CHAPTER

4

MAINTENANCE

HEAD ASSEMBLY

Wipe oil on the post occasionally and run the post up and down through the slide block several

times. The upper wheel slide and band tension screw are lubricated by grease fittings. The

wheel bearings are sealed and lubricated for life at assembly.

If it is necessary to adjust the band tension indicator, first loosen the set screw clamping the wire

leading to the indicator. Then take all slack out of the band with the band tension control. Adjust

the indicator pointer to zero and lock the linkage arm to the wire. A more accurate calibration can

be obtained by using a band tension measuring instrument.

REPLACING WHEEL TIRES

When the tires are completely worn out, replace them by loosening the tire with a screw driver or

other flat tool and stretching it until it can be taken off. Scrape the wheel clean, and apply new

cement before installing a new tire.

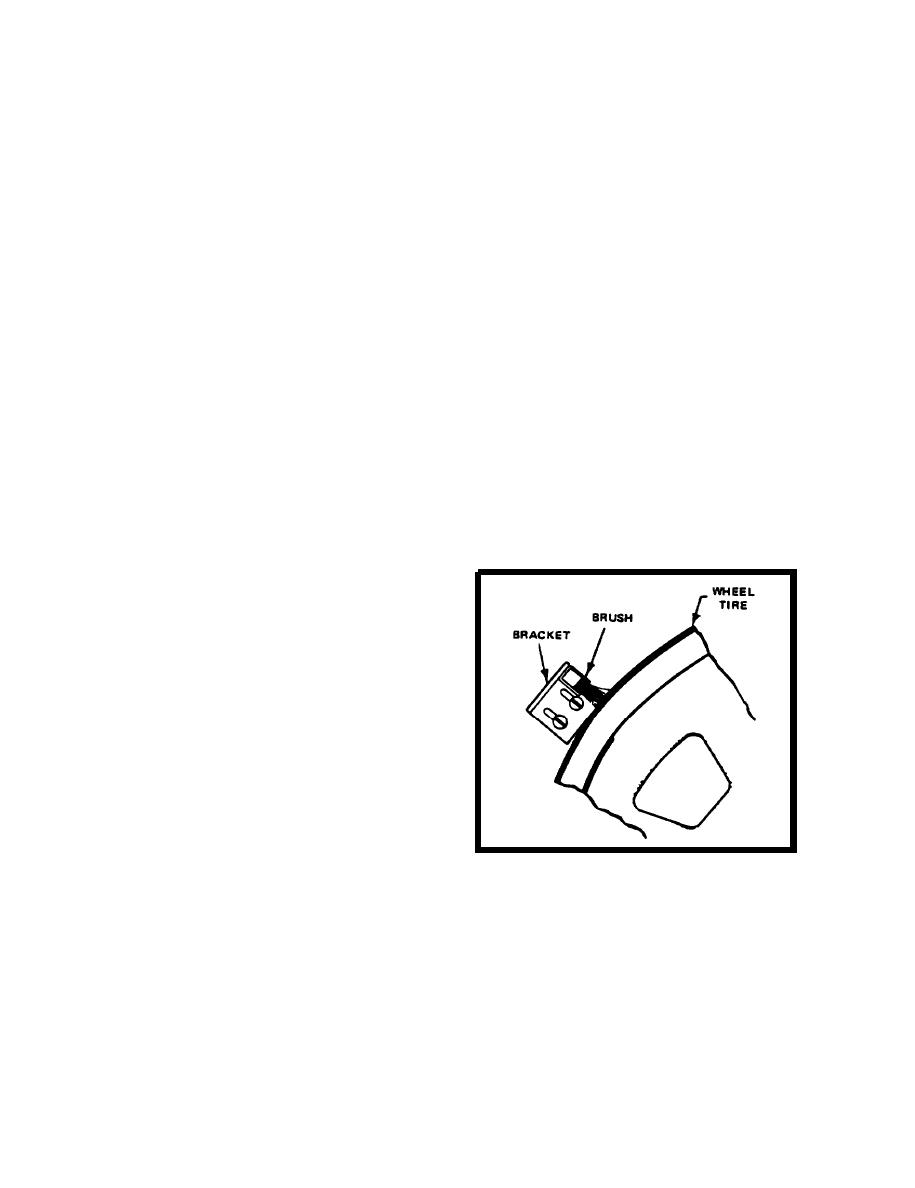

WHEEL BRUSHES

Check the wheel brush occasionally.

If it worn so that it is no longer

contacting the wheel face, loosen the

adjusting screws and move the brush

up to the wheel. Replace as needed.

ELECTRIC MOTOR

Main Drive Motor - Follow the manufacturer's instructions (see tag attached to motor).

17