TM 9-2330-381-14

4-42. UPPER SUSPENSION ARM (CONT)

CAUTION

Alternate driving points on inner race of lower bearing cone when driving out lower

bearing cone and nonmetallic seal or damage to equipment may result.

Alternate driving points on bearing cups during removal or damage to equipment

may result.

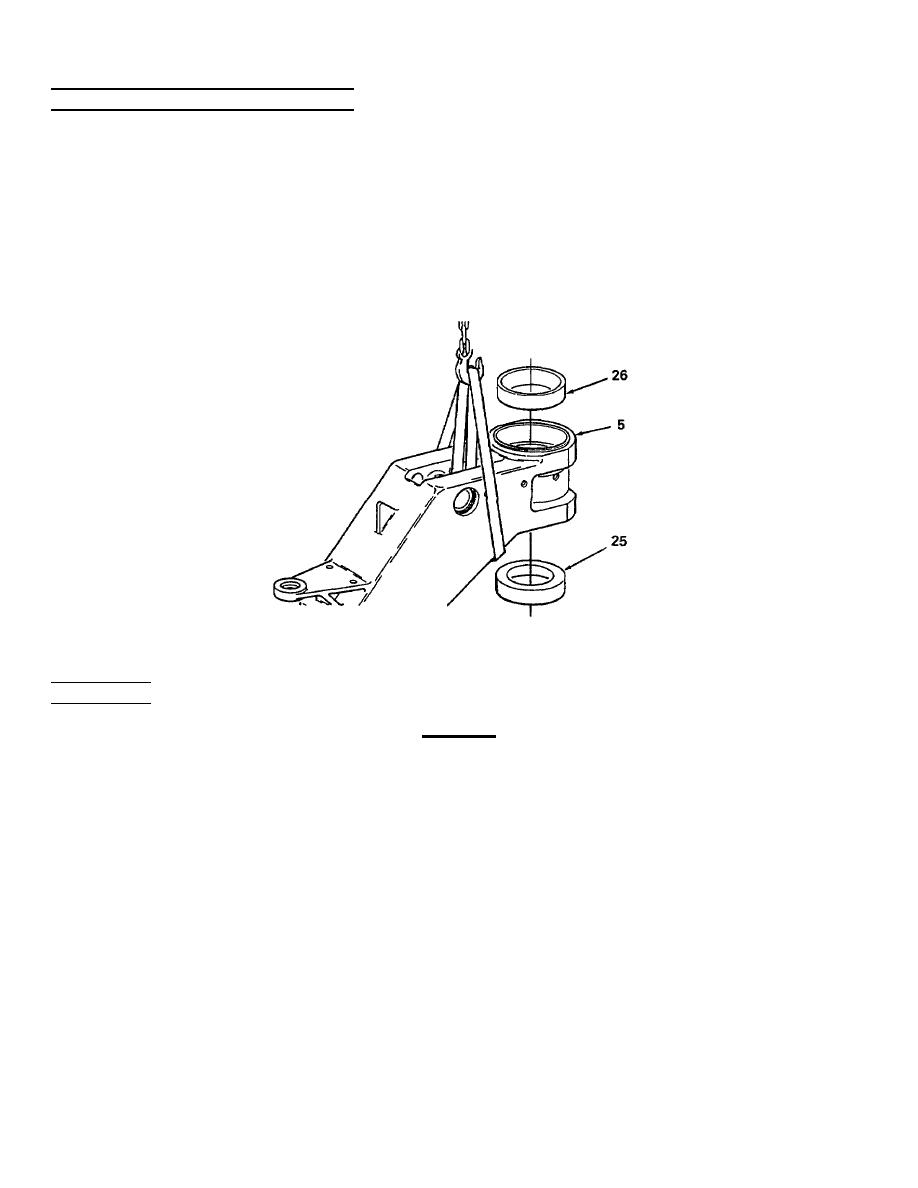

3.

If necessary, using a hammer and brass drift, drive lower bearing cup (25) from upper suspension arm (5).

4.

If necessary, using a hammer and brass drift, drive upper bearing cup (26) from upper suspension arm (5).

INSPECTION

WARNING

Cleaning compound solvent is used to clean parts and is potentially dangerous to

personnel. Extinguish all smoking materials and do not allow sparks or open

flame near the work area. Use skin and eye protection and work in a well-

ventilated area.

1.

Using wiping rags, clean all grease from inside of upper suspension arm cavity and all associated parts. Clean all

parts removed using degreaser tank with cleaning solvent. Inspect upper and lower suspension arm castings;

upper and lower bearing cups; lower bearing cone; and attaching hardware for cracks, gouges in castings, and

corrosion. Replace any parts found defective.

2.

Using an abrasive crocus cloth, remove nicks and polish scored surfaces. If casting has defects, replace casting.

4-196