TM 9-2590-209-14&P

c. Leakage Definitions for Crew/ Operator PMCS.

given to the fluid capacity in the

item/system being checked/inspected.

When in doubt, notify your supervisor.

CLASS I

Seepage of fluid (as indicated by wetness

or discoloration) not great enough to form

When operating with Class I or II leaks,

drops.

continue to check fluid levels as required

in your PMCS.

CLASS II

Leakage of fluid great enough to form drops

but not enough to cause drops to drip from

Class III leaks should be reported to

item being checked/inspected.

your supervisor or to organizational

maintenance for corrective action.

CLASS III

Leakage of fluid great enough to form drops

that

fall

from

the

item

being

checked/inspected.

2-6. Specific Procedures.

a. Preventive maintenance checks and services to

CAUTION

be performed daily each time bulldozer is operated are

listed in table 2-1.

Equipment operation is allowable with

b. Refer

to

TM

38-750

for

recording

of

minor leakages (Class I or II). Of course,

malfunctions.

consideration must be

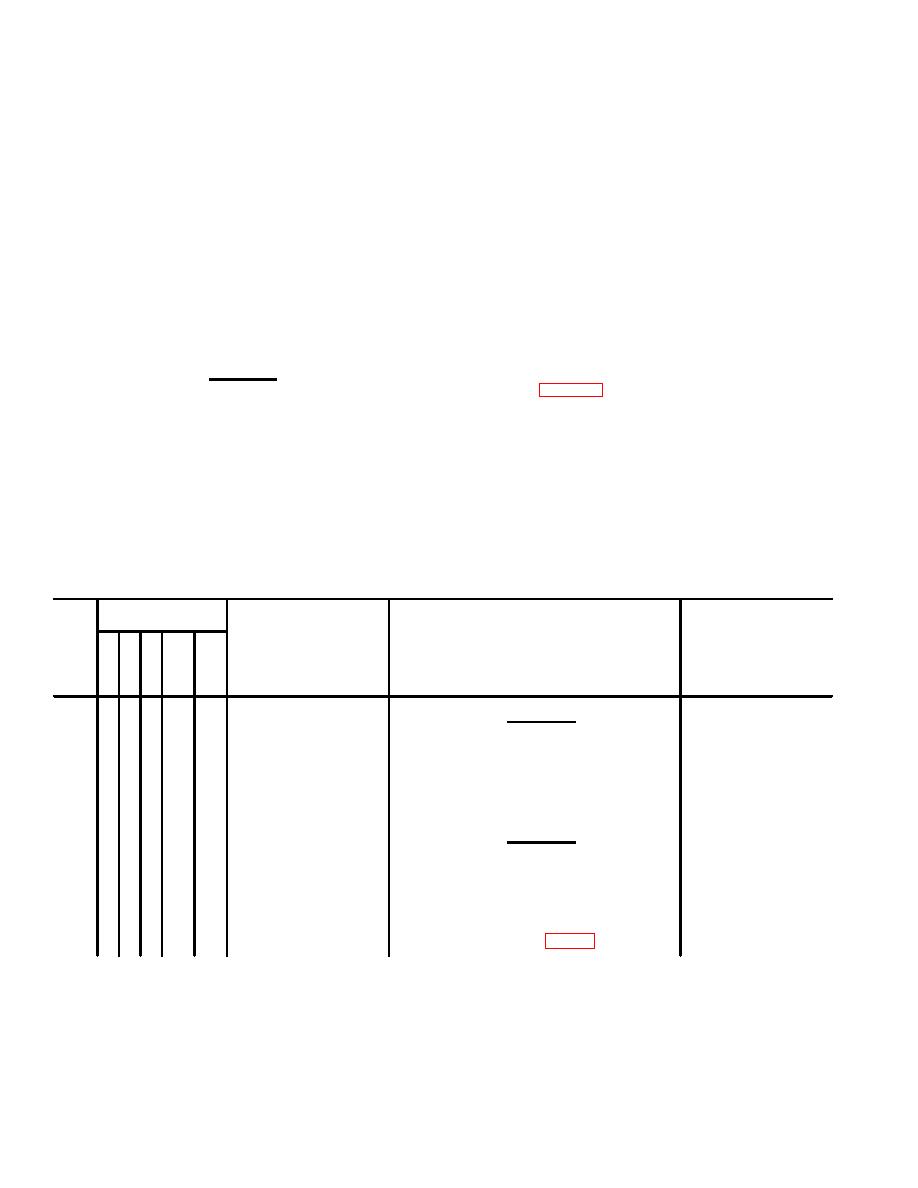

Table 2-1.

Operator/Crew Preventive Maintenance Checks and Services.

NOTE: Within designated interval, these checks are to be performed in the order listed.

B - Before

A - After

M - Monthly

D - During

W - Weekly

Item

Interval

Item to be

Procedures

Equipment

No.

Inspected

Check for and have repaired or

will be

BDAW

M

adjusted as necessary

reported Not

Ready (Red)

if:

CAUTION

Before, during, and after operation

check for evidence of oil leaks, for

Class m

loose or missing bolts, nuts, clamps,

oil leak.

and other hardware, and for unus-

ual noises.

CAUTION

Oil in reservoir must be maintained

at proper level for satisfactory

performance of hydraulic pump.

1

RESERVOIR

Check oil in reservoir. Fill to FULL

mark on dipstick (fig 3-1).

2-9