TM 9-3405-213-14&P

TROUBLE CHARTS - Continued

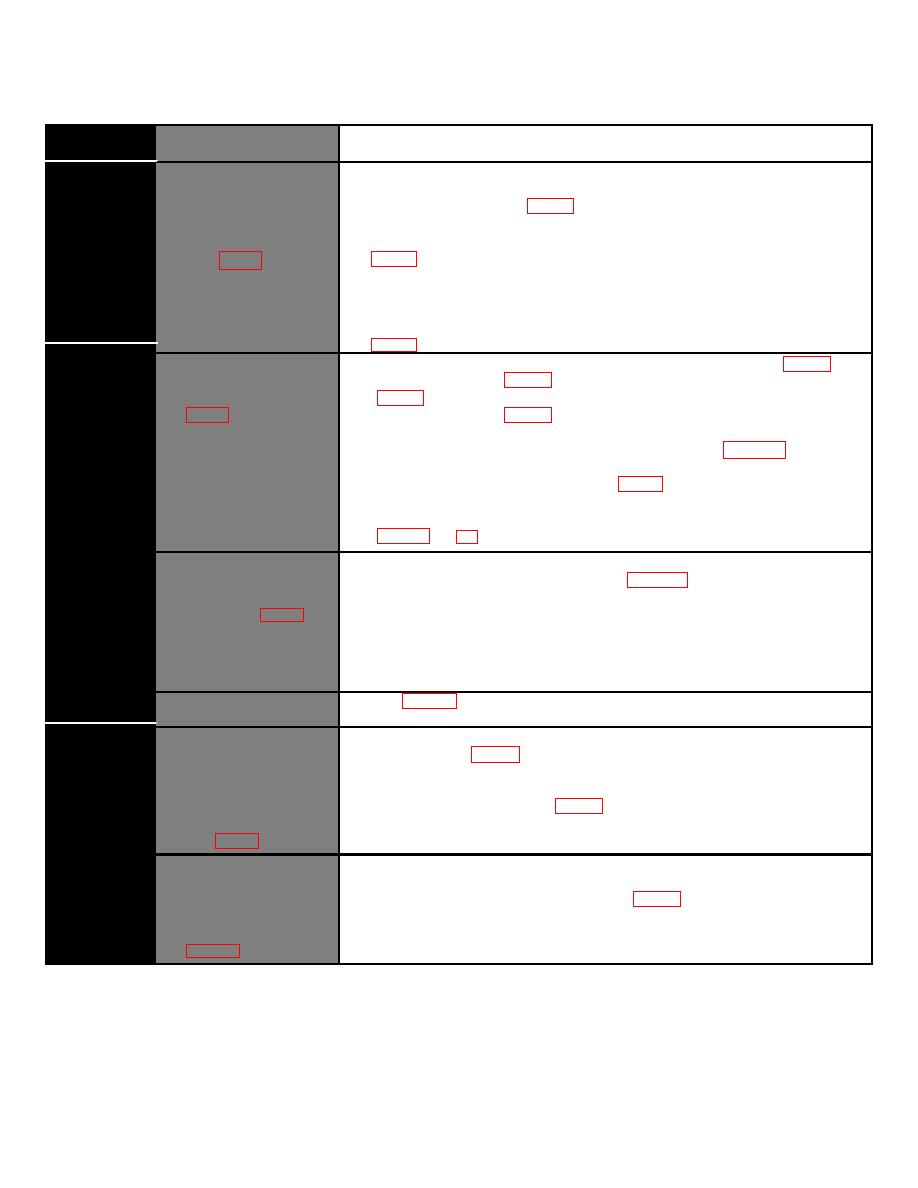

TROUBLE

CAUSE

REMEDY

1. 200283 feed

A. Feed control timing ring 200285 should be at bottom, that is, neutral

adjusting knob

position, when feed knob 200286 is turned to the left against stop pin,

incorrectly

which is zero position. Fig. 3 shows feed control timing ring on center or

positioned end feed

in zero position. If 200285 ring is in uppermost position, when 200286

cannot be controlled

knob is in zero position, the feed is fully open and is uncontrollable. See

See Fig. 3

B. To set 200286 knob to correct position raise knob over stop pins and turn

to the left as far as it will go. Then lower knob into place. Make sure

knob remains in correct position when replacing 275026 guard. See

2. WORN 200283

A. To check for oil leaks at this point, remove 275026 guard (Fig. 3) and

ABNORMAL

FEED TIMING

303019 tubing coil (Fig. 7). Remove a 1/8" fitting on 700057 lift cylinder

CASE COVER See:

FEED

Fig. 7 If 200283

feed valve 400163 (Fig. 4) and start saw reciprocating.

cover Is worn, the

DOWN

feed down of saw

B. If no more than normal feed down is evident (See Page 10 Item 3B for

frame cannot be

normal feed down), then leak must be in 200283 feed timing case cover,

OF SAW

controlled because

and this part must be replaced. See Fig. 7.

of excessive

FRAME

Leakage

C. 200283 feed timing case cover is always fitted with 200277 feed cylinder

(While saw

3. Worn 4 piston IN

A. First check for abnormal feed down of saw frame due to leak in 200283

frame is

200261 control valve

feed timing case cover (See Item 2A, Page 11).

reciprocatin

causing excessive

g)

leak. See Fig. 4.

B. If abnormal feed down is still evident, the control valve piston 300354 is

probably worn and the valve must be replaced.

C. As the control valve piston 300354 is fitted to the Control valve 200261,

these parts must be purchased as complete assembly No. 700015.

A. See Page 9 Items 3 and 4.

4. Insufficient oil in

reservoir

1. Dirt under relief

A. Remove 300403 cap on top of 200261 control valve and clean ball and

ABNORMAL

valve ball beneath

ball seat. See Fig. 4.

30043 cop on control

FEED DOWN

valve 200261

B. Reseat by topping ball in place in seat with soft Steel rod before

causing oil leak,

replacing 300403 cap. See Fig. 4

OF SAW

through ball check.

See Fig 4.

FRAME

2. Dirt in 300411

A. Remove 300414 cap. Then measure adjusting screw projection (usually

flexible feed valve

about /4") so that it can-be replaced in former position. Remove 300419

(While

body causing leak

adjusting stud and 400157 spring. See Fig. 4.

Machine is

through ball check at

idle or in

all times, See

Rest

position)

10