TM 9-2330-294-14

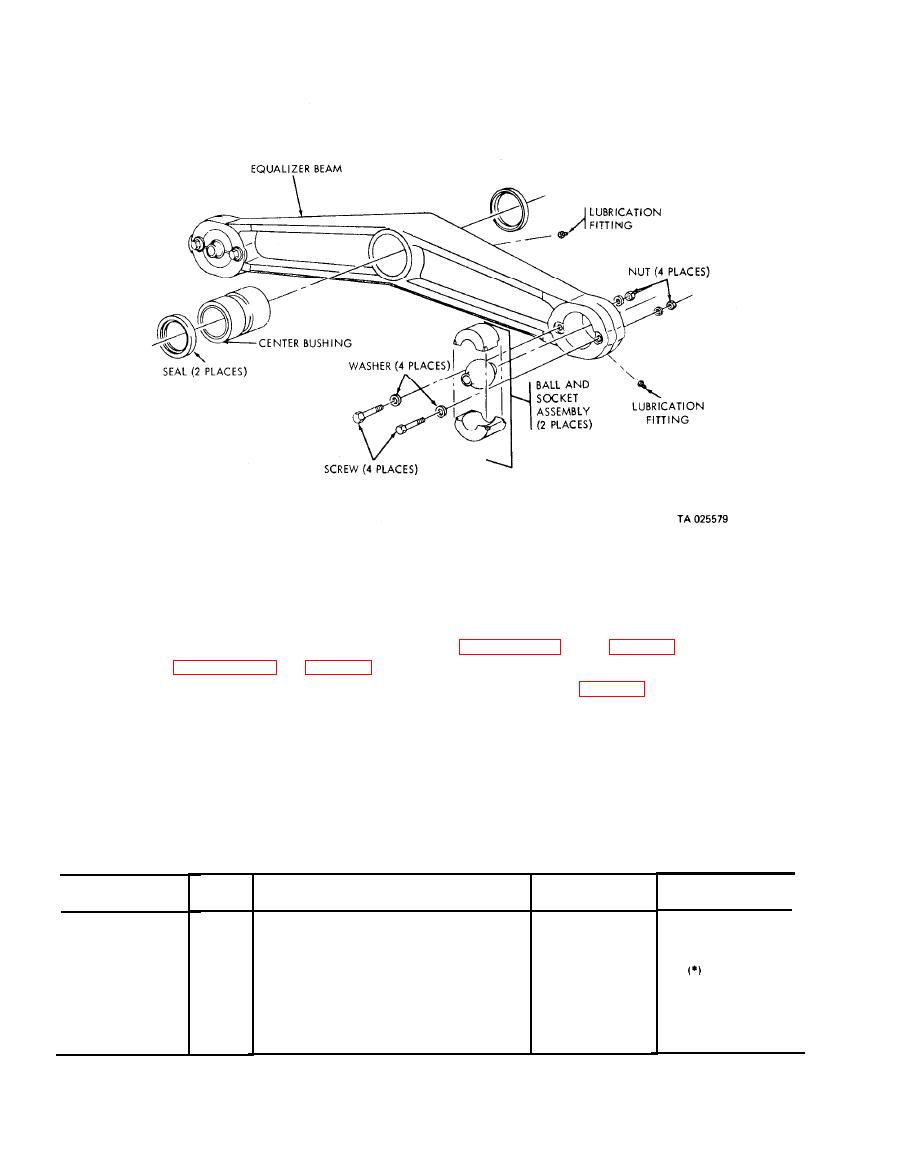

(2) Straighten bent or distorted hanger

brackets and weld cracks or breaks in brackets on

a. Cleaning. Clean all parts using dry-cleaning

axle.

solvent type II (SD-2).

(3) Replace parts worn beyond limits specified

b. Inspection.

in paragraph 6-6 and in table 6-1.

(1) Inspect components for wear and fit in

accordance with paragraph 6-6 and table 6-1.

(2) Inspect equalizer beam center bore for

The repair standards (table 6-1) give the minimum,

scoring.

maximum and critical clearance of new or rebuilt

(3) Inspect axle journals for extreme wear. No

parts. They also give wear limits which indicate the

more than 10 percent of bearing surfaces can be

point to which a part(s) may be worn before

pitted or scored. Markings cannot be over 0.002

replacement. An asterisk (*) in the wear limits

inches deep.

column indicates that the part(s) should be replaced

(4) Inspect axle for bent or distorted hanger

when worn beyond the limits given in the size and fit

brackets.

of new parts column. The leter (L) indicates loose

c. Repair.

fit.

(1) Replace damaged or defective parts.

and

Axle

Size and fit

Figure

Wear limits

Reference

letter

number

(DS&GS)

Point of measurement

of new parts

F

Beam center pin o.d.

6-2

3.997-3.999

3.994

Beam center bushing id.

4.007.4.009

G

4.011

F-G

Fit of pin in center bushing

0.008

L-0.012L

0.017L

Thrust washer flatness

c

within

0.020

E

Beam-to-axle

shaft

1.371.1.374

1.370

D

Beam end bushing id.

1,375-1.377

1 .378

D-E

Shaft (beam to axle) to beam bushing clearance

0.008L

0.00 IL. 0.006L

Axle spindle outer bearing surface o.d.

A

3.3748-3.3738

3.3733

B

Axle spindle inner bearing surface o.d.

4.1248-4.1238

4.1288