TM 9-2330-271-14&P

rebore, removing as little metal as necessary to true

friction surface. After boring, check that drum meets

requirements of repair standards listed in table 6-1 and

figure 6-1. If refinishing requires removal of more than

one-sixteenth of an inch of material (one-eighth of an

inch in diameter), replace drum.

6-5.

Axle and Bracket Assembly Seat

NOTE

The key letters shown below in

parentheses refer to figure 26 except

where otherwise indicated.

a. Removal.

(1) Support weight of semitrailer by jacking up

axle and bracket assembly at end from which spring seat

is to be removed

(2) Remove four nuts and lockwashers from

two U-bolts and remove U-bolts (fig. 4-39). Lift off

spring seat on top of spring assembly.

(3) Loosen two bolts (13) from inner face of

spring seat (15) and raise ends of main axles until

bottom of spring assembly and center bolt clears top of

spring seat

(4) Remove six bolts (22) and lock washers

(21) and remove access cover (20) and gasket (19).

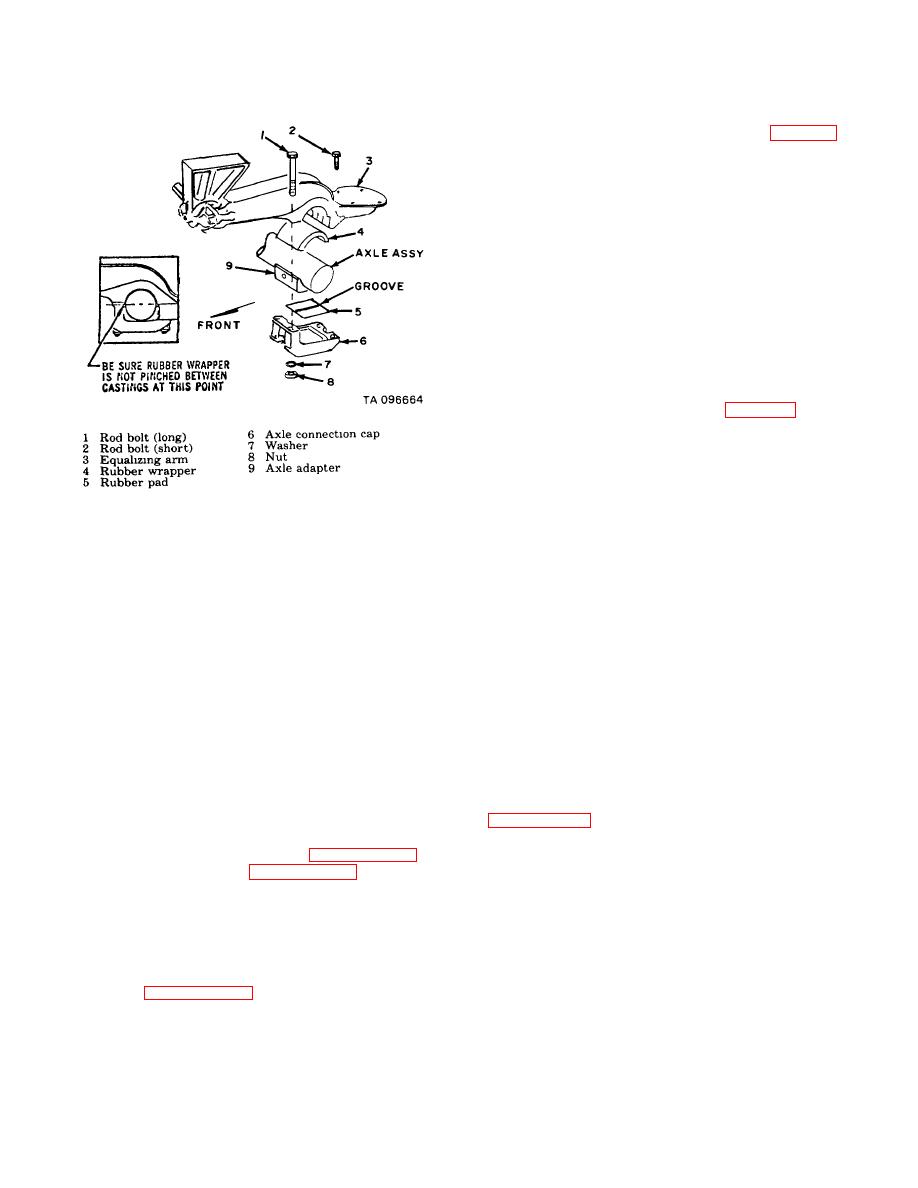

Figure 6-4. Installation of new axle.

Discard gasket if defective.

(5) Remove adjusting nuts (17) and key

(1) Connect hydraulic hose to tee at center of

washer (18), using wrench NSN 5120-00-795-0059.

axle.

Remove outer tapered bushing (11)

(2) Insert rubber wrappers (4) in position in

(6) Remove spring seat assembly (15) using

equalizing arms (3).

slight rocking motion (left and right) while carefully sliding

(3) Position axle in equalizing arms (3).

seat out and away from axle and bracket assembly (1).

(4) Place support under axle.

It is possible inner bearing cup (12) will remain in spring

(5) Check rubber wrappers (4) to make

seat.

certain they are not pinched.

(7) Remove inner tapered bushing (11),

(6) Place rubber pads (5) in axle connection

encased seal (9), packing retainer (8), flat washers (6

caps (6).

and 7) from axle and bracket assembly (1) Discard

(7) Place axle connection caps (6) under axle

seals.

and insert rod bolts (1) and (2).

b. Cleaning. Clean mud and dirt from all exposed

(8) Secure bolts (1) and (2) with eight nuts (8)

parts with water and stiff brush. Remove grease from

and washers (7).

spring seat parts with approved cleaning solvent

(9) Torque nuts (8) alternately until axle

connection caps (6) and equalizing arms (3) are a tight

c. Inspection and Repair.

fit, metal to metal.

(1) Inspect for broken or cracked parts.

(10) Install hubs and drums (paragraph 4-47).

Replace broken or cracked parts.

(11) Install wheels (paragraph 3-18b).

(2) Check bearing seats and oil seal surface

(12) Connect hydraulic hoses

on bracket for rough spots or damage. File or grind

(13) Close air reservoir drain cock.

smooth high spots, burrs, or roughness. Check that

(14) Remove blocking and support equipment

parts meet the requirements of repair standards listed in

table 6-1 and figure 6-1.

6-4.

Brake Drum

(3) Replace any part that does not meet

these standards.

If inspection (paragraph 4-47d) reveals brake drum to be

out of round or excessively scored,

6-6