TM 9-2320-209-10-1

OPERATION OF FUEL TANK TRUCKS.

General. M49A1C fuel trucks are equipped with a 200-gallon tank, a 400-

gallon center tank, and a 600-gallon rear tank.

M49A2C fuel trucks are equipped

with two 600-gallon tanks. Operating procedures described in this paragraph are

for both M49A1C and M49A2C fuel trucks. It should be noted that illustrations

given are for the M49A2C configuration. Certain procedures where discharge valve

control levers are operated will note two levers on M49A2C trucks and three levers

on M49A1C trucks.

b.

Gravity Filling the Fuel Tank Sections.

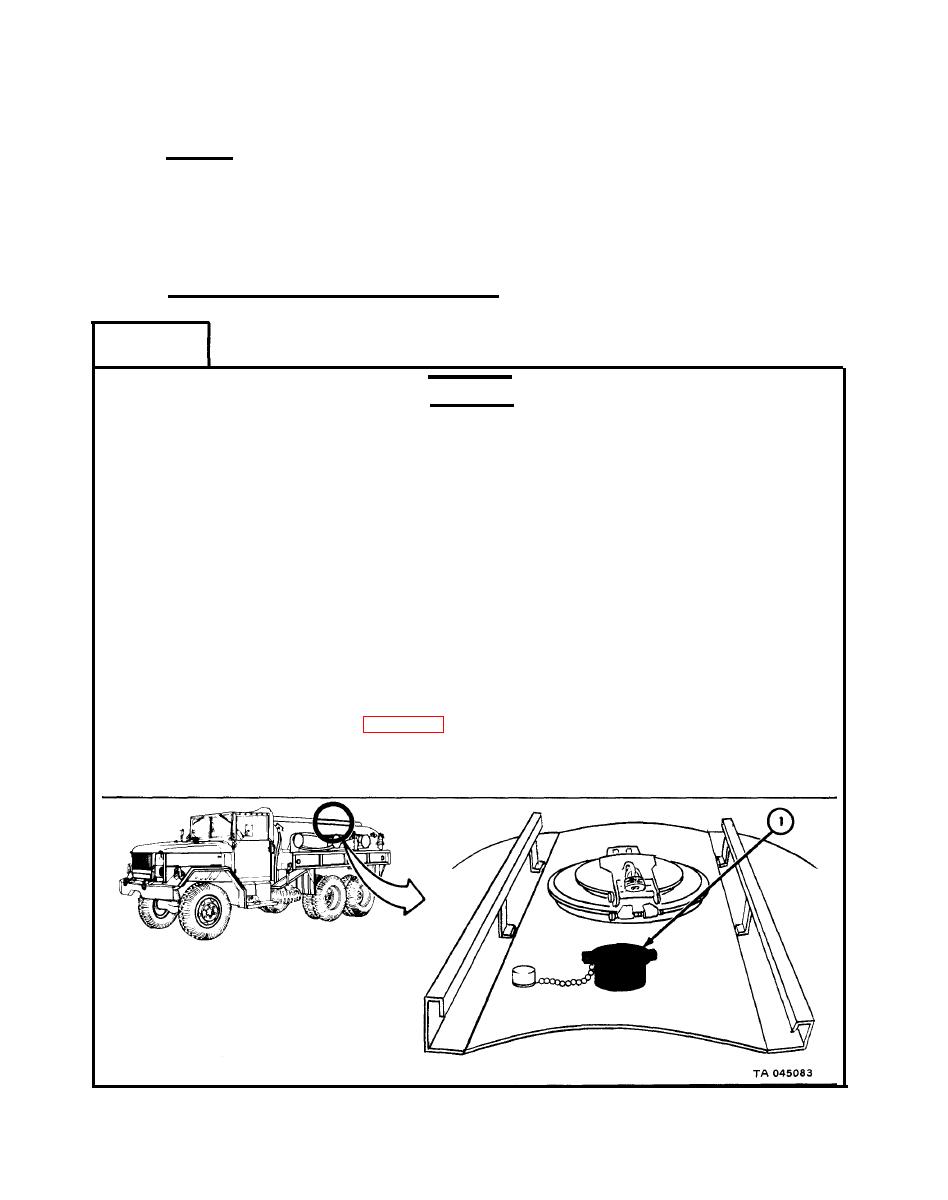

FRAME 1

WARNING

To prevent fire or explosion, smoking, flame, sparks,

and glowing or hot objects are not allowed near truck

during filling and delivery of fuel. Make sure that

rear and dispenser nozzle grounding wires are properly

connected for static discharge before transferring

of fuel.

NOTE

Drain compartments and piping system, including filter/

separator, when changing to a fuel or grade different

from the one last carried. Flush with 50 gallons of new

product, and circulate new product back to each com-

partment twice. Circulate new product through all fuel

handling components, including meter, filter/separator,

and hose reels when applicable. Get rid of this fuel

in the approved area after flushing.

1.

Start engine.

(Refer to para 4-6 b.)

2.

Place truck near fuel supply with filler hole (1) in an easy to reach position.

GO TO FRAME 2