TM 9-2330-271-14&P

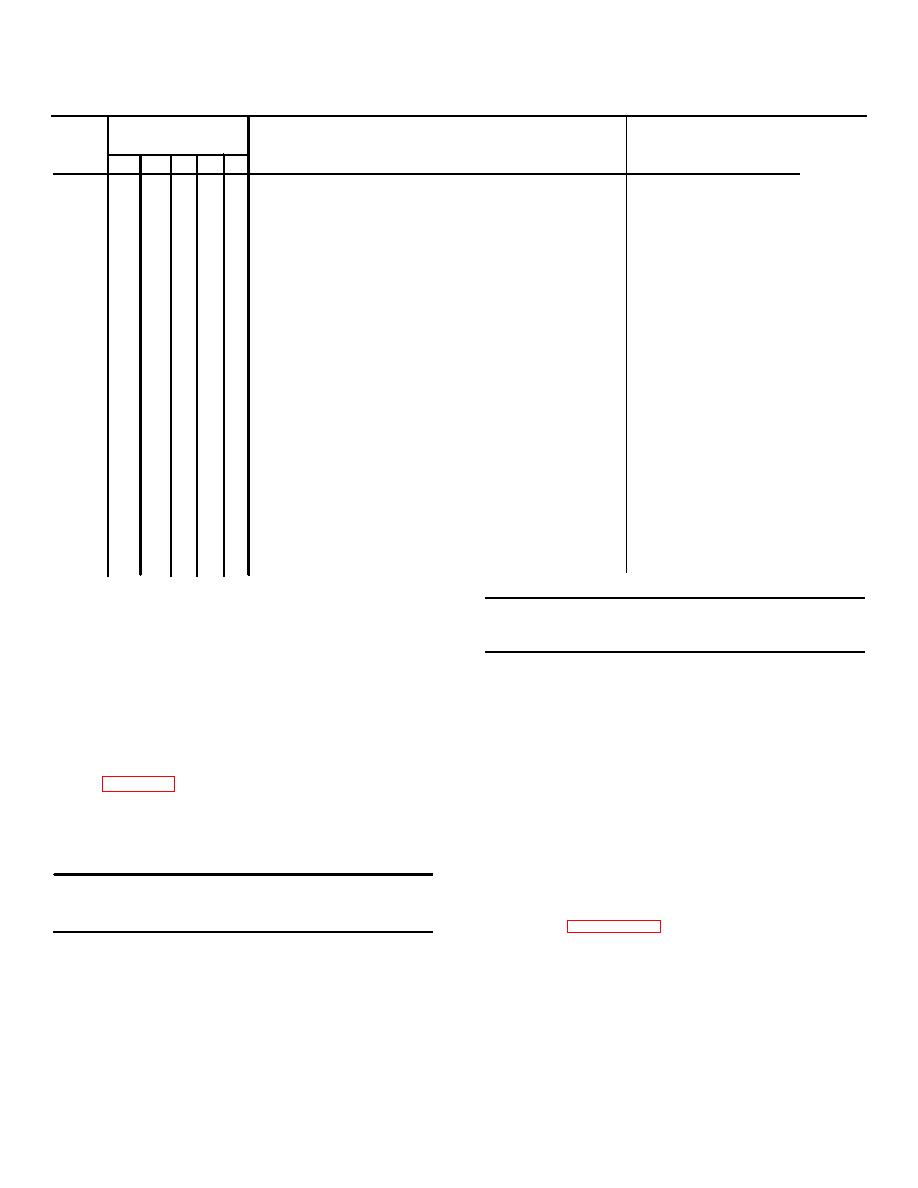

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services - Continued

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

ITEM TO BE INSPECTED

ITEM

PROCEDURE: Check for and have repaired,

Equipment is not

NO

B

D

AWM

filled, or adjusted as needed

ready/available If:

BRAKES

18

Observe operation of brakes Note any

Brakes do not operate

unsatisfactory operation (grabbing,

or do not operate properly

pulling, or slow or spongy operation)

FIFTH WHEEL/

KINGPIN

19

Observe how semitrailer tracks while

being towed In a straight line Note any

side pull, wander, or shimmy.

BRAKE DRUMS/

HEEL HUBS

WHEEL HUBS

20

Cautiously feel drums and hubs for over-

Brake drums overheating

heating. Report overheating to organi-

zational maintenance.

BODY

21

Wipe off vehicle, wash if necessary.

22

Inspect body for fading of paint and for

rust spots.

23

Inspect body for missing or damaged

reflectors and/or operating lights.

24

Check to insure that publications, basic

issue tools & equipment are present &

properly stored.

Section III. TROUBLESHOOTING

Table 3-2. Troubleshooting - Continued

3-8. Scope

MALFUNCTION

a. This

section

contains

troubleshooting

TEST OR INSPECTION

information for locating and correcting most of the

CORRECTIVE ACTION

operating troubles which may develop in the semi- trailer.

Each malfunction for an individual component, unit or

assemblies intervehicular cable receptacle.

system is followed by a list of tests or inspections which

Tighten ground connection as required

Step 2. Check to see that intervehicular cable is properly

will help you to determine the corrective actions to take.

plugged Into receptacle

b. This manual cannot list all malfunctions that

Pull cable plug out of receptacle and insert

may occur, nor all tests or inspections and corrective

properly.

actions. If a malfunction is not listed or is not corrected

Step 3. Check light switch on towing vehicle

by listed corrective actions, notify your supervisor.

Place light switch on towing vehicle In proper

mode of operation

you may find during the operation or maintenance of the

Step 4. Inspect for dirty or corroded terminals on

semitrailer or its components. You should perform the

intervehicular cable

tests/inspections and corrective actions in the order

Clean connectors, receptacle and plug (para-

graph 3-3b)

listed.

2. ONE OR MORE LAMPS WILL NOT LIGHT

Table 3-2. Troubleshooting

Step 1. Inspect for dirty or corroded terminals on

MALFUNCTION

intervehicular cable.

TEST OR INSPECTION

Clean connections, receptacle and plug

CORRECTIVE ACTION

Step 2. Check for loose cable connections

ELECTRICAL SYSTEM

Tighten connections

1.

ALL LAMPS FAIL TO LIGHT.

Step 3. Check to see if rear junction connector is loose if

Step 1. Check for loose ground connections at light

van and forward chassis lights are ON, but all

rear lights are OFF. Pull out, clean and reinsert

connector, making certain socket and contacts

are clean.

3-9