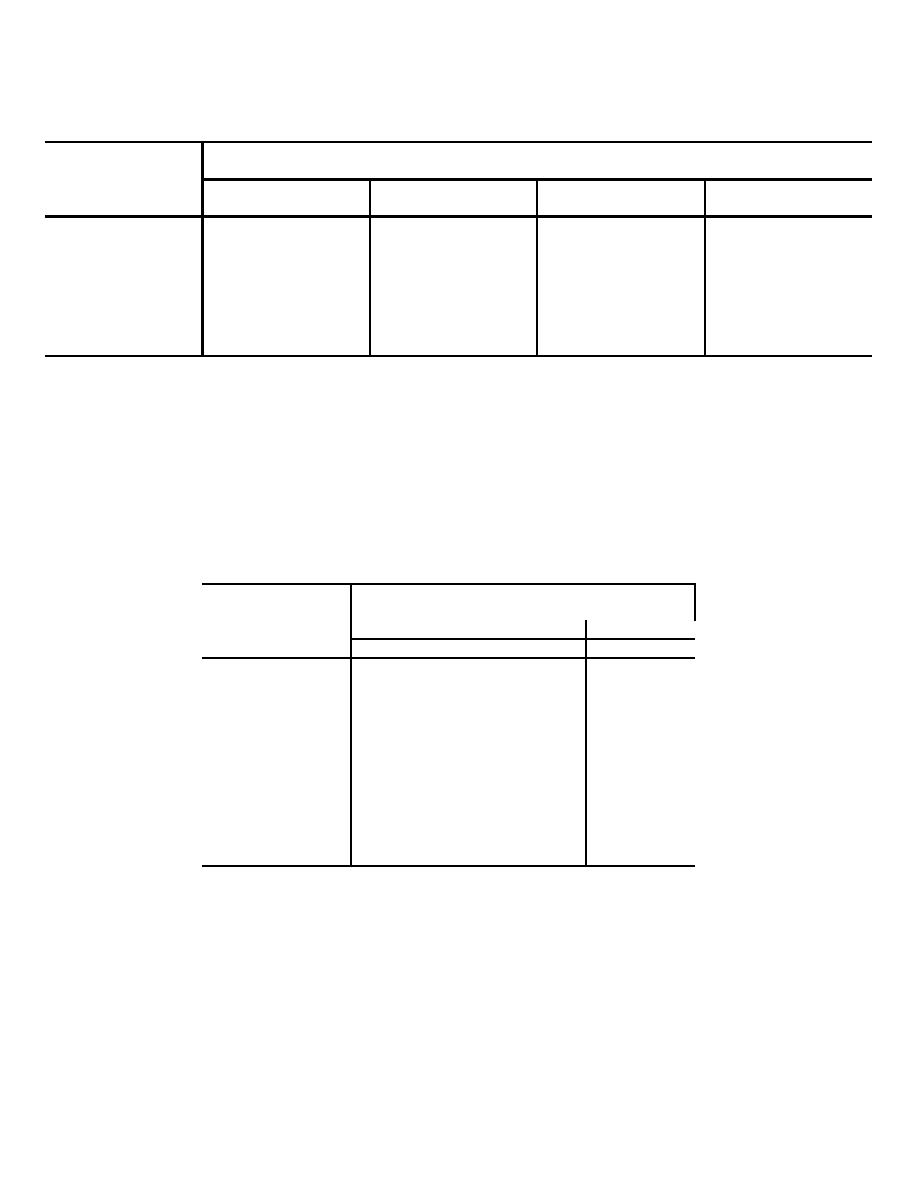

Table G- 1. General Torque Requirements for Dry Fasteners* - Continued

Torque Requirement in lb ft (N.m)

Bolt/Screw

SAE Grade

SAE Grade

SAE Grade

SAE Grade

Size

1 or 2

5

6 or 7

8

1-1/8-7 UNC

350 (475)

800 (1085)

1000 (1356)

1280 (1736)

1-1/8-12 UNF

400 (542)

880 (1193)

1050 (1424)

1440 (1953)

1-1/4-7 UNC

500 (678)

1080 (1464)

1325 (1797)

1820 (2468)

1-1/4-12 UNF

550 (746)

1125 (1526)

1325 (1797)

1820 (2712)

1-3/8-6 UNC

660 (895)

1460 (1980)

1800 (2441)

2380 (3227)

1-3/8-12 UNF

740 (1003)

1680 (2278)

1960 (2658)

2720 (3688)

1-1/2-6 UNC

870() (118())

1940 (2631)

2913 (3950)

3160 (4285)

1-1/2-12 UNF

980 (1329)

22(00) (2983)

3000 (4068)

3560 (4827)

* Torque given is for clean, dry threads. .Reduce by 10% when engine oil is used as lubricant.

Table G-2. Locknut Breakaway Torque Values

NOTE

To determine breakaway torque, thread locknut onto screw or bolt until at least two

threads stick out. Locknut shall not make contact with a mating part. Stop the locknut.

Torque necessary to begin turning locknut again is the breakaway torque. Do not reuse

Iocknuts that (do not meet minimum breakaway torque.

Minimum Breakaway Torque

Thread

Size

lb-in.

(N.m)

10-32

2.0

(0.23)

1/4-28

3.5

(0.40)

5/16-24

6.5

(0.73)

3/8-24

9.5

(1.07)

7/16-20

14.0

(1.58)

1/2-20

18.0

(2.03)

9/16-18

24.0

(2.71)

5/8-18

32.0

(3.62)

3/4-16

50.0

(5.65)

7/8-14

70.0

(7.91)

1-12

90.0

(10.17)

1-1/8-12

117.0

(13.22)

G-2