TM 9-2330-381-14

4-49.

PLATFORM PNEUMATICS INSTALLATION (CONT)

35.

Apply pipe sealant compound to male threads of fittings. Remove caps/plugs and install two pipe-to-tube elbows

(31), three pipe-to-tube elbows (30 and 29), two straight pipe-to-tube adapter (28), and pipe-to-tube tee (27) to air

pressure (multifunction) relay valve (32).

36.

Install air pressure (multifunction) relay valve (32) to platform weldment and secure with two screws (33) and

lockwashers (34). Using a torque wrench, torque screws (33) to 50 - 75 lb-in (5.5 - 8.0 Nm).

37.

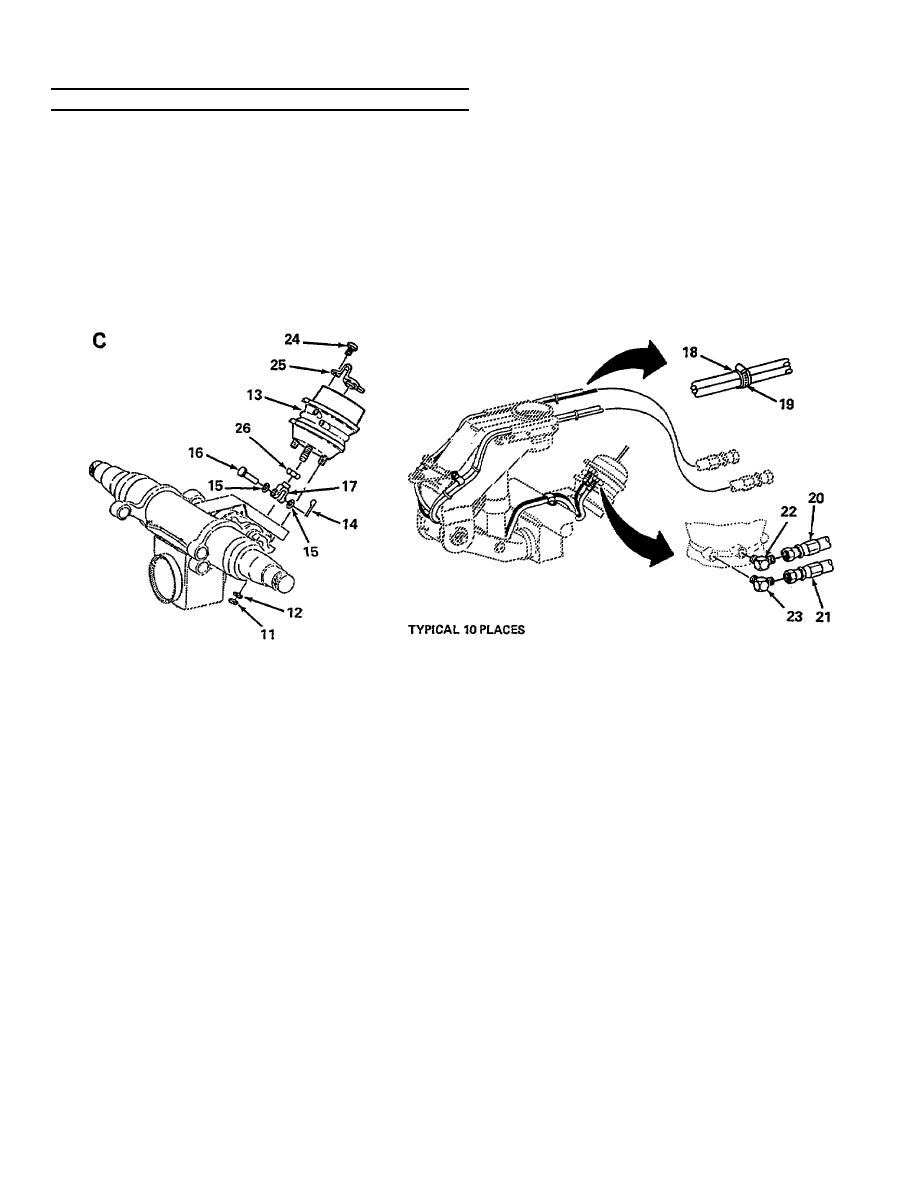

Aline and install nut (26) and rod end clevis (17) onto brake chamber assembly (13). Install nut and clevis to

same number of turns recorded during removal.

38.

Install seal plug (25) and screw (24) to brake chamber assembly (13) and aline and install brake chamber

assembly (13) onto axle.

39.

Apply pipe sealant compound to male threads of fittings. Remove caps/ plugs and install two elbow fittings (23

and 22) to brake chamber (13). Connect two nonmetallic hoses (21 and 20) to elbow fittings (23 and 22).

40.

Install two hose clamps (19) and nonmetallic channels (18) onto two nonmetallic hoses (21 and 20).

41.

Using a 15/16-inch deepwell socket, secure brake chamber assembly (13) to axle by installing two lockwashers

(12) and nuts (11). Using a torque wrench, torque nuts (11) to 80 - 125 lb-ft (108.5 - 169.5 Nm).

42.

Aline and install headless pin (16), two flat washers (15), and cotter pin (21) to rod end clevis (17).

4-234