TM 9-2330-356-14

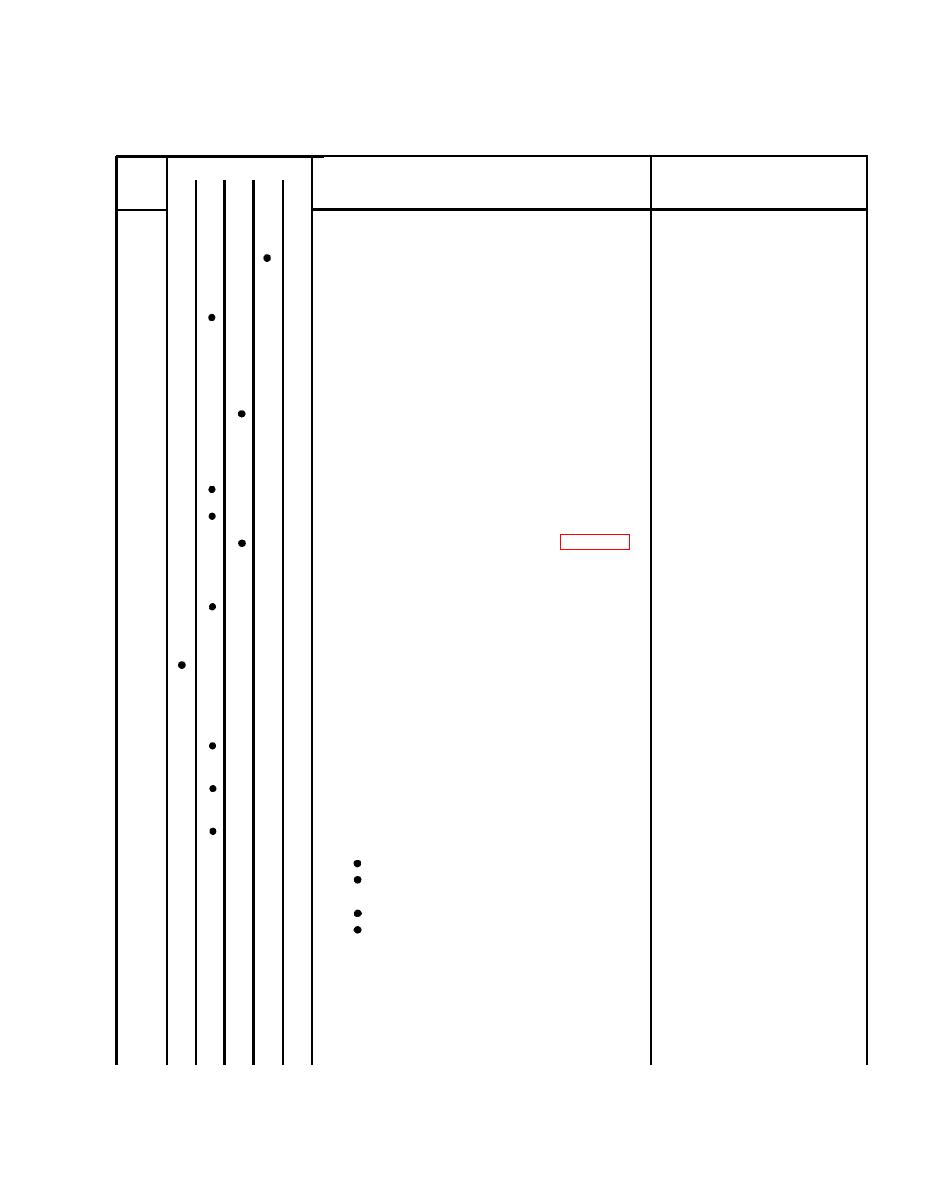

Table 3-1. Operator/Crew Preventive Maintenance Checks and Services (Con`t).

W-Weekly

M-Monthly

B-Before

D-During

A-After

INTERVAL

ITEM TO BE INSPECTED

Equipment Is Not

ITEM

PROCEDURE: Check for and have repaired,

Ready/Available If:

NO.

M

B

D

A

W

filled or adjusted as needed.

Landing Gear.

4

Mounting bolts loose or miss-

a. Inspect for loose shoes, bent or damaged

ing.

landing gear legs, and loose or missing mounting

bolts.

Landing gear legs cannot be

b. After coupling towing vehicle to semitrailer,

raised or lowered.

enage landing gear handle, and raise and lower

landing gear legs.

Piping System.

5

Pipes are damaged to an

a. Inspect all pipes for dents and cracks

extent that fuel flow will be

restricted. Pipes are cracked

allowing fuel leakage.

Leaks are evident.

b. Check all valves and couplings for leaks.

Valve is hard to open or close.

c. Check valves for proper operation.

d. Drain water from piping system (para 2-13d).

Hose Troughs.

6

a. Inspect troughs for debris. Remove any

debris found and check that water drain holes are

open.

b. Visually inspect hose lock bars for obvious

damaged or missing parts.

Control Panel.

7

a. Check switches for proper operation.

Switch does not complete its

function.

G a g e is not functioning

b. Check that preheat indicator light is lit when

properly.

engine is preheating.

c. Check gages for proper operation. Gages

should read as follows:

Voltmeter 1214V with engine running,

Oil pressure gage 3040 psi with engine

warm and running.

Fuel pressure gage 1214 psi.

Pump pressure gage:

Pump pressure gage is not

30 psi for 4-inch low-head pump

functioning properly during

(M967, M967A1, M969, and M969A1).

retail (pumping) operations.

65 psi for 3-inch high pressure pump

(M970 and M970A1).

d. Check filter/separator gage.

Gage indicates 20 psi or high-

er.

3-23