TM 9-3419-234-14&P

CHAPTER 2- THREADING HEADS

edge, thread distortion and chaser wear are minimized.

SECTION I

The tangential location of the chaser, m respect to the

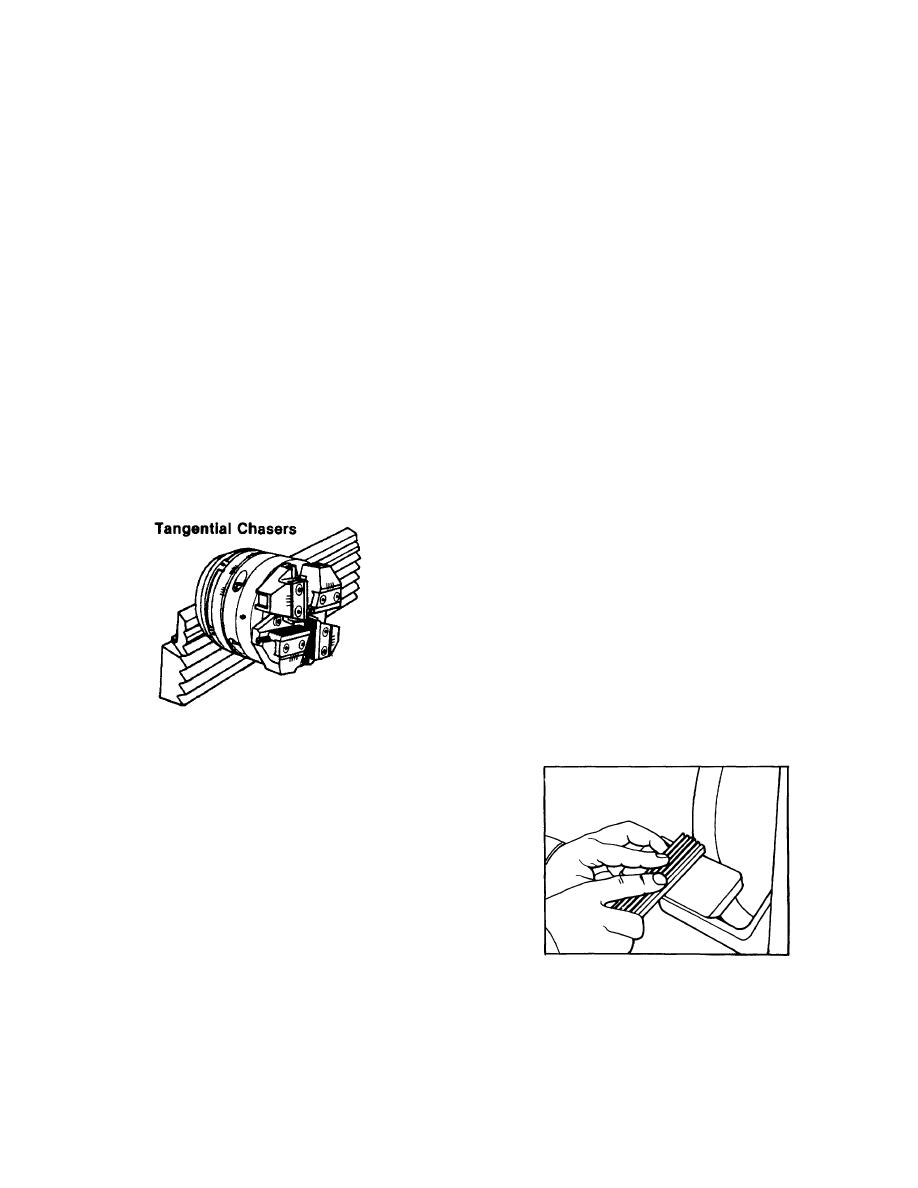

Threading Heads

work, places It in a direct line with the cutting action

a. Heat Treated Threading Heads are of the revolving

exerted in forming the thread. Rigidly supported in this

type for application to hand-operated, semi-automatic and

natural cutting position by the die head chaser holder, the

automatic threading machines. Of rugged construction,

resulting longitudinal absorption of cutting strains reduces

the heads provide accurate and trouble-free operation

vibration and chaser breakage.

over long production runs.

h. Depending upon the size of the die head in which they

b. Manufactured in four types, the R, S, T and RX, the

are used, Tangential Chasers vary in length from 1" to 6

Heads feature wide range coverage for threading

".

1/2". Their length allows a maximum amount of regrinding

diameters from 1/8" to 9 1/4 All types are yoke-operated.

and provides exceptionally long tool life.

The heads are available for standard applications,

i. During the resharpening process It is unnecessary to

receding chaser applications, internal trip applications,

remove the same amount of metal from each chaser in the

heavy duty applications and large diameter applications.

et. When one chaser is worn, chipped or damaged to the

c. Constructed of specially-selected alloy steels, the

extent that an abnormal amount of metal must be

Heads are recommended for threading up to and including

removed, it can be reground and returned to service

Class 3 tolerances and are well known for their ability to

although much shorter than the other chasers in the set. If

cut coarse pitch threads in a single pass. They have wide

a chaser is damaged beyond use, it can be replaced with a

range coverage, permit rapid et-up, give trouble-free

single new chaser without the necessity of replacing the

operation, are easy to adjust and of sturdy construction.

entire set.

The initial investment in a Heat Treated Die Head is

I- A simple grinding operation quickly and easily

relatively small, repairs are few, and with the use of

removes the few thousandths of metal necessary to

Tangential Chasers, tool inventories and tool cost

restore the cutting edge.

They normally can be

remaining low.

resharpened by removing .030" or less, depending upon

tool condition. As chasers do not require accurate

positioning when regrinding to assure that all chasers in

the set are of uniform length, the grinding setup is

simplified and resharpening time is held to the minimum.

k. Stock inventories are reduced as the same set of

Tangential Chasers can be used to produce all diameters

within the range of the die head requiring the same pitch.

For example, a 1/4" - 20 pitch ULTC thread can be

produced with the same chasers used to produce a 1/2" -

20 pitch UNF thread. Special chasers are required,

however, for each combination and pitch for special thread

forms as well as multistart high helix angle threads.

Fig 30

A simple grinding operation quickly and easily restores the

d. Further contributing to the economy of the Heads is

cutting edge.

the Tangential Chaser.

e. All Die Heads use chasers of the tangential type, a

design pioneered and introduced over 75 years ago.

Continued research and manufacturing experience has led

to the development of the present Tangential Die Head

Chaser, a tool without equal for accuracy, economy, and

production In thread cutting operations.

f. Tangential Chasers are manufactured from high

speed or super high speed steel which must pass exacting

metal-lurgical standards. Experienced heat treatment

assures that they will perform satisfactorily in service and

produce quality threads within the tolerance for which they

were intended.

Fig. 31

g The tangential principle of design - provides line

contact with the work to provide natural clearance

comparable to that of a lathe tool. Friction at the cutting

26