TM 9-2320-211-10

(9) When a lift and swing operation is

required, remove two L-shaped retaining

pins (9) securing shipper braces (8) to

brackets. Swing braces up and secure to

shipper bracket (7) with L-shaped retaining

pins.

CAUTION

Do not pay out cable after hook

has reached the load or ground.

Continued drum rotation will

loosen cable on drum.

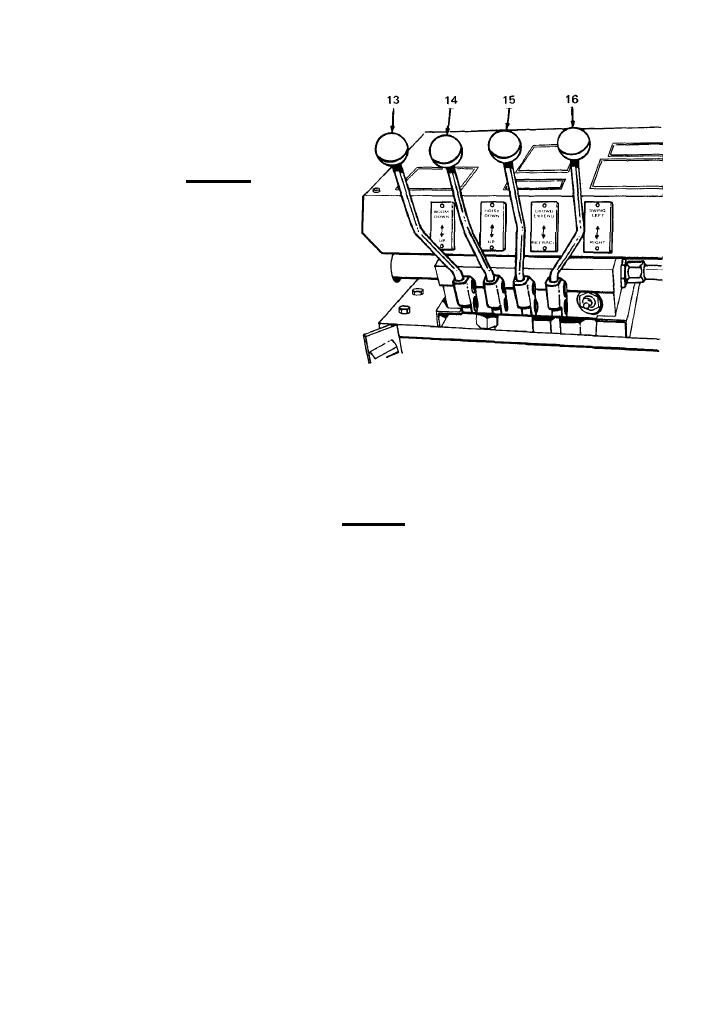

(10) Push hoist control lever (14)

forward to unwind cable and lower hook to

ground or load.

Warning

During crane operation, direct

all personnel to stand clear of

crane load. A snapped cable, or a

s h i f t i n g or swinging load, can be

extremely dangerous. Never

exceed the safe load limits.

CAUTION

When extending the boom with the crowd control lever (15), do not jam the crane

block into the boom head sheave. Pushing the crowd and hoist (14) control levers

at the same time will prevent this. This will keep the crane block a constant

distance from the boom head.

Once the load has been lifted, do not attempt to move the boom up or down, as

this may damage the boom hydraulic cylinder. If the bbom height must be

adjusted, lower load to ground or to a support with the hoist cable before adjusting

boom height.

(11) Secure cable hook (12) to load, pull back on hoist control lever (14) to raise load,

and push or pull crowd (15) and swing (16) control levers as necessary to move load to desired

position.

NOTE

The maximum boom settlement (rate of uncontrolled descent) witk a 10,000

pound load, a 11-foot 6-inch radius, and oil temperature at 100 F., should not

exceed 3 inches in 6 minutes. Settling in excess of this amount indicates defective

lift cylinders and/or control valve. Notify organizational maintenance.

TA 067081

2-107