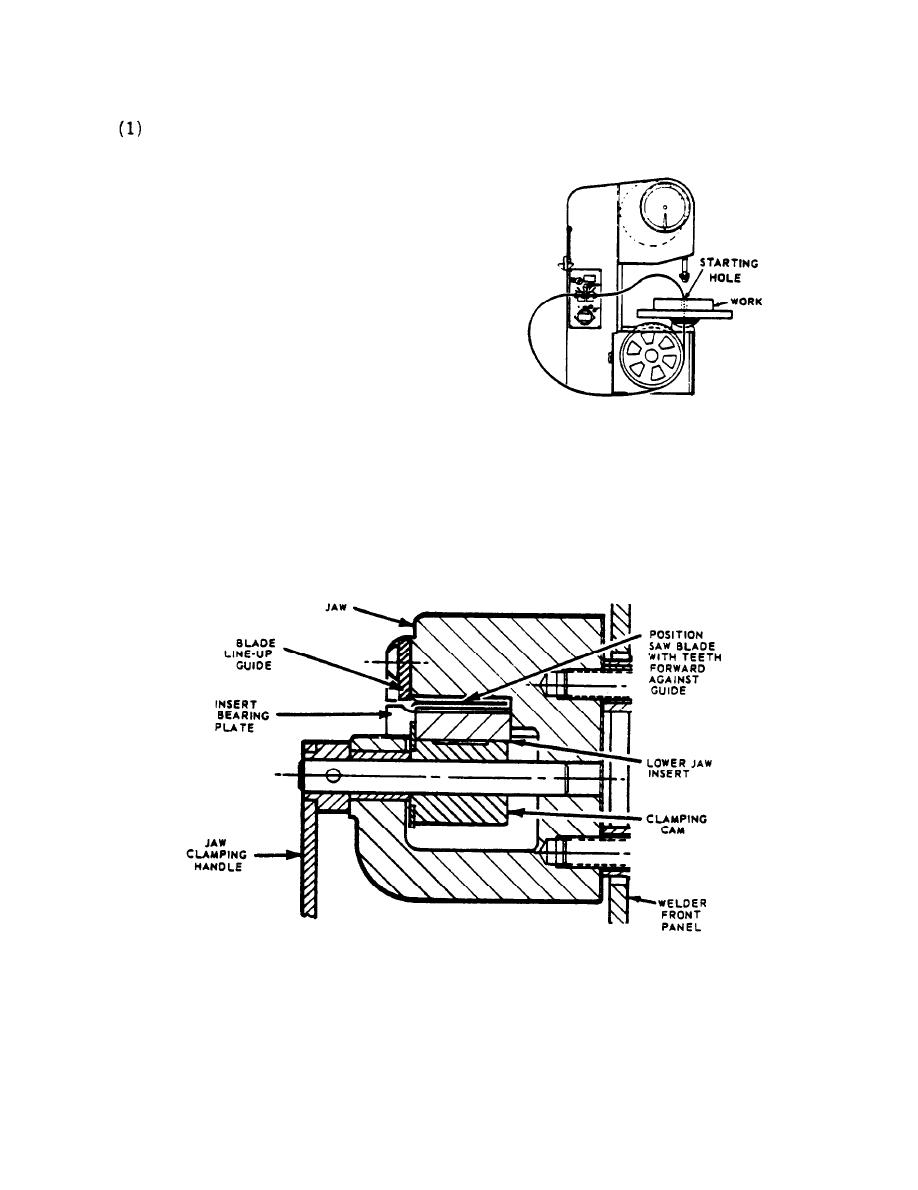

SAW BLADE ALIGNMENT BEFORE WELDING

For internal sawing, the blade is inserted through the starting

hole in the work. The ends of the saw blade are then brought

together to be clamped into the jaws.

When rewelding a used band -

cut out the old weld - it is

recommended that the saw

band contain only one weld.

NOTE: When welding band which

passes through hole in workpiece-

be sure to insulate bond from

contact with workpiece or table,

this will insure a better weld.

(2)

Place the band ends between the jaws with the teeth against the

line-up guides which are attached to the front edge of the jaws,

see sketch.

NOTE

Blades which are 1/8 inch or less in width are too

narrow to be clamped correctly when they are placed

against the line-up plates. Move these narrow blades

back slightly from the line-up plates and align them

by eye, then clamp them in place.

The jaws are clamped by moving the handles upward.

(3)

Check to be sure that the band ends meet in the center of the jaw

(4)

gap without any offset either in thickness or across the width. If

the contact across the width is not complete, remove one end and

recut it. A misaligned joint will cause an incomplete weld.

H-6