Custom Search

|

|

|

|

||

|

||

TM 9-2330-394-13&P

PREVENTIVE MAINTENANCE CHECKS AND SERVICES,

0042 00

INCLUDING LUBRICATION INSTRUCTIONS - Continued

Semiannual PMCS Procedures for Trailer (Field Level) - Continued

Table 10. Preventive Maintenance Checks and Services (PMCS) - Semiannual (Field Level) -

Continued.

FIELD-LEVEL MAINTENANCE

EQUIPMENT

ITEM

INTERVAL

MAN-

ITEM TO BE

PROCEDURE

NOT READY/

NO.

HOUR

CHECKED OR

AVAILABLE IF:

SERVICED

2

Semiannual

Wheels, Hubs -

Continued

WARNING

If personnel become dizzy while using Dry Cleaning Solvent, immediately get fresh air and

medical help. If Dry Cleaning Solvent contacts skin or clothes, flush with cold water. If Dry

Cleaning Solvent contacts eyes, immediately flush eyes with water and get medical

attention. Failure to comply may result in serious injury or death to personnel.

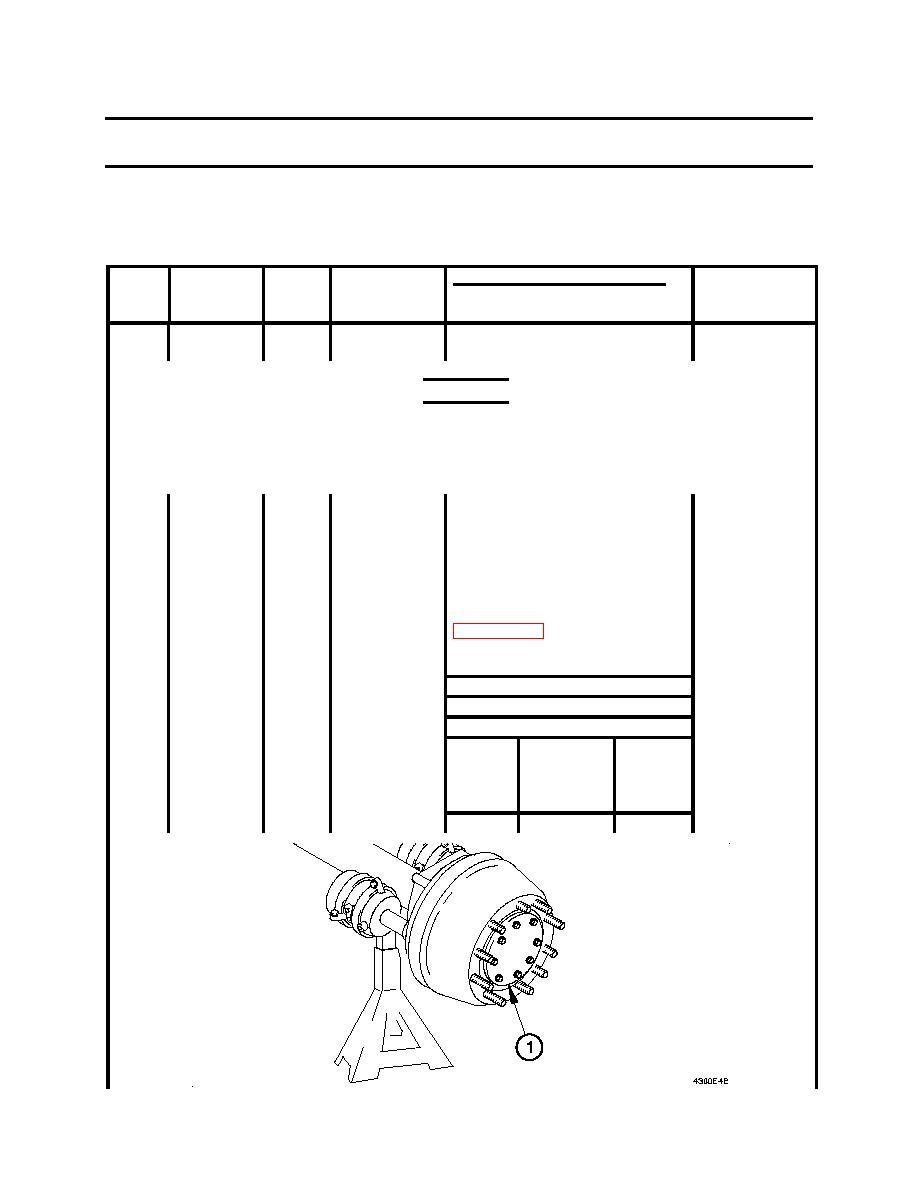

a. Clean old grease from hub,

bearing cones, and hub cap using

Dry Cleaning Solvent P-D-680.

b. Allow cleaned parts to dry.

c. Wipe Dry Cleaning Solvent away

with a clean wiping rag.

d. Install wheel end components

Seal Replacement) and pack inner

and outer bearing cones with GAA.

Wheel End Hub

Interval: S

Temperature

Above

+40F to -

-15F to -

+40F

15F

50F

(Above

(+4C to -

(-26C to

+4C)

26C)

-46C)

GAA

GAA

GAA

0042 00-57

|

||

|

||