TM 9-2330-381-14

3.

Inspect upper suspension bearing cone and platform spindle for cracks, gouges, scoring, excessive wear, and bent

or loose bearing cage. If defects exist, notify DS maintenance.

LUBRICATION

Using grease, bearing lubricant packer, and lubricating handgun, pressure pack lower suspension bearing cone per

lubrication chart (para. 3-3).

ASSEMBLY

CAUTION

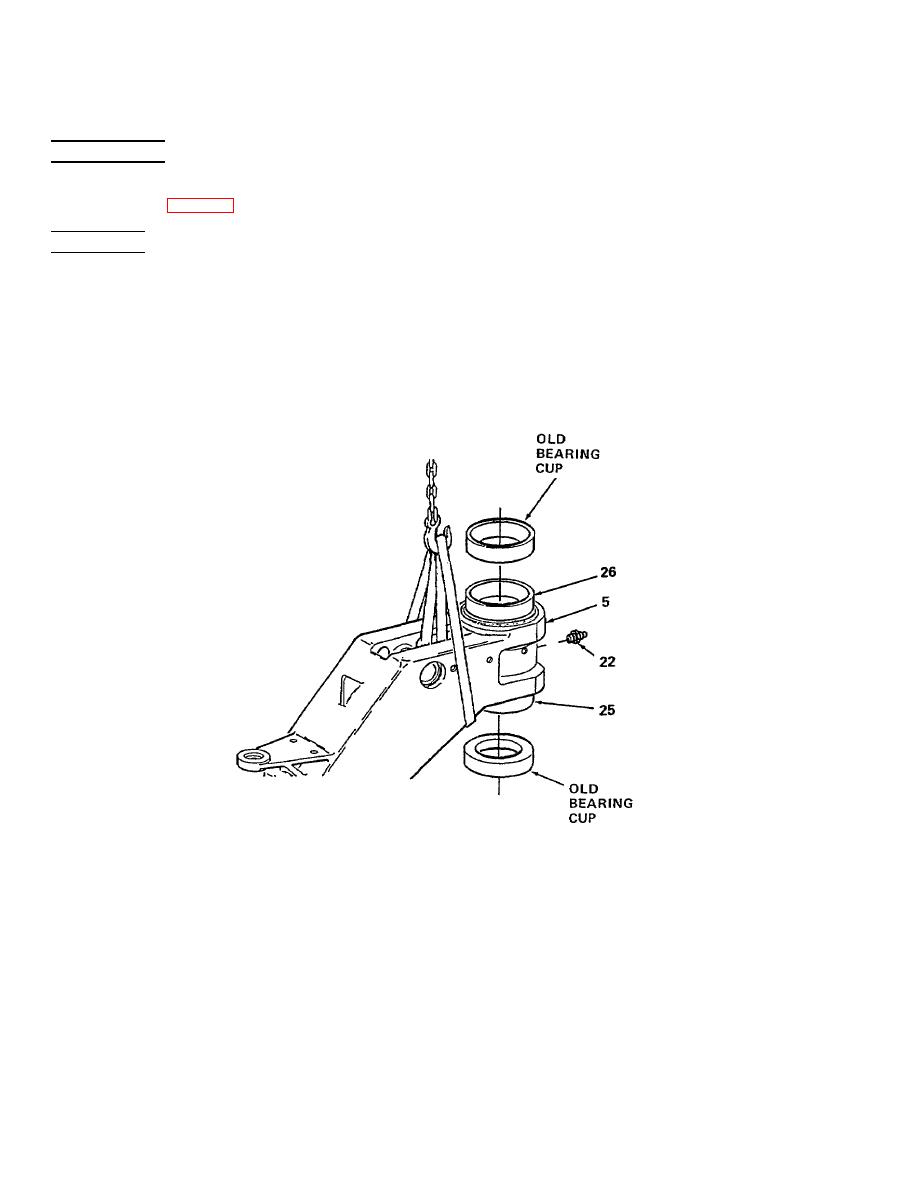

Use upper bearing cup removed during disassembly to help seat new bearing cup

or damage to new bearing cup may result.

1.

Aline upper bearing cup (26) with upper suspension arm (5) and, using a softface hammer, start seating upper

bearing cup (26).

CAUTION

Alternate driving points on upper bearing cup or damage to equipment may result.

2.

Aline existing bearing cup over new upper bearing cup (26) and, using a hammer, start driving bearing cup (26)

into upper suspension arm (5).

4-197