TM 9-2320-360-10

Table 3-1. Troubleshooting (Cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2.

AIR SYSTEM LOSES PRESSURE DURING OPERATION OR AIR

PRESSURE BUILDUP IS SLOW (CONT).

Step 2.

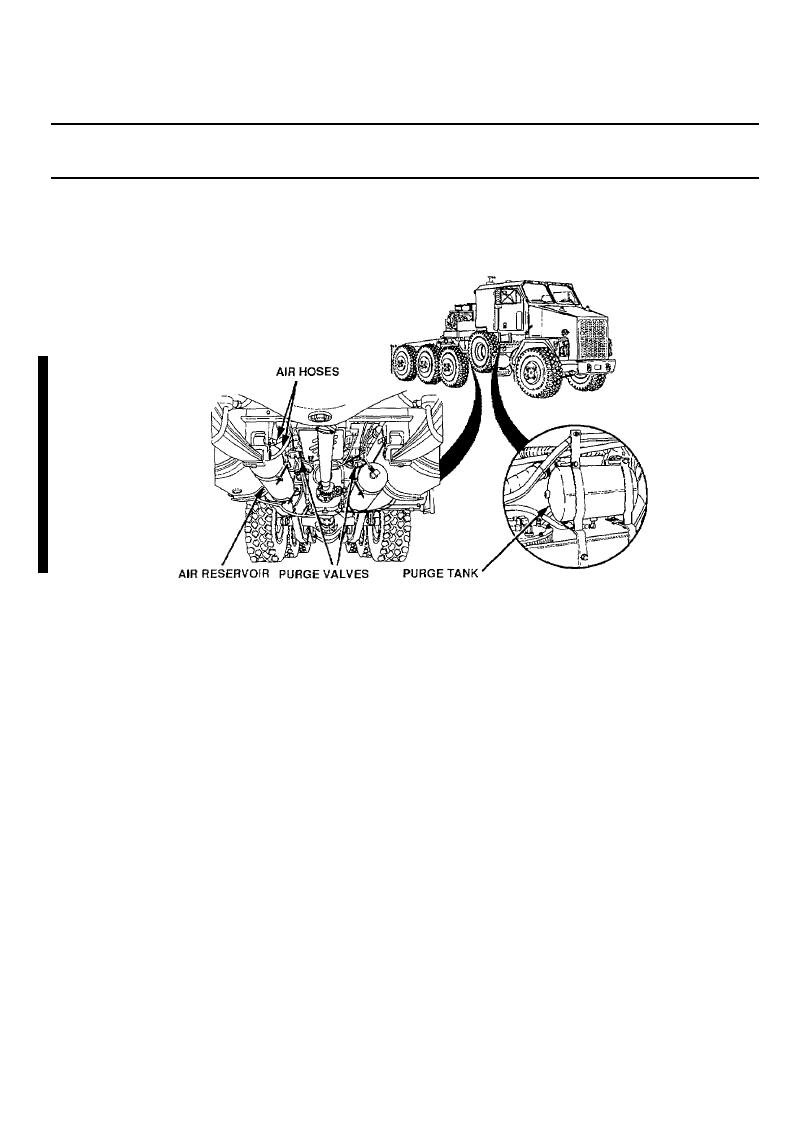

Check five air reservoirs, purge tank, and drain valves for leaks or damage.

Notify unit maintenance if air reservoirs or drain valves are leaking or damaged.

Step 3.

Check two air dryer purge valves for leaks or damage.

Notify unit maintenance if air reservoirs or drain valves are leaking or damaged.

Step 4.

Check at hoses and fittings for leaks and damage.

Tighten loose connections. Notify unit maintenance if air hoses or

fittings are leaking or damaged.

Step 5.

Operate engine at 1450-1500 rpm and allow air pressure to build up

to 120 psi (827 kPa).

Notify unit maintenance if 120 psi (827 kPa) cannot be reached.

3-18