TM 9-2330-381-14

2.

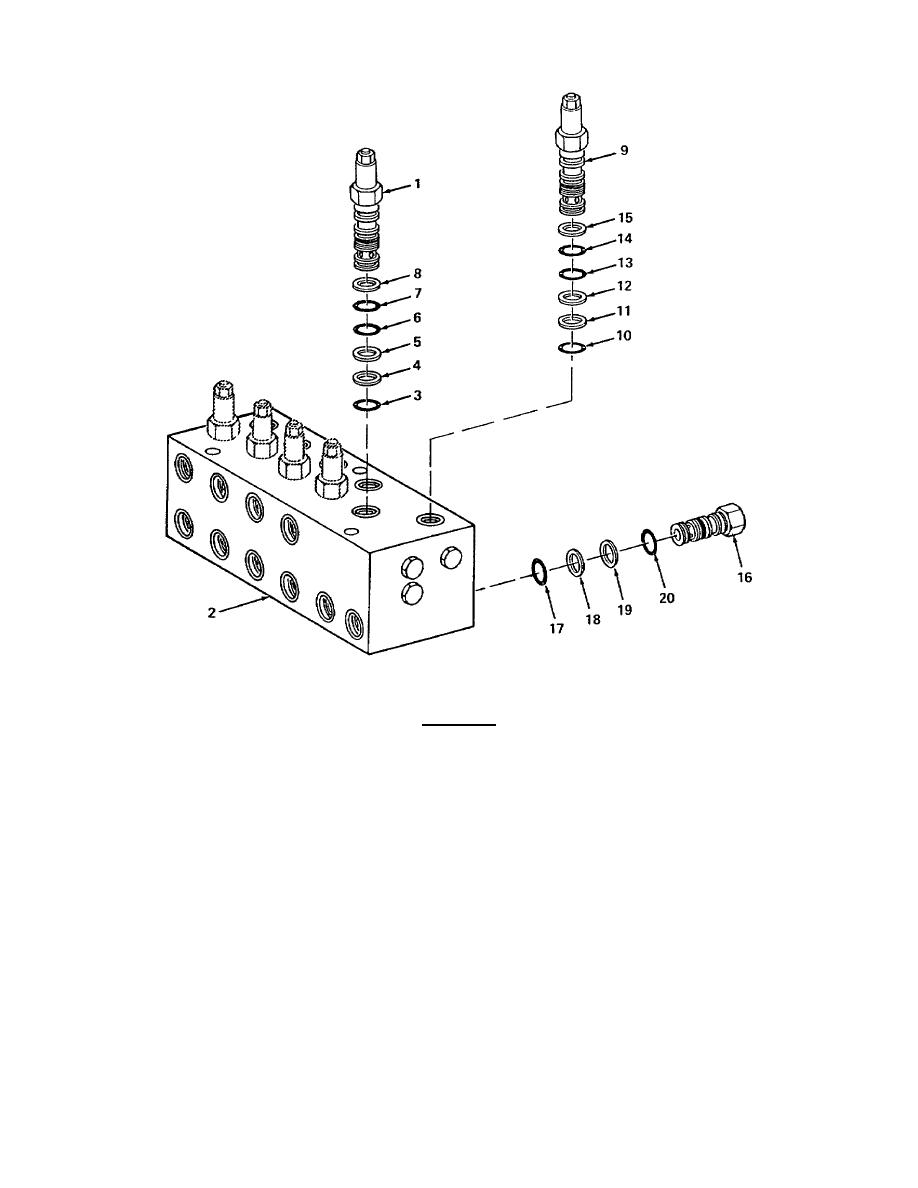

Inspect cartridge and flow regulating valves for pitting, cracks, and wear. If defective, replace parts as required.

WARNING

Compressed air used for cleaning/drying can create airborne particles that can

injure the eyes. Always wear eye protection. Pressure must not exceed 30 psi

(207 kPa) or injury to personnel may result.

3.

Inspect all ports and openings in suspension control manifold and cartridge and flow regulating valves for foreign

objects, dirt, and clogged passageways. Use compressed air to clear clogged passageways.

4.

Inspect all hydraulic tubes removed for kinks, pin hole leaks, pitted and split flares, and clogged passageways.

Use compressed air to clear clogged passageways. Replace any defective tubes.

5.

Pour clean hydraulic fluid into suspension control manifold and cartridge and flow regulating valves to flush out

4-391