TM 9-2330-384-14&P

4-35. BRAKE SHOE REPLACEMENT (Con't).

b. INSPECTION

(1) Inspect all removed components

for damage. If damaged, re-

place.

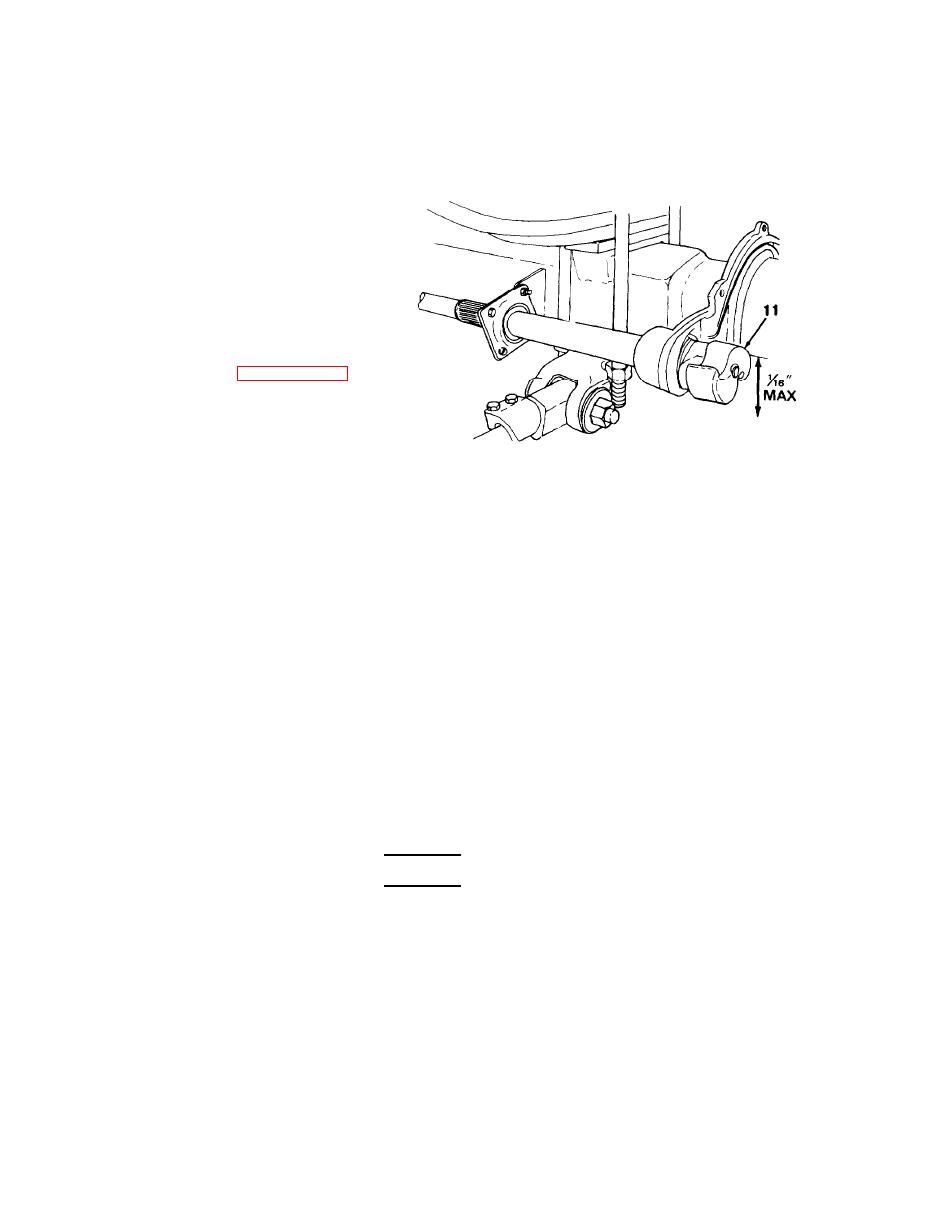

(2)

Move S-cam (11) of camshaft up

and down by hand, and use a

steel rule to measure up-and-

down movement. If movement is

greater than 1/16 in. (1.59 mm),

perform camshaft maintenance

to replace camshaft bearings and

bushing (see paragraph 4-36).

(3)

Inspect spider (7) for damage. If spider is damaged, notify direct support maintenance to

replace axle.

Inspect two anchor pins (6) for wear and looseness in bushings (5). Anchor pin should slide

(4)

smoothly inside bushing.

(5)

Install anchor pin (6) inside bushing (5) and move anchor pin up and down by hand. Use a

steel rule to measure the up-and-down movement. If movement is greater than 1/16 in.

(1.59 mm), anchor pin and bushing must be replaced.

Cut a slot in bushing (5) with a hacksaw blade. Use a chisel to drive out bushing, Discard

(a)

bushing.

(b) Grease new bushing (5).

Use a block of wood to drive bushing squarely into spider (7).

(c)

c. INSTALLATION

WARNING

Wipe clean excessive lubricant in the area of brake shoe linings to avoid

grease soaking the linings. Replace grease soaked brake shoe linings. Fail-

ure to follow this warning may cause brakes to malfunction, resulting in

serious injury or death to personnel.

(1)

Apply an even coat of grease to two anchor pins (6) and bushings (5). Wipe off excess

grease.

(2)

Position top brake shoe (2) over spider (7).

(3)

Install two new shoe retainer springs (1) to top brake shoe (2) at anchor pin (6) end.

4-102