Custom Search

|

|

|

||

TM 9-2330-394-13&P

TORQUE LIMITS

SCOPE

This work package provides general torque limits for screws and nuts used on the trailer. Special torque

limits are shown in the maintenance procedures for applicable components. Use the general torque limit

given in this work package when specific torque limits are not given in the maintenance procedure. These

general torque limits can not be applied to screws that retain rubber components. The rubber components

will be damaged before the torque limit is reached. If a special torque limit is not given in the maintenance

instructions for a fastener which retains a rubber component, tighten the screw or nut until it touches metal,

then tighten one more turn. Whenever possible, the tightening force (torque) should be applied to the nut

side of the fastener group.

TORQUE LIMITS

Refer to Table 1. Dry Torque Limits for SAE and ANSI Fasteners for torque limits on standard (SAE and

ANSI) screws and free spinning nuts. Refer to Table 2. Dry Torque Limits for SAE and ANSI Prevailing

Torque Nuts for torque limits on standard (SAE and ANSI) self-locking nuts. Refer to Table 3. Dry Torque

Limits for Metric Screws and Free Spinning Nuts for torque limits on metric screws and free spinning nuts.

Refer to Table 4. Dry Torque Limits for Metric Prevailing Torque Nuts for torque limits on metric self-locking

nuts. Refer to Table 5. Wet Torque Limits for SAE and ANSI Screws and Free Spinning Nuts for torque

limits on standard (SAE and ANSI) screws and free spinning nuts.

USE OF TORQUE TABLES

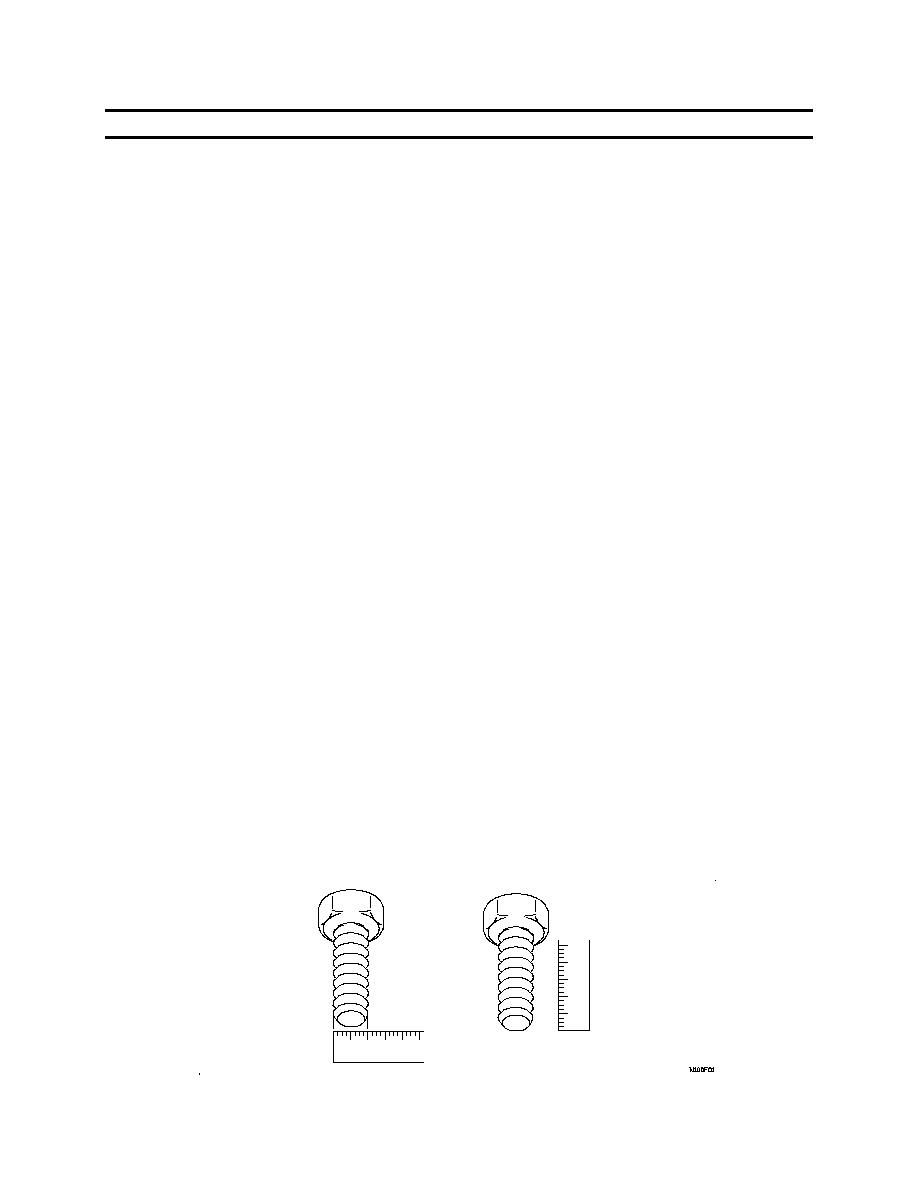

1.

Measure the diameter of the screw to be installed.

2.

Count the number of threads per inch.

3.

Under the heading DIAMETER look down the column until the diameter of the screw is found. (There

are usually two lines beginning with the same diameter.)

4.

Under the heading THREADS PER INCH (SAE and ANSI) or THREAD PITCH (metric), find the number

of threads per inch that matches the number counted in step (2).

5.

To find the grade of the screw, match the markings on the head to the correct picture under

CAPSCREW HEAD MARKINGS on the torque table.

6.

Look down the column under the picture found in step (5) until the torque limit (lb-ft or Nm) for the

diameter and threads per inch (or thread pitch, in the case of metric fasteners) of the screw are

located.

0180 00-1

|

||

|

||