TM 9-2330-213-14&P

2 - 8 . LEAKAGE DEFINITIONS (Con't).

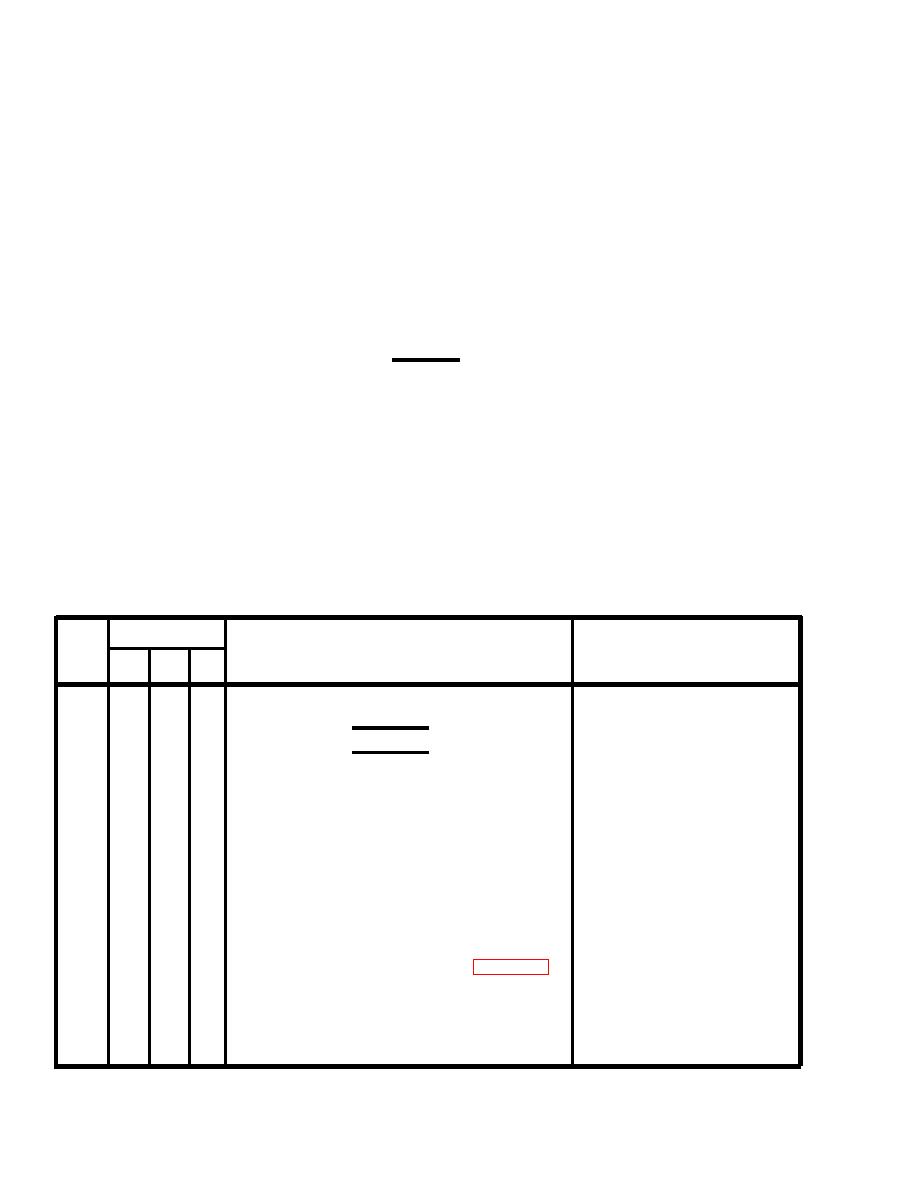

Leakage Deilnitions for Crew/Operator PMCS

Class I

Seepage of fluid (as indicated by wetness or discoloration) not

great enough to form drops.

Leakage of fluid great enough to form drops, but not great

Class II

enough to cause drops to drip from item being inspected.

Leakage of fluid great enough to form drops that fall from item

Class Ill

being inspected.

CAUTION

When operating with Class I or II leaks, continue to check fluid levels in addition to

that required in PMCS, Parts without fluid will stop working or may be damaged.

b. Equipment operation is allowed with minor (Class I or II) Leakage. Fluid leveis in an item/system

affected with such leakage must be checked more frequently than required in PMCS. When in doubt, notify your

supervisor.

c. Report Class Ill leaks IMMEDIATELY to your supervisor.

B - Before

A - After

D - During

INTERVAL

ITEM TO BE INSPECTED

ITEM

Equipment Is Not

PROCEDURE: Check for l nd have repaired,

A

B

D

NO.

Ready/Available If:

filled or adjusted as needed.

1

WHEELS AND TIRES

WARNING

DO NOT attempt to seat a Iockring when tire is

inflated, Improperly seated Iockring could fly

off. Serious injury or death will result.

Lockring not properly seated.

a. Check for proper mounting of wheel assembly

Iockring.

b. Remove any glass, nails, or other debris im-

bedded in tread.

Unserviceable.

c. Check tires for obvious damage such as cuts,

bruises, bulges, and flats.

Tire will not hold air pressure,

d. Check for proper tire pressure (para 1-10).

FRAME AND SUSPENSION

2

Cracks or broken welds pres-

Check for cracks and broken welds.

ent.