TM 9-2330-373-14 & P

4-34. AIR SUSPENSION SYSTEM (cont)

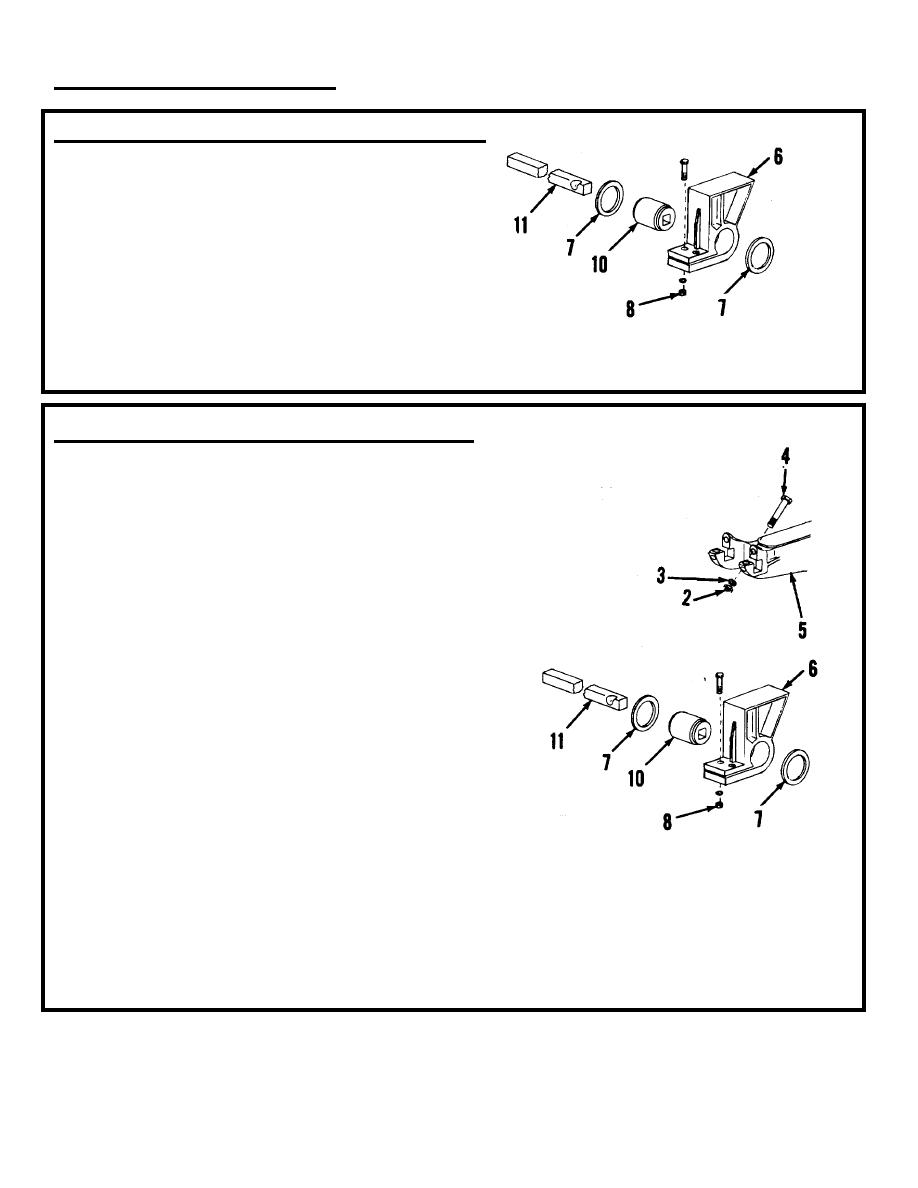

REMOVAL OF RUBBER BUSHING AND TORSION BAR (cont)

5.

Loosen nuts (8) securing frame bracket (6).

6.

Drive torsion bar (11) completely out of

assembly, using care not to mushroom torsion

bar end.

7.

Carefully let both equalizing arms down away

from frame brackets.

6.

Bracket

10.

Rubber bushing

8.

Push out rubber bushing (10) and spacers (7).

7.

Spacer

11.

Torsion bar

8.

Nut

INSTALLATION OF RUBBER BUSHING AND TORSION BAR

1.

Insert rubber bushing (10) and rotate, as near as

possible, to operating position.

2.

Place spacers (7) on ends of bushing (10) and

move equalizing arms (5) back to their positions

relative to frame brackets (6).

3.

Line up square holes in bushing with square

holes in equalizing arms to receive offset cap

screw (4).

4.

Insert torsion bar (11) through ends of equalizing

arms and bushings. Make sure notch in torsion

bar is alined to receive offset cap screw (4).

5.

Jack up axle to proper design height from

horizontal axle centerline to underside of frame

(14 inches, plus or minus one-eighth of an inch).

Tighten nuts (8) with axle in proper height

position to a torque of 150 lb-ft (203.4 Nm).

6.

Install cap screws (4), lock washers (3) and nuts

(2) and tighten to a torque of 200 lb-ft (271.2

2.

Nut

Nm).

3.

Lock washer

4.

Cap Screw

5.

Equalizing arm

6.

Bracket

7.

Spacer

8.

Nut

10.

Rubber bushing

11.

Torsion bar

7.

Reconnect linkage to height control valve.

8.

Install wheels and remove blocking and jacking equipment.

TA 314812

4-93