TM 55-1925-286-13&P

0012 00

Table 1. Operator Preventive Maintenance Checks and Services Including Lubrication (continued)

ITEM

INTERVAL

MAN- ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

5

During

0.1

Air Compressor

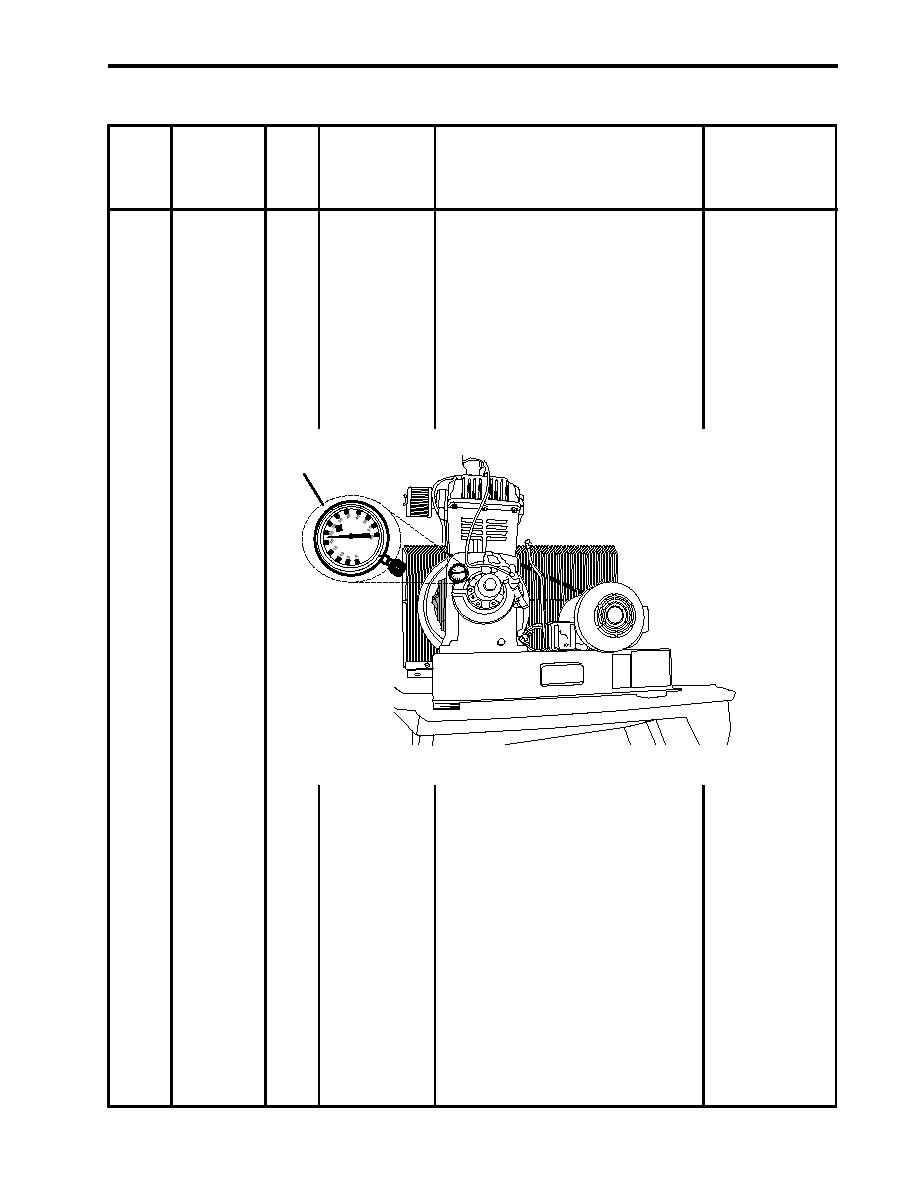

a. Check for any unusual noise or

Both compressors

vibration.

have unusual noise

or vibration.

b. Check compressor oil pressure

Both compressors

when hot. Pressure should read

have oil pressure

22 to 25 PSI (1.5 to 1.7 bar) on

below 22 PSI

the oil pressure gauge.

(1.5 bar).

OIL PRESSURE GAUGE

6

During

0.2

STARTING AIR

Check that pressure gauges read 220

Pressure greater

RECEIVERS

to 250 PSI (15.2 to 17.2 bar).

than 250 or less

than 220 PSI (17.2

or 15.2 bar).

7

During

0.2

SHIPS SERVICE Check that the pressure gauge reads

AIR RECEIVER

125 PSI (8.6 bar).

8

During

0.2

Piping

Check drop legs and traps in piping

for moisture and sediment accumulation.

0012 00-3