TM 55-1925-286-13&P

OPERATOR MAINTENANCE

AIR COMPRESSOR FOR

INLAND AND COASTAL LARGE TUG (LT)

OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES INCLUDING LUBRICATION

Table 1. Operator Preventive Maintenance Checks and Services Including Lubrication

ITEM INTERVAL MAN-

ITEM TO BE

PROCEDURE

EQUIPMENT

NO.

HOUR

CHECKED OR

NOT READY/

SERVICED

AVAILABLE IF:

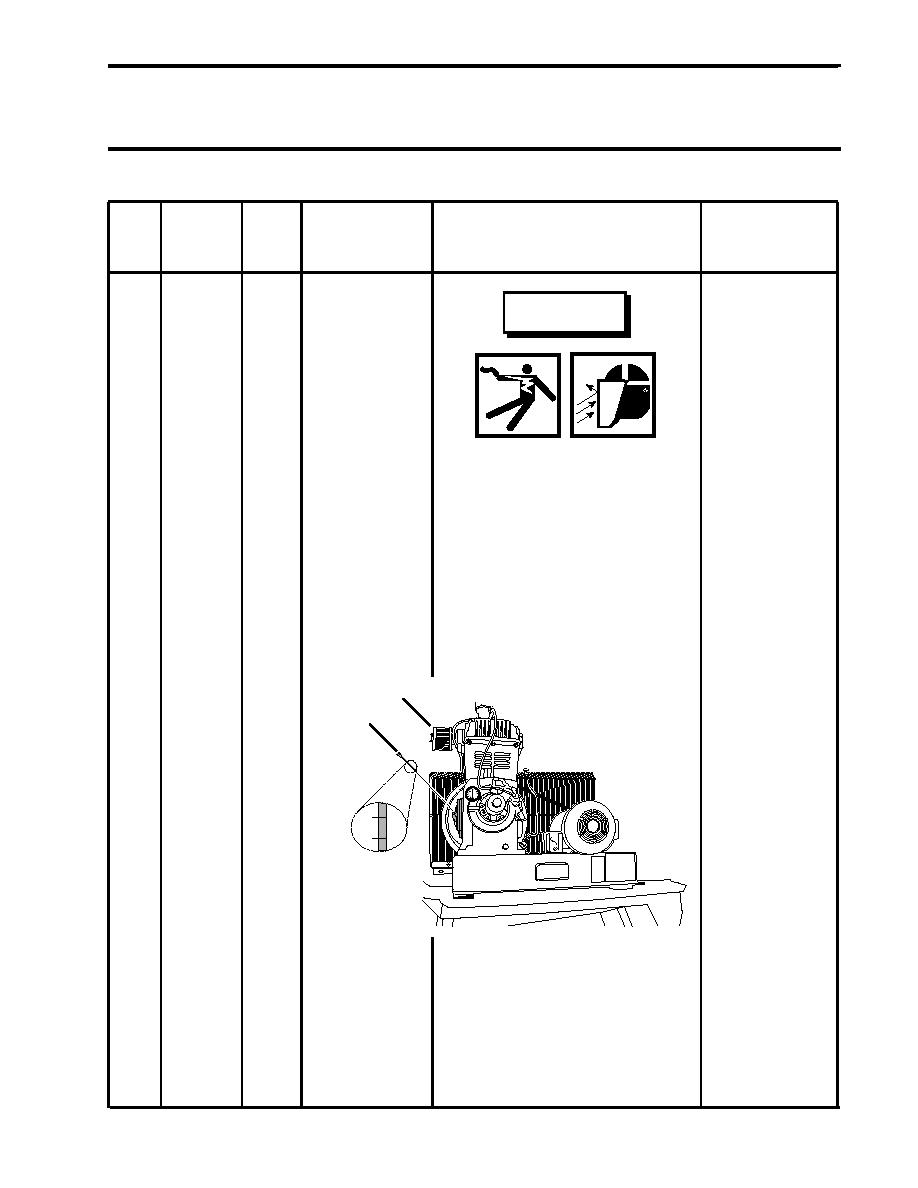

WARNING

Set to OFF AIR COMPRESSOR NO 1

or AIR COMPRESSOR NO 2 circuit

breaker in AMS 1 Power Panel

NO 4. Lock out and tag out before

checking oil. Death or serious

injury could result from servicing

an energized compressor.

1

Before

0.1

Compressor Oil

Check that the oil level is between the

Level

HIGH and LOW marks on the dipstick.

Add oil as necessary. Refer to table 2

for proper oil.

AIR FILTER

DIP STICK

HIGH

LOW

2

Before

0.2

Compressor

a. Perform an overall visual inspection, Class III leak.

ensuring that all hardware and safety

guards are in place and tight. Also

check for visible signs of oil leakage.

b. Check air filter condition. Refer to

maintenance supervisor if filter is dirty.

0012 00-1