TM 9-2590-209-14&P

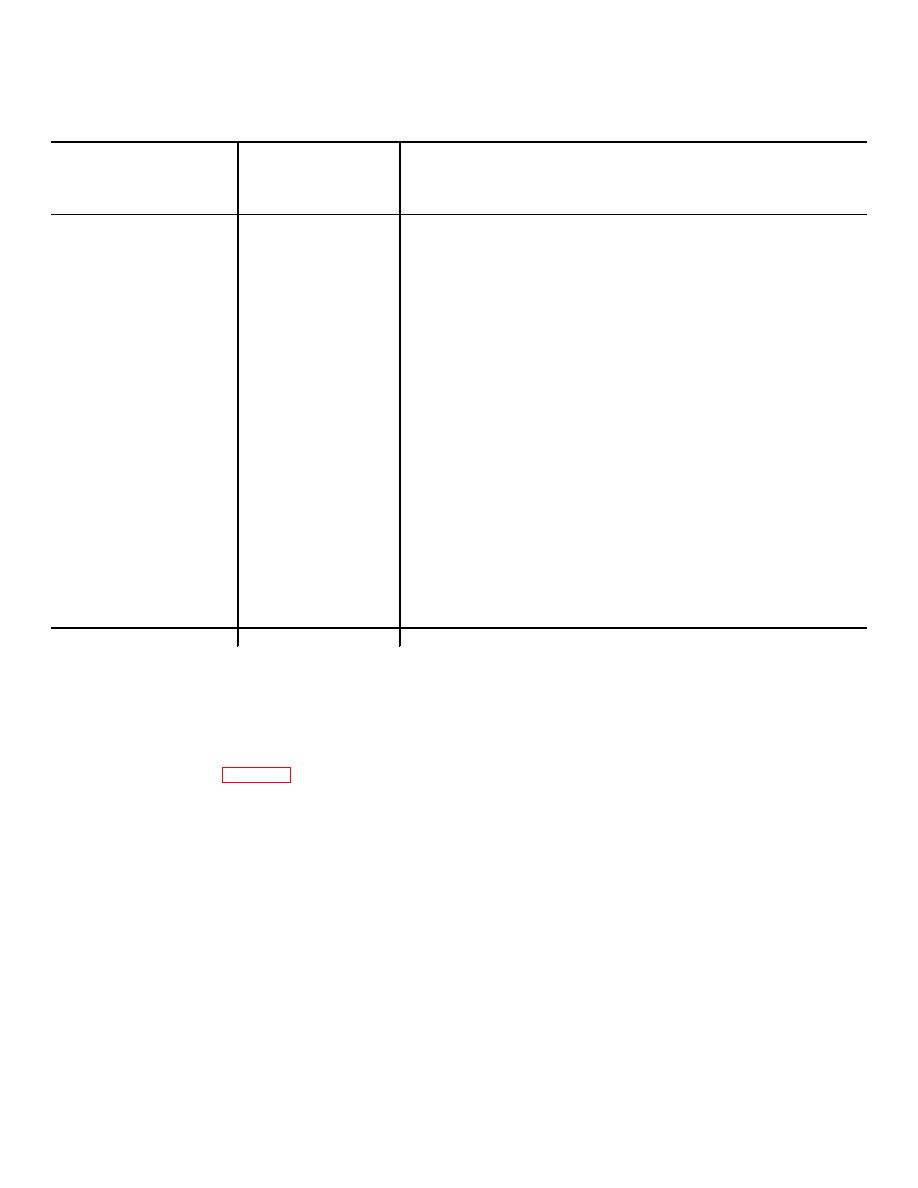

Table 10-3. Organizational Preventive Maintenance Checks and Services

Quarterly Schedule (Early Model Bulldozer).

Item

Item

To Be

No.

Inspected

Procedures

1

Tilt Arm

Inspect tilt arm pins, nuts, and cotter pins for

security and/or damage.

2

Blade Assy

Inspect hooks, shafts, arm, coupling, and handle

Carrying

for wear and/or distortion.

Hooks

3

Blade Assy

Inspect for distortion that could damage pins,

and Pushbeam

screws, lockwashers, and locks.

4

Right-Angle

Inspect operation of blade assembly to determine

Drive Power

that mechanical clutch is operating.

Takeoff

Assembly

NOTE

If operation of blade assembly is slow or jerky,

check oil level in reservoir and refill if

necessary.

5

Mechanical

Inspect for loose mechanical linkage.

Clutch

Check clutch for correct adjustment.

(6) Disconnect adapter assembly from

(4) Remove rivet (20), nut (4), ring (3), and

headlamp mount.

gasket (6) from adapter.

c. Inspection. Inspect assemblies/parts for

(5) Invert the adapter assembly and

remove seven contacts (10), insert (11), and gasket (12).

wear and/or damage. If repair is required, continue with

the following procedures.

(6) Remove three screws (1), washers (2),

d.

Disassembly (Fig 10-9).

lockwashers (8), and nuts (9), securing base (13) to

adapter (7).

(1) Turn adapter assembly with base (13)

(7) Remove gasket (6).

down.

(8) Remove cable (17) from adapter (7).

(2) Remove seven pins (21) and insert

(11).

(9) Remove grommet (18) and rods (16)

and (19) from cable.

(3) Remove three screws (1), washers (2),

lockwashers (8), and nuts (9) securing holder (5) to

adapter

(7).

10-15