TM 9-3418-200-14 & P

The motor is mounted on a pivoted cradle (L, fig. 1) and power is transmitted to a shaft and from there to the drive

mechanism. Belt tension is adjusted by turning the cam in or out as shown in figure 1-A. The belt tension is released for

changing the belt on the four step pulleys by lifting the lever (M, fig. 1 and fig. 34).

The entire shaper may be mounted on a three drawer steel cabinet. The top surface of the cabinet forms a tray or built-in

chip pan. The drawers are provided with locks for storage of work, tools, and accessories. The cabinet should be bolted

to the floor for elimination of vibration and excessive noise.

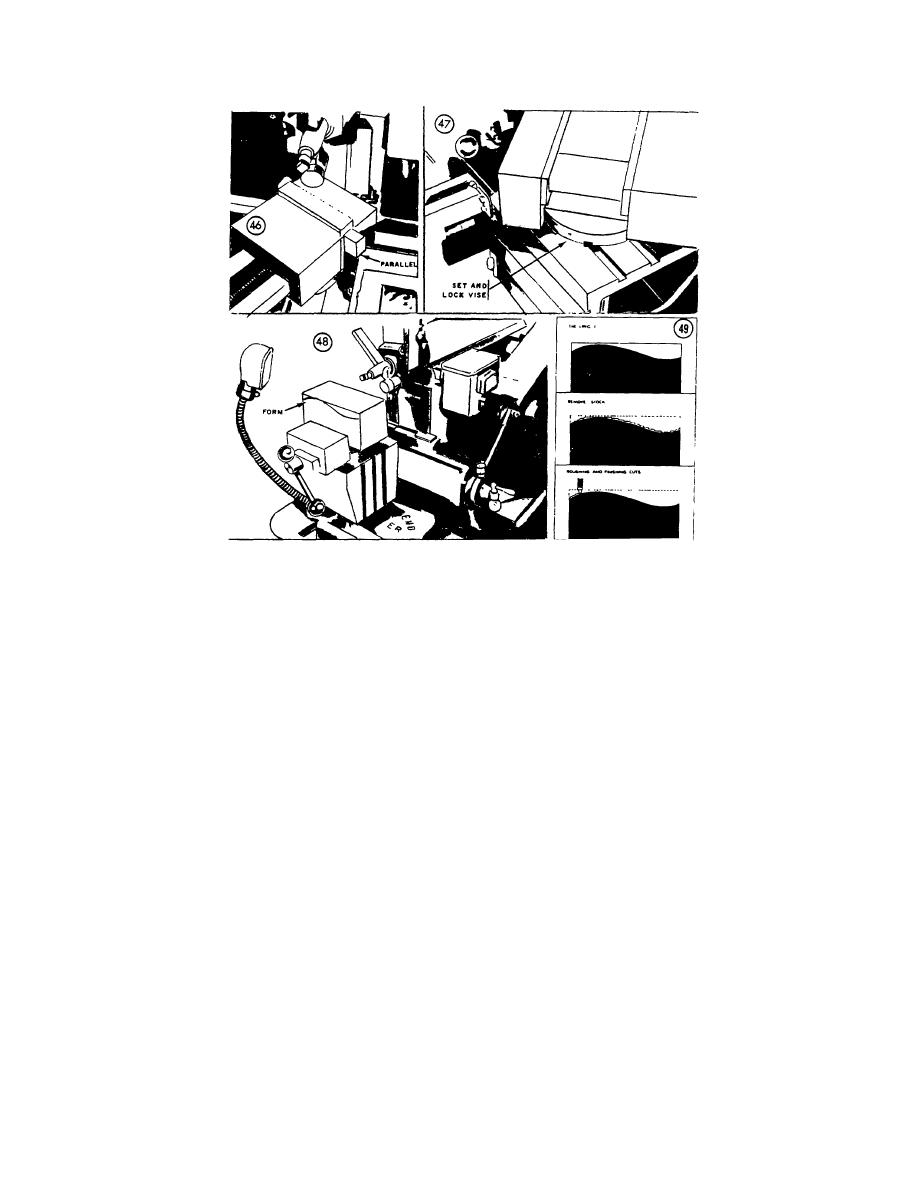

The first step after the work is mounted is to adjust the length of the stroke. The length of the stroke is regulated by the

width of the work to be machined plus 1/4 inch at the end of the stroke and 1/2 inch at the beginning of the stroke (fig. 37).

The 1/4 inch which the cutter travels over the end of the stroke allows ample chip clearance. The 1/2 inch at the beginning

of the stroke allows the clapper block to drop back into its normal position for the beginning of the next cutting stroke. The

first step in adjusting the length of the stroke is to turn the handwheel until the two arrows line up as shown in figure 35.

Next, remove the cover plate from the left side of the column and loosen the square head locking screw ( fig. 36). The

graduated scale is marked off in inches. Move the sliding block, set the marker at the correct length and retighten the

screw. Replace cover plate.

18