TM 9-2330-376-14&P

2 - 8 . LEAKAGE DEFINITIONS (Con't).

CAUTION

When operating with Class I or II leaks, check fluid levels more frequently than required

by PMCS. Parts without fluid will stop working or may be damaged.

b. Equipment operation is allowed with minor (Class I or II) leakage. Fluid levels in an item/system affected

with such leakage must be checked more frequently than required in PMCS. When in doubt, notify your supervisor.

c. Report Class Ill leaks IMMEDIATELY to your supervisor.

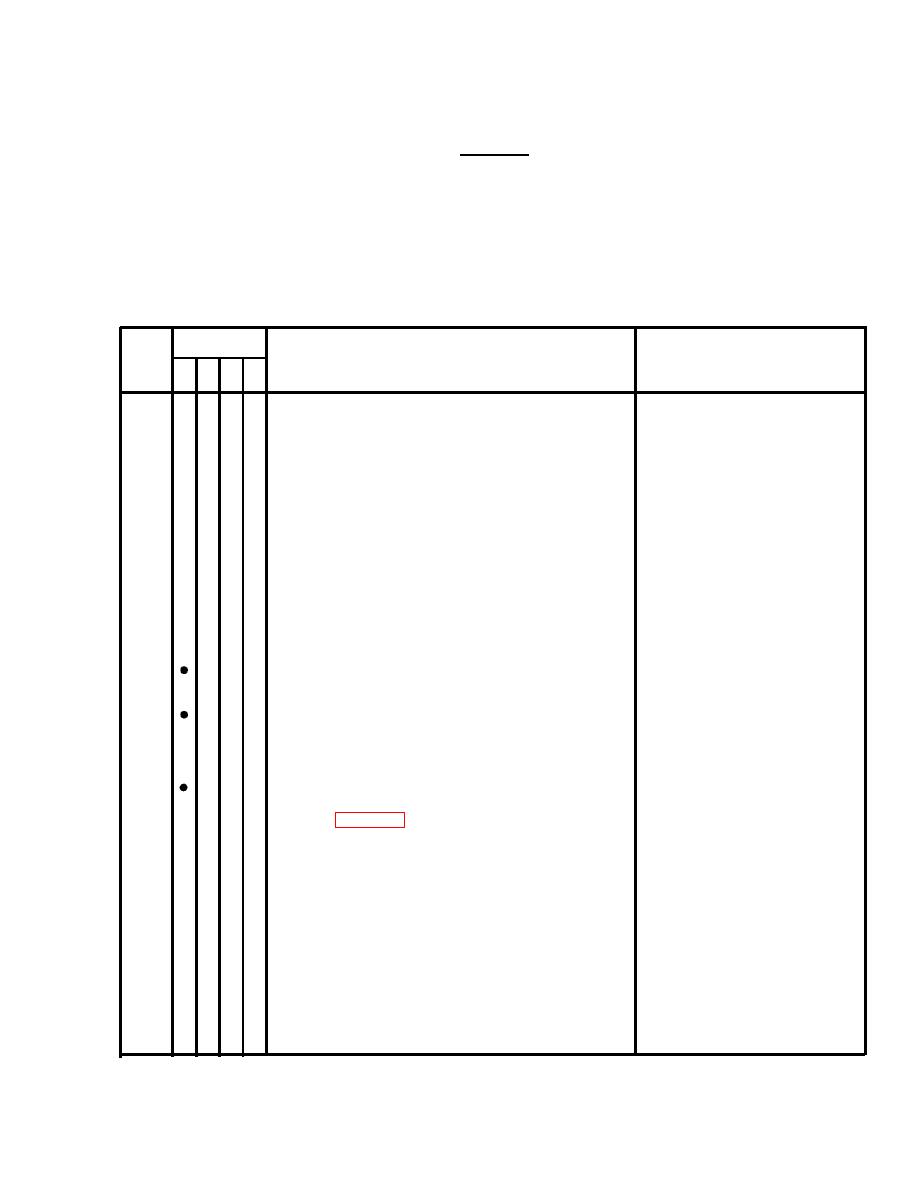

Table 2-1. Operator/Crew Preventive Maintenance Checks and Services (PMCS).

WWEEKLY

B-BEFORE

D-DURING

A-AFTER

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

ITEM

PROCEDURE Check for and have repaired, filled, or

READY/AVAlLABLE IF

adjusted as needed.

NO.

DA W

B

NOTE

ZPerform Weekly(W) as well as Before (B)

PMCS if:

a. You are the assigned operator but

have not operated the vehicle since

the last weekly.

b. You are operating the vehicle for the

first time.

Perform the following checks/services

BEFORE coupling trailer to towing

vehicle.

1

TOWING LUNETTE AND SAFETY CHAINS

Towing Iunette cracked, loose,

a. Check towing Iunette for secure mounting and ob-

bent, or welds cracked.

vious damage.

Safety chains missing or mount-

b. Check safety chains for secure mounting and ob-

ing cracked.

vious damage.

INTERVEHICULAR AIR HOSES

2

Air hose or coupling and air

Inspect trailer air couplings and air hoses for damage.

hoses broken, missing, or pre-

Clean dirt from mounting surfaces of air couplings as

formed packing missing.

required (para 3-8).

2-5