TM 55-1925-283-12&P

0006 00

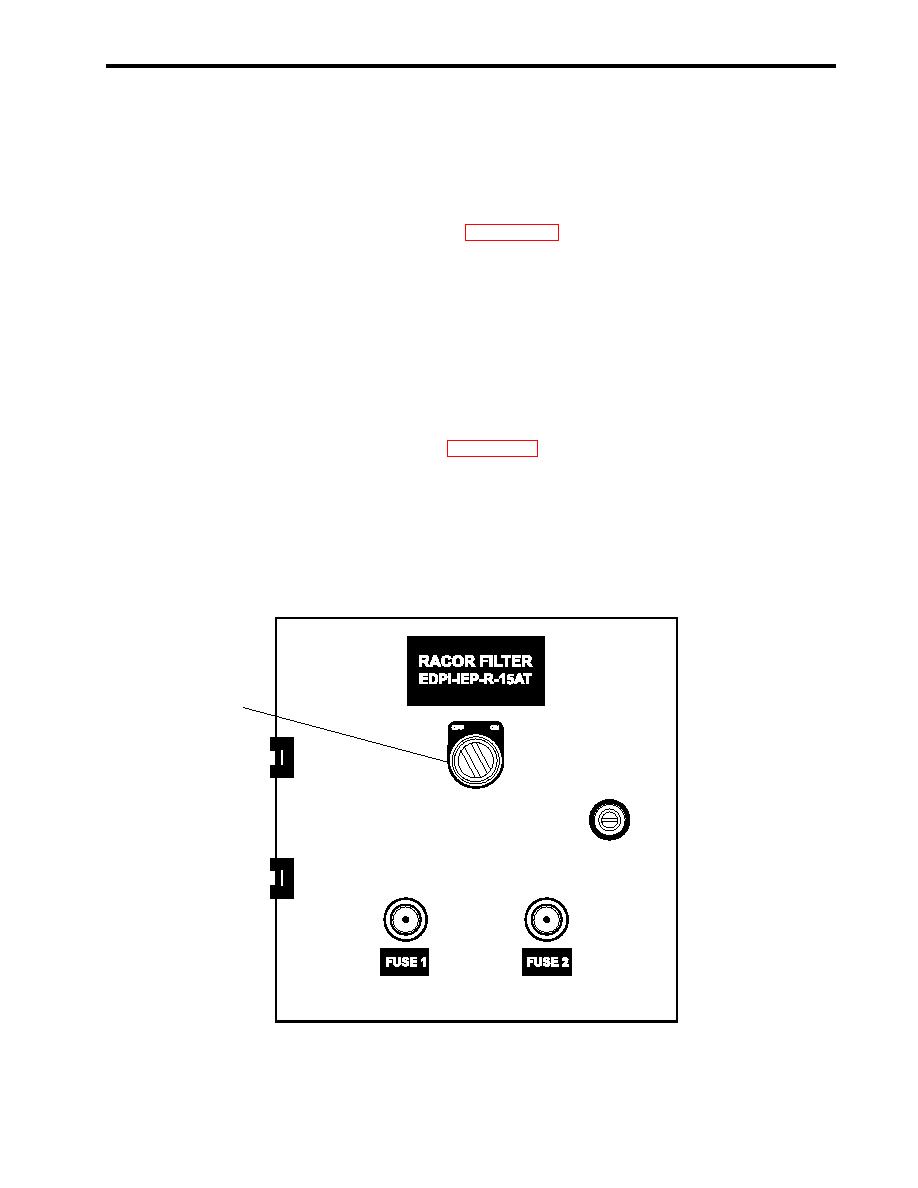

3. At the control panel, set the ON/OFF switch (figure 3, item 1) to the OFF position. No self-test will be

performed. The alarm light (figure 4, item 1) will not illuminate and the audible alarm (figure 4, item 2) will not

sound.

4. Start the desired fuel transfer pump (TM 55-1925-273-10) to begin transferring fuel.

5. Observe the readings on the inlet pressure gauge (figure 4, item 3) and discharge pressure gauge (figure 4,

item 4). If the differential pressure between these gauges exceeds 10 PSI (0.7 bar) or 10 inHg (254 mmHg),

secure from fuel transfer and change the filters (WP 0013 00). If it is necessary to transfer fuel while

changing the filters, bypass the fuel filter/water separator to permit continued transfer of fuel. The bypass

procedure is contained at the beginning of this work package.

NOTE

The sump drain interval will vary depending upon the level of contamination present in

the fuel. The initial sump drain interval should be every 15 minutes. This interval may

be adjusted depending upon the level of water and particulates present when the sump

is drained.

6. Periodically shut down the fuel filter/water separator as described in the paragraph below. After shutdown,

drain the water and particulates from the sump (WP 0013 00).

7. Continue operation of the fuel filter/water separator until fuel transfer is complete or until the differential

pressure readings exceed the value given in step 5 above. When fuel transfer is complete, shut down the

fuel filter/water separator as described in the paragraph below.

1

Figure 3. Control Panel

0006 00-3