TM 9-2320-279-10-2

Equipment Differences and Technical Data (Cont)

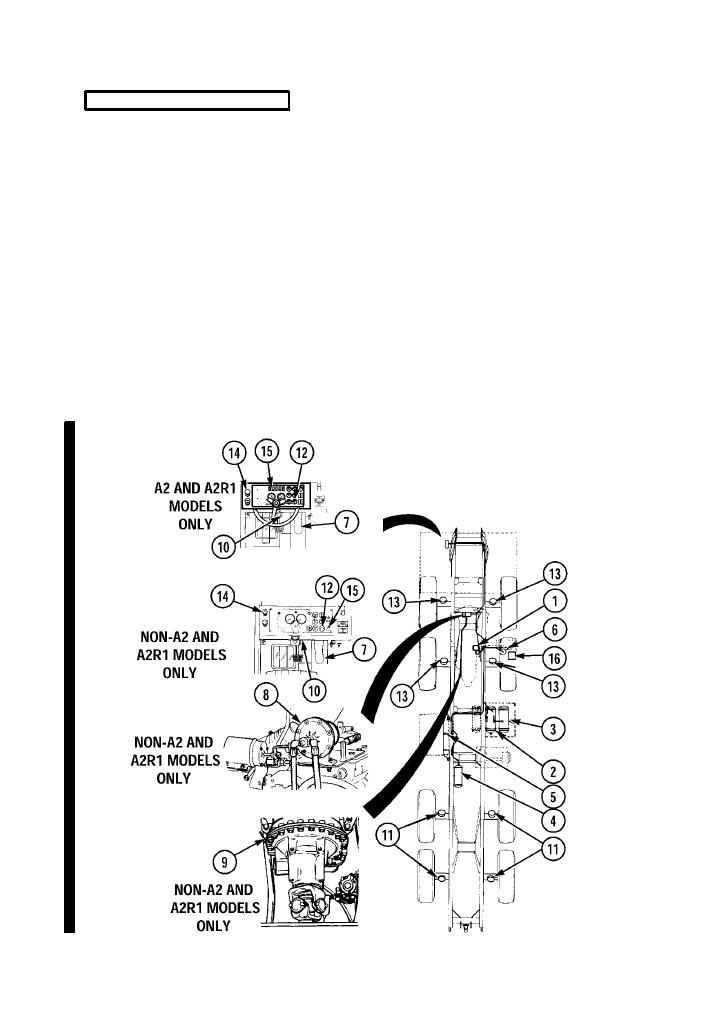

1-33. AIR SYSTEM (CONT).

Once air pressure in reservoir (2) rises above 75 psi (517 kPa), a valve opens and

allows reservoirs (3, 4, and 5) to be pressurized up to 120 psi (827 kPa). Air from

reservoir (4) goes to the brake treadle valve (10). This air controls the rear axle

service parking brakes (11). Air pressure in this system is shown by the red needle

on the AIR PRESS gage (12). Air from reservoir (3) goes to the brake treadle valve

(10). This air controls the front axle service brakes (13). Air pressure in this system

is shown by the green needle on the AIR PRESS gage (12).

The PARKING BRAKE valve (14) controls air from reservoirs (3 and 5) and

applies or releases the rear axle service (parking) brakes. Reservoirs (3, 4, and 5)

are interconnected so that if one reservoir fails, air is supplied to release the rear

axle service (parking) brakes from whichever reservoir is functioning. If air

pressure falls below 60 to 75 psi (414 kPa to 517 kPa), a buzzer will sound and

the AIR indicator (15) will light. Later versions of the parking brake valve

incorporate an automatic feature that applies the parking brakes when system

air pressure drops to 30 psi (206 kPa) or less.

On the M984A1 the front brake actuator valve (16) is used to apply the front

axle service brakes when using heavy-duty winch.

Change 7