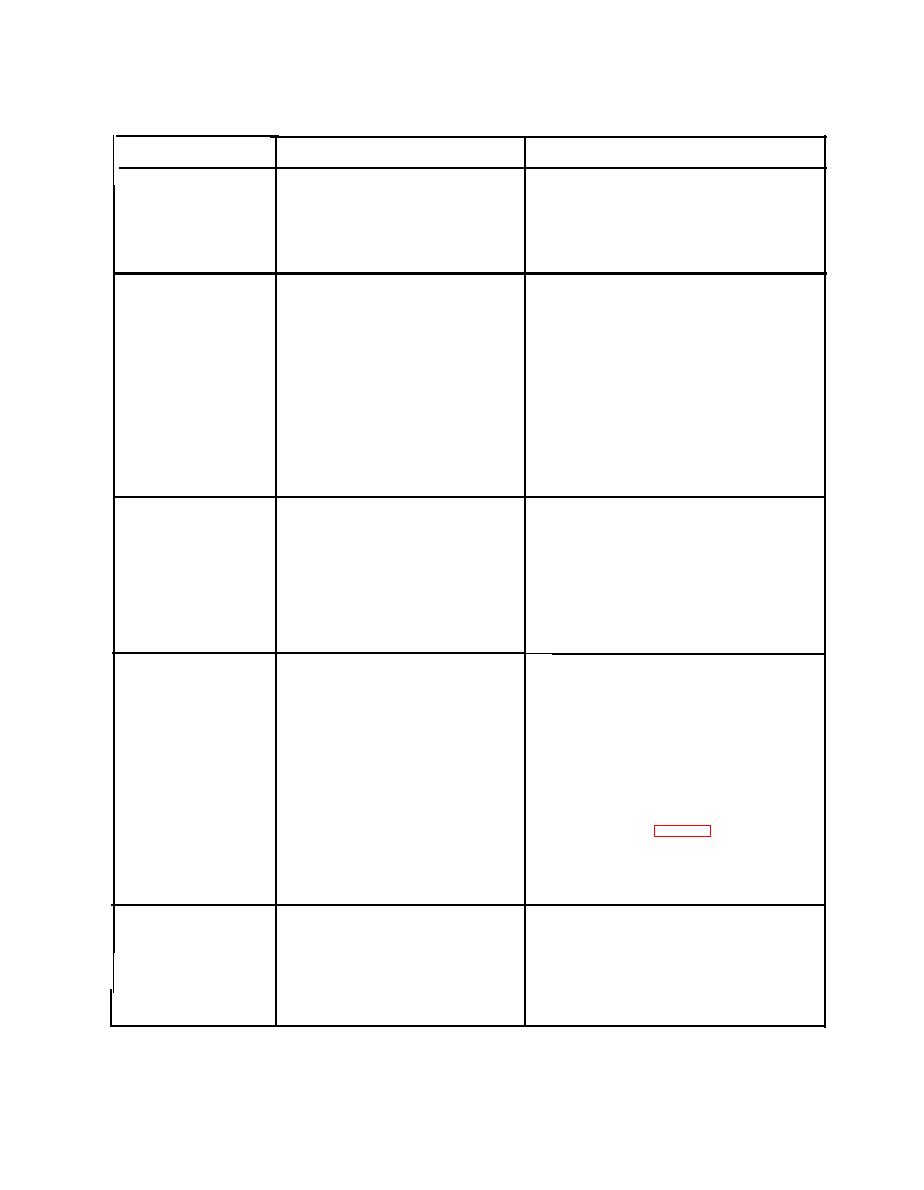

TM 9-4910-707-14&P

TROUBLESHOOTING

PROBLEM

CAUSE

REMEDY

1. Reset circuit breaker - should be at least

1. Circuit Breaker overloaded

A. Motor fails to

30 AMPS

start with switch

2. Defective switch or electric

in "on" position

2. Check switch for open or defective switch -

connection

repair connection or replace switch

3. Electric motor malfunction

3. Clean motor commutator or replace motor

assembly.

1. Check chuck and chuck jaw rollers or

1. Worn or dirty chuck jaw

B. Chuck fails to

rollers

allen screws for wearing-or chipping -

hold rim

clean or replace worn parts

2. Chuck jaws not expanding

2. Clean adapter cone threads and check

when adapter cone is

cone ramps for nicks or damage - repair

ramps or replace cone

engaged

3. Clean and lubricate screw threads or

3. Dirty or broken chuck

replace broken screw (broken screw pro-

screw

bably caused by chucking with red chuck

roller in wrong position - see chucking

decal on machine)

4. Pressure gauge malfunction

4. Check pressure gauge - no lead gauge pressure

should be 150-2-00 PSI - replace-gauge

1. Replace control cable

1. Broken control cable

C. Tire will not

raise or rotate

2. Check boom hydraulic cylinder for internal

2. Boom control cylinder mal-

leakage - replace seals inside cylinder or entire

function problem could show

cylinder

as lack of power or speed

3. Hydraulic motor malfunction -

3. Clean motor or check for internal or external

leakage - replace motor

problem could show as slow

tire rotation or lack of power

on rotation

1. Hydraulic Pump malfunction

D. Lack of speed or

1. Check pump for internal or external leakage -

replace pump

power on any

function

2. Hydraulic system leakage

2. Check individual power components for

leakage (see D2 and D3 above)

3. Suction line between tank and

pump not air tight or suction

3. Tighten line or clean suction screen

screen plugged - pump will

activate (snapping sound)

4. Bead breaking or mount-

4. Check carriage cylinder for leakage -

replace hydraulic cylinder or replace

demount inoperative or

seals inside cylinder

or malfunction

5. Adjust relief valve (figure 10- lower right)

5. Low hydraulic pressure occurs

to 1800 PSI maximum, check as shown in

mainly on mounting or

Figure 12

remounting of duplex tires

6. Change from oil to transmission fluid in

6. Unit being used primarily outside

hydraulic system

and/or in cold weather situations

1. Replace seals or broken spool valve -

1. Hydraulic control valve malfunction

E. Loss of any in-

dividual function

2. Loosen and retighten mounting screws

2. Sticking valve spools in hydraulic

on control valve unequal mount bolt

control valves - generally due to

tension can distort valve body. Valve

warpage of control valve

body distortion can also occur from

fittings screwed too tight

39